I just got a couple days ago a custom spot welder. It has tons of potential so i want to share this info with the community.

I live in a small house, we are swimming on electric and painting stuff so i can’t afford to have big machines. I looked for small custom spot welders on the net: microwave, car battery, supercapacitors… all of them too big or not what i was aiming for. Then i found this welder. It’s not a new device, was created time ago, since it is interesting many guys tried to buy it and the creator sold a few in his area but refused for a long time to ship overseas, i guess it’s looong time consuming for a low profit.

People insisted so recently he opened his hands to the world and i managed to get one for me. I’ll make a small review.

It’s made out of arduino custom shields. The creator is a korean genius named Aulakiria. He did many prototypes, ac powered…dremel size…this is the final item.

It’s powered by a 3s lipo, YES! lipo hates being shorted but he managed to limit the short to 16ms so no damage at all. The size is minimal 4x3x8 cm.

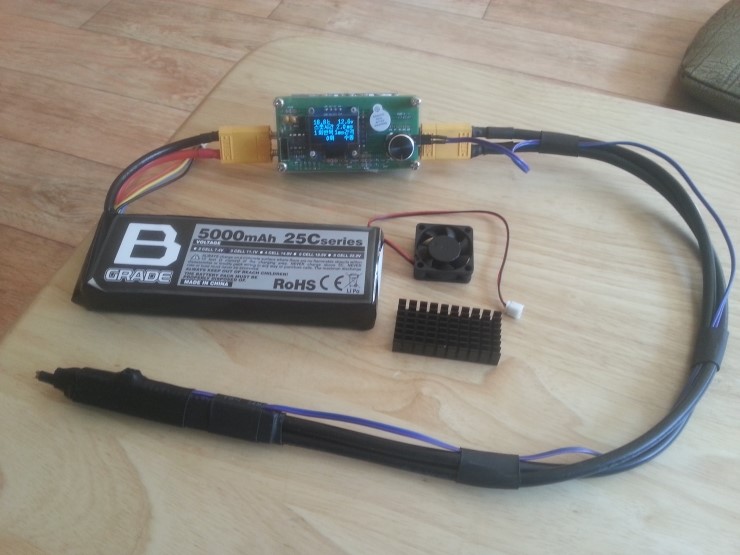

This is how i got it. The module, a pen, a momentary switch for manual use and a hakko solder iron (It solders as well) The shipping was incredibly fast 7 days from korea.

He sent me as a courtesy some nickel strips and the matching xt90 connector for the lipo.

everything fits inside this small box. PERFECT! my dream size.

All you need is a 3s lipo to use it. Just solder the xt90 and you are done. Aulakiria recommends top lipos, above 40c. It will work with whatever you have but the better the lipo the better the welds. He even did the demos with crappy b grade 25c to prove it.

UPDATE MARCH THE 25TH OF 2018 The new model has updated firmware and has become more resilient to 4s lipo use. Also many new users reported low performance on thick/wide tabs using unknown lipo brands or just crappy bricks around. Therefore i recommend ONLY top quality lipos. HOBBYKING Turnigy NanoTech and Graphene have been reported to be perfect. Use only high C lipos. They are often overrated or even exaggerated at C ratings so do not trust blindly the manufacturer claims.The thickness of the wire also matters.The continuous C is irrelevant. Look for the burst. Aim for 130C(burst) 5000 mah.

I use https://hobbyking.com/en_us/turnigy-battery-nano-tech-5000mah-3s-65-130c-lipo-pack-xt-90.html?___store=en_us

You can use several bricks in parallel in case you do not reach the amps required. Avoid wired adaptors for parallel. The transport will lose lots of amps. Use only adaptors like this:[/color][/color]

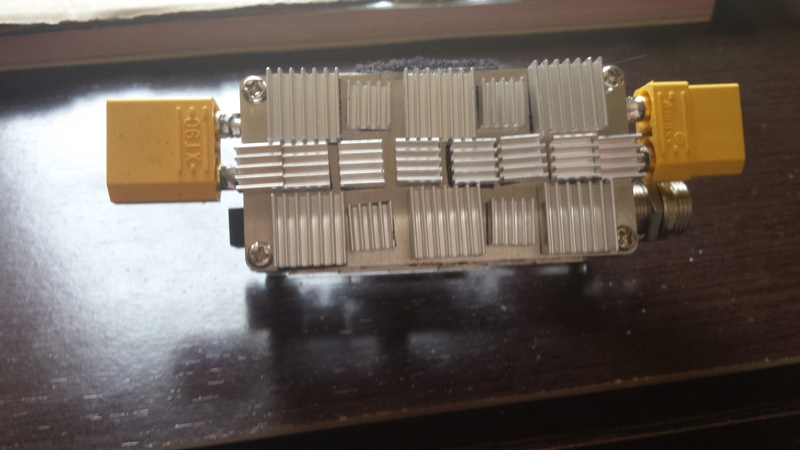

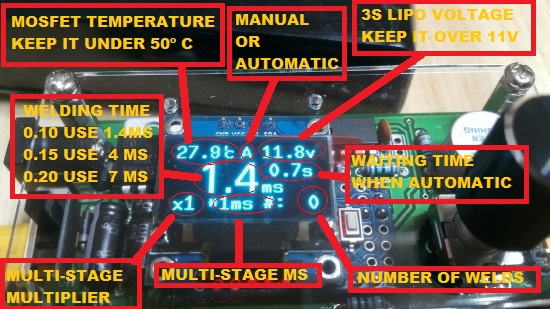

It has top quality IFR1404 mosfet manufactured in Korea and Taiwan. He recommends to keep the mosfet under 50º celsius. The shield has a port for a 5v fan. The left side is negative and the right side is positive.

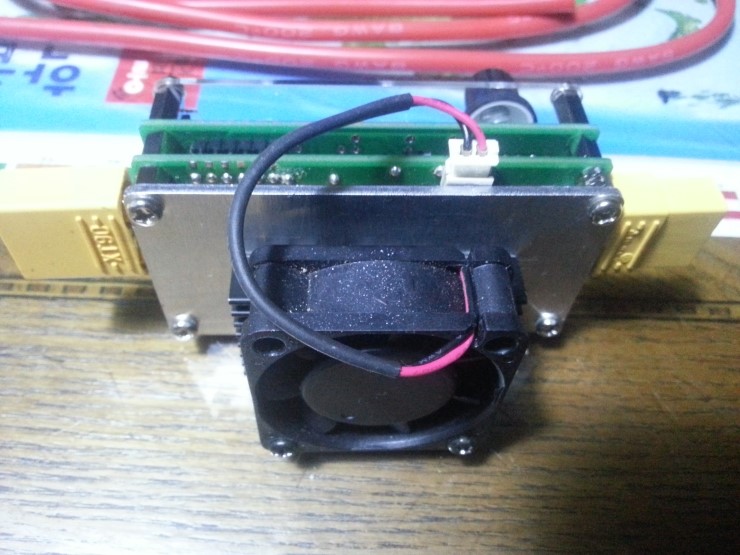

I installed a fan but totally failed. The temperature was always high, the welder stops automatically to avoid damage.

So annoying! My country is VERY HOT these days.

Well…maybe not that hot but very hot anyway so i installed some heat sinks on the plate.

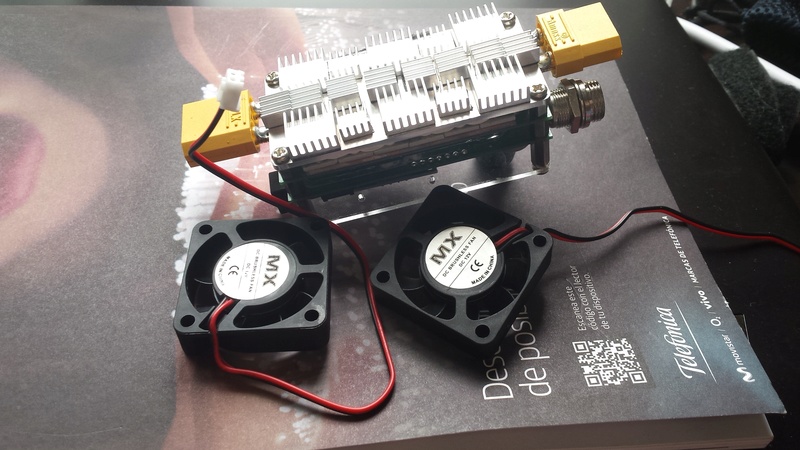

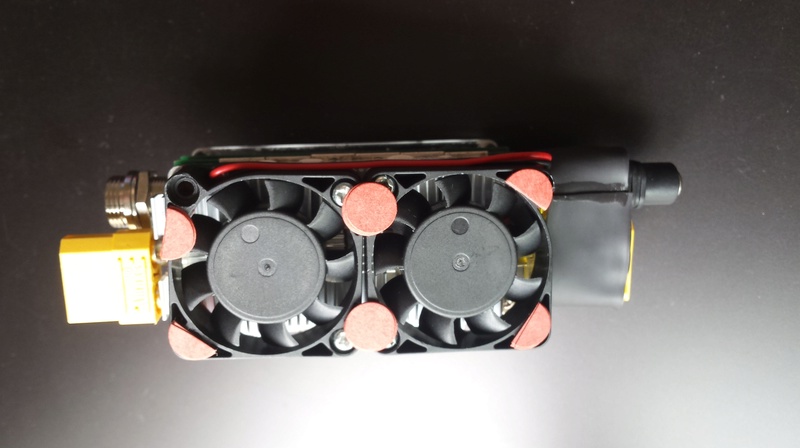

and two 12 volt fans.The temperature never goes above 30º celsius now.

In normal conditions any 5v will do a perfect performance. If you have a soft weather there’s no need to mod.

mod video:

I did a small video to show the performance:

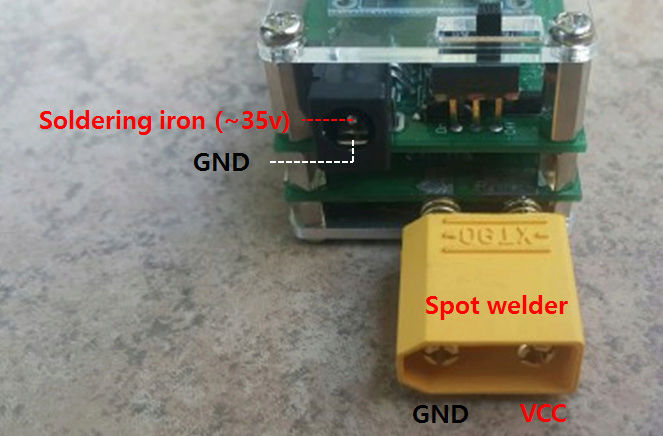

To use the hakko solder you need a power supply 12-35v. 19+ prefered .Any laptop power supply will do.

This is me testing the iron

This is Aulakiria himself using the iron:

Aulakiria translated the menu so we can read it. It’s easy to play.

using it:

in depth testing

How to make your own welding pen

Part two, welding pen with interchangeable tips

The welding times are usually:

For nickel strips

0.1 1.4ms

0.15 4ms

0.20 7ms

The machine is copper welding capable but requires 4s lipo. That is dangerous for the machine and yourself. The intense use of 4s lipo on high flux times may cause premature failure of the machine. Use it at your own risk.

copper times are:

0.1 5-6 ms x2

0.2 10-12 ms x4

Do not use copper unless you know what you are doing. The use of gloves and glasses are mandatory.

when the A is blinking is ready to weld in the waiting time you set. When manual set selected it will weld when you press the button. I plan to install a pedal.

My honest verdict:

if you are low on budget,have a small house and you just make small packs every now and then like me this is perfect.

If you have a huge garage plenty of room, you can afford semi-professional machines and/or you do intensive use of spot welder maybe you prefer something bigga hardda fastta strongga.

update february 21th of 2019

Let me introduce the MinispotA

Lee has built a mini version of the Boss spot welder.

take a look here

DISCLAIMER:

I am not affiliated, associated, authorized, endorsed by, or in any way officially connected with Aulakiria. THIS IS NOT A SALES THREAD. And i have no profit nor gain with this, i just think it’s a nice thing and i am sharing it with you. If you are interested on buying one just mail him saying you want one here aulakiria@naver.com that’s his paypal account as well. If you mail him be brief and use only perfect academic understandable english. Something google translator can deal with.

The prices are :

basic set : usd $ 95

Hakko T12 soldering iron Handle & Tip : usd $15 (option)

full set : usd $110

Paypal fees 3.5%, Usd-krw Exchange fees 3%…It is double charged so please consider the option send money to family/friend

shipping method

Global RR (KOREA post registered airmail) : $15 (20~40 business days)

Global EMS fee : most $27 (10~15 business days)

U.K (Great British) : $33

Italy : $38

https://m.blog.naver.com/aulakiria/220992039512

MAY THE 31TH OF 2019 i just did a copy and paste of this thread from https://endless-sphere.com/forums/viewtopic.php?f=14&t=89076 used to be https://www.electric-skateboard.builders/t/boss-level-custom-spot-welder/25980 at our old forum.

The purpose of this thread is talking about the machines designed by @aulakiria and spot welding with them.