After my quad MTB build I still had one Trampa holy pro 15ply deck laying around, so I decided it´s time to build a second e-MTB.

I really like my quad, but to be fair, with it´s 25kg it´s just huge and heavy and some kind of flexibilty while riding gets lost with it.

Goal for this build was to hold the weight down at 12-13kg (including battery). That´s a pretty good weight for a solid e-MTB and a perfect base for any kind of jump activity.

The build is still in progress, so some components will be changed during this year, but here the base of parts I used:

- Trampa holy pro 15ply (custom colored)

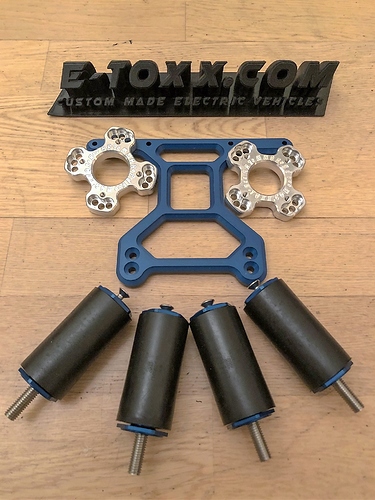

- Trampa Ultimate trucks with Etoxx Elastomer damper

- Trampa bindings with heel straps

- Trampa Superstar hubs with 8" wheels

- Motor mounts are from a forum member

- 3D printed HTD5M wheel pulleys

- 2x Focbox in 3D printed case and additional heat sink

- 2x ABS 6384 170kV

- DaveGA speed/voltmeter

- GT2B remote

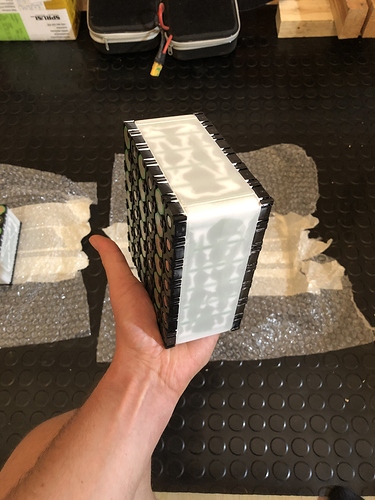

- 2x Turnigy heavy duty 6s 5Ah 60C lipos

- Battery case is a GoPro case for now, will be changed to a 3D printed case as well.

Ok, so “light” should be clear now, but why “white”…Trampa decks are usually dark…

Because it´s custom painted. With automotive color.

Let´s get some pictures into this thread as well.

The overall weight for now is 13,6kg and with it still in the range I want to. I will change the steel crossbar (yes steel…I dindn´t have had something else to hand) against a carbon fiber one. I might also change the 6384 motors to a smaller size like 6355 or similar which should result in about 800g less weight.

The holes of the deck are covered with 3D printed covers as I first planed to use that deck with an underboard tray.

During building I realiued that it´s not going to be a street board anyway so there is no sense for this bóard to mount the battery below the deck.

During the winter I changed the wheels to a DIY studded wheels. For those who interested in it, I will update this thread with a small “how to” comment in future.

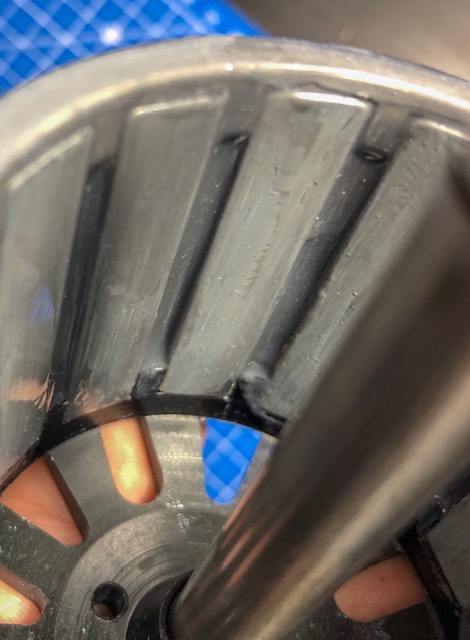

I also had massive problems with lose/broken magnets on APS motors. I fixed this issue by battle harden the bell of the motors with epoxy. I might write a small “how to” for this as well in future.

)

)