You could also stick a dildo to your helmet and live up to the name knobhead, killing two birds with one stone.

you could man up to 120a per motor like i did 3 years ago

sorry i wasn’t impressed

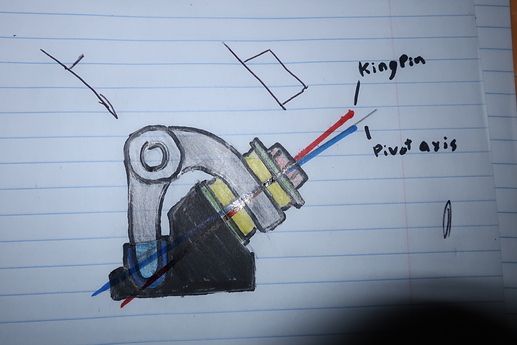

@CHAINMAILLEKID I would be interested to know how you came up with the blue line.

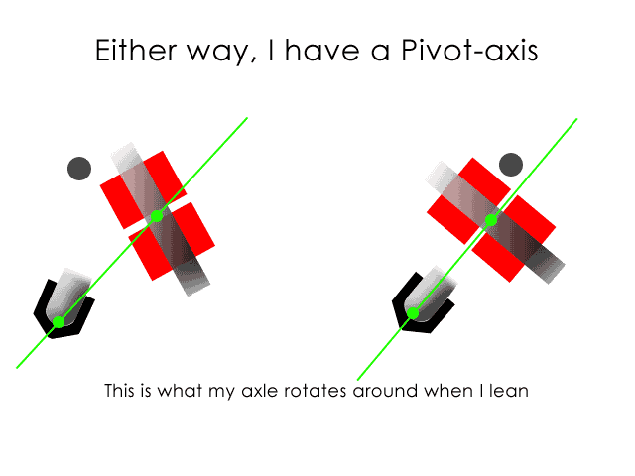

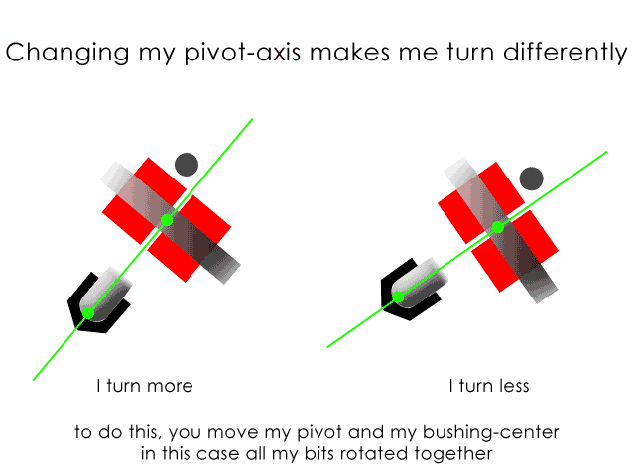

Simple, Pivot axis always runs from the center of the pivot to the center of the bushing seat.

Unless there’s something particularly unusual going on like an off axis queen-pin.

Here’s a awesome guide, which I’m sure somebody like you doesn’t need, but really tackles a lot of the misunderstandings people tend to have.

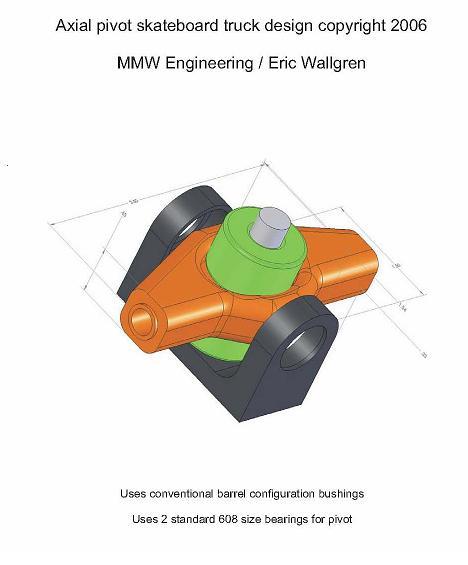

Wow, that’s interesting. Let’s rehost these images here in case the provider goes down

This is a bit beyond the scope of this thread but I wish it was this simple, any idea who the authority was that wrote that? I agree with the bulk of it but not all.

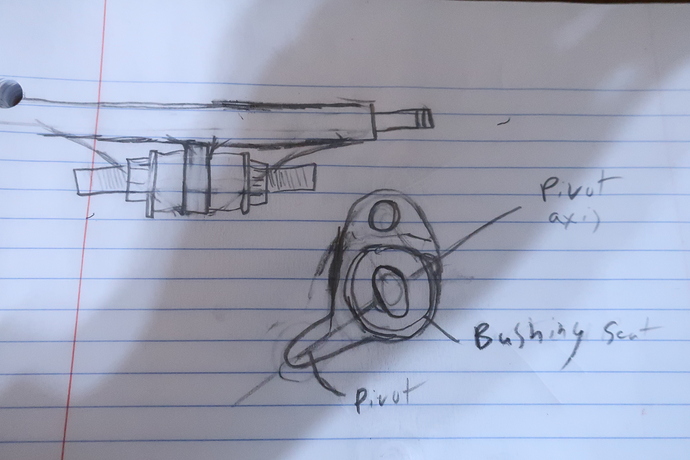

Too many things are not addressed. RKP pivots are normally a ball ended cylinder where TKP trucks are conical to allow them to rock in the pivot making them dive which means that at the far end of the trucks range, the turn ratio increases. I know of only 3 TKP’s that use a ball ended cylinder and their axle path is much closer to simulating a RKP than a TKP of the same geometry. Every elastomeric component that is involved in the truck is deforming at different rates throughout the turn and the theoretical axis in your article may exist in the trucks static state but as you turn and stress the system, the axis changes based on the overall component interaction. The pivot and king pin axis fight each other for dominance and control.

there is also a bushing and a wheel series, @b264 perhaps these deserve their own thread?

I have had these in a binder for years

I’ve got them on floppy disk

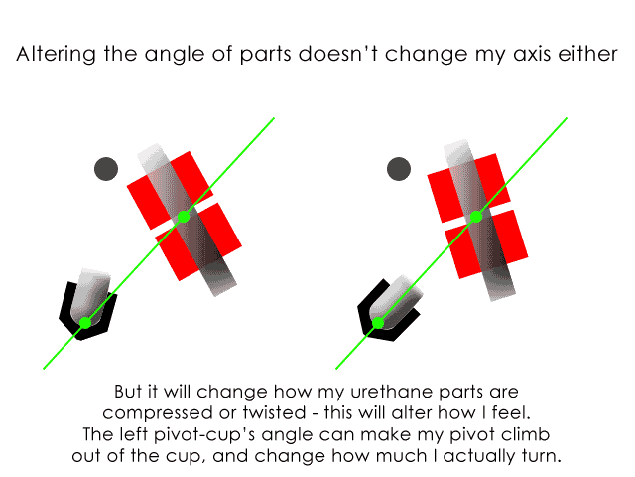

If the pivot climbs up out of the cup, the axis still is running from the center of the pivot, its just the pivot has moved.

But,

Firstly you’ve got to be doing some high level tuning before that comes into play. For a general purposes I think its better to ignore that. The angle change is smaller than most people need to account for.

Also…

I’m actually not entirely convinced that the pivots climb out of the cup in a significant way during actual use. I’ve tried to catch it in action on video and I’ve never managed to see it. Granted, tuning TKPs isn’t exactly my thing.

I think its just the axle offset of the TKPs that people are feeling, and also the different way that that an off axis kingpin affects bushing progression.

So just a little drawing experiment.

If the bushings on the kingpin are exerting a force to adjust the pivot by being off axis, then surely we can exaggerate the effect by bringing the kingpin really far out of line from perpendicular like you see in RKPs.

So here I’ve got this really crazy truck where the king pin and pivot axis are nearly in line, however still in the same order as with a normal TKP, with the king pin being more vertical than the pivot axis.

It is super late and I should have been asleep 4 hours ago, but I’m not seeing any means by which the kingpin can exert force to do anything to force the pivot out of its current alignment.

In fact it seems to me the less perpendicular the kingpin is to the pivot axis, the less influence the bushings have at all.

At this point instead of compressing the bushings, almost entirely what’s going to be happening the hanging spinning on them.

But looking at the pivot, almost the opposite is true.

Because the pivot is now not in the axis of rotation it cannot rotate and stay in the pivot cup. Its going to have to come out of the cup.

The way I have it drawn, as the pivot comes out of the cup it’s actually going to reduce the pivot angle, but flip it around so the pivot is coming out on the other side of the pivot axis it would increase the pivot angle.

So its not actually the bushing/kingpin angle that affects this extra mechanism, but just the angle of the pivot relative to the pivot axis.

Instead of double kingpin trucks, we should try to design some double pivot trucks. Like some sick hybrid between TKP and channel truck

edit: I guess that’s just Ronins then, eh

So you could actually modify gullwing type trucks, and instead of giving each the same pivot angle give one say a 30* and the other a 55*, and then use different hardness bushings to make a progression.

Edit:

Sidewinder type trucks.

Thinking about bushing rotation and placement.

What if you put the bushings on this way?

Have a floating kingpin to tighten the bushings similar to the fyre truck animation in the bottom image of Moon’s post.

There wouldn’t be any side to side slop at all.

Lot of weird problems to contend with, like rider weight. by I’m seeing all sorts of fun possibilities.

someones done their homework

i mean at this point why not just ditch the pivot cups and have 2 sets of bushings instead.

love the simplicity of this style of trucks, supprised we don’t see more in the DIY community.

I want to try them out.

Curious about stability over 30 miles per hour.

i guess this is kinda like the moeStooge 3link trucks but with the bushing’s on the base plate rather than the hanger, and keeping the centre pivot point rather than the link bars.

I agree but i cant think of why they would be worse than any other channel truck?