Let me just start this off by saying I hate walking.

As my main commuter board is heavy as a bag of bricks and pretty much requires me to wear heavy safety gear (because I can’t resist the urge to sometimes max out the throttle on my board (55km/h)), I decided that I want/need something that I can easily grab with me and not worry about having to park it somewhere and bring/wear a truckload of safety gear.

My solution: A pennyboard that I’ll Frankenstein together and limit to MAX 25km/h.

Parts list:

- Old pair of abused 90mm eBay hubs + trucks that I bought a ages ago for my first build. All I know is that they are 550W each and can take 10S. 120€

- 22" (55cm) crappy 7ply Pennyboard eBay deck 22€

- Clear griptape 10€

- Dual FSESC4.20 Plus 160€ + 50€ Shipping & Tax (Fuck)

- 30Q 10S2P Battery 98€

- Some generic charge only 10S BMS that I have lying around 10€

- Firefly Controller (built a bunch a while back) 30€

- Custom designed and 3D printed ABS enclosure

- NRF52 Bluetooth module 5€

I was a bit impatient and started modelling the enclosure for the deck without yet actually having the deck. Stuff from China takes a while to ship and couldn’t just sit around waiting, so I grabbed the measurements from the eBay listing and started to block out a few designs.

This is the one I ended up with:

I’ll share the STL files to these after my build is complete and I’m satisfied with the result.

As the enclosure itself is larger than my Ender 3 print area, I had to split it up into two parts and fuse them together later with ABS Acetone goop. Knowing that I will acetone vapour smooth EVERYTHING eventually, I went nuts with the ABS goop, fixed any printing imperfections and sanded everything down once it had hardened and dried.

Once I did actually get my hands on the deck I was happy to find out that it actually fit.

Flipsky VESC 4.20 Dual Plus came in the mail and I just had to test the electronics to make sure everything at least powered on. Since my battery is still under construction at this point, I grabbed a few leftover 30Qs and made a makeshift 3S battery to test with. After the initial config everything seems to work and I have a peace of mind knowing that at least my VESC is functional.

For some reason I decided to go against the standard of siliconing the battery together and wrapping everything in fish paper and tape. Instead, I 3D printed a hard shell - you guessed it - out of ABS.

The 3D design has canals in the shell for balance wires. I’ll end up sticking everything in clear shrink-wrap once I’m done with welding the battery and BMS assembly. Just waiting for my nickel strips to arrive.

Printing these shells in two parts because I refuse to leave my printer unattended for safety reasons and printing it as one single piece would take too long at 100% infill.

Each 5S pack consists of two halves and have been fused together with ABS goop into one solid block and vapour smoothed.

Battery size test fit:

As for the remote, I’ve fallen in love with Solidgeeks Firefly remote and I’ve built quite a few over the year and even altered the design to my own needs, for example a custom PCB for both the receiver and transmitter and added support for vibration feedback in the firmware.

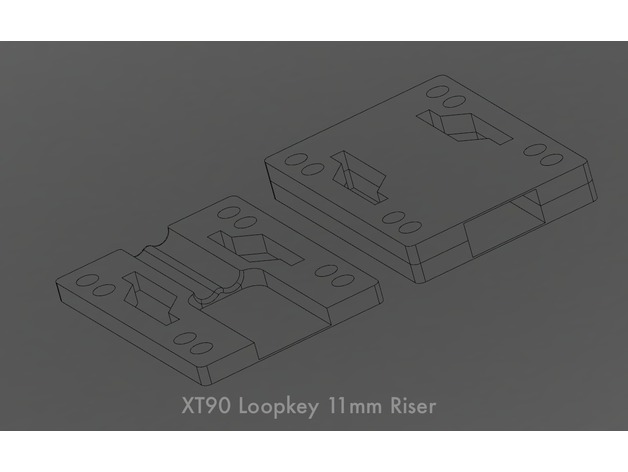

Recently I also posted a loopkey riser pad that I intend on using on this build, as I intend to ditch the power switch and use push to start instead. Only holes the enclosure will have are for wiring and charge port.

The enclosure still looks like crap, but since ABS is so easy to post process and treat it will be the final step eventually to add the finishing touches. My plan is to go all black and spray the deck as well.

To be continued…

I’ve blown fuses before with spot welders and it gets annoying very fast.

I’ve blown fuses before with spot welders and it gets annoying very fast.