Check this video I just make with the AWithZ UF20B welder 10.5 kW.

I find even the smallest leftover nubs when practice welding on used cells can really screw up the test weld results.

The probes can’t really push the sandwich flat.

I’ve been trying to weld on fresh cell nickel outside the leftover welds on the Samsung 50E. I dremelled those nubs in the middle flat trying to onky grind the 6 nubs, and test weld just the one pair closer to cell perimeter where it has not been welded before.

My flux free pure copper welds on those reclaimed Wintonic cells when I punctured the cans made me realize how important it is that the strips can lay perfectly flat on cell can, before the probes push down and weld.

I agree so much with you.

![]() I wouldn’t dare!

I wouldn’t dare!

I use 0.2 nickel ![]()

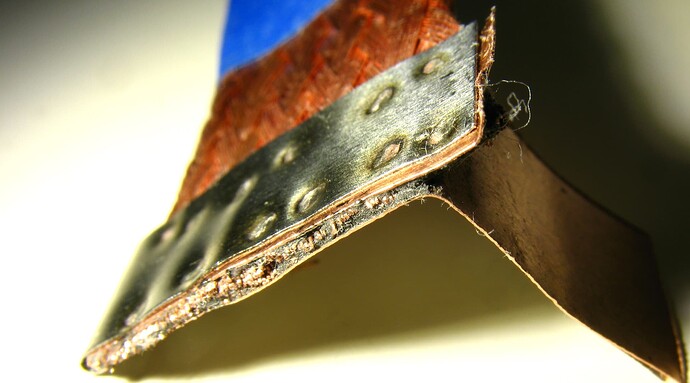

This 15mm wide / 1.5mm thick copper braid was compressed in my hydraulic crimper with its smallest Dies, for the biggest area of flat spots on either side of the hex.

I then sandwiched 0.1mm copper on either side, and a layer of 0.1mm Stainless steel on top of that, with flux between braid and first layer of copper.

These are ALL side by side welds, not opposition welds.

Gear 550, single pulse, 0.10ms preheating, pushing down on electrodes very hard.

There is basically no removing the copper sandwich from the copper braid, and this amount of welds is likely excessive.

I can’t peel it apart.

The braid remains flexible right up to the edge of the sandwich.

This only my second attempt experimenting with welding the braid.

I have not yet made an attempt to solder braid.

I think welding copper to copper opens up a whole lot of assembly possibilities.

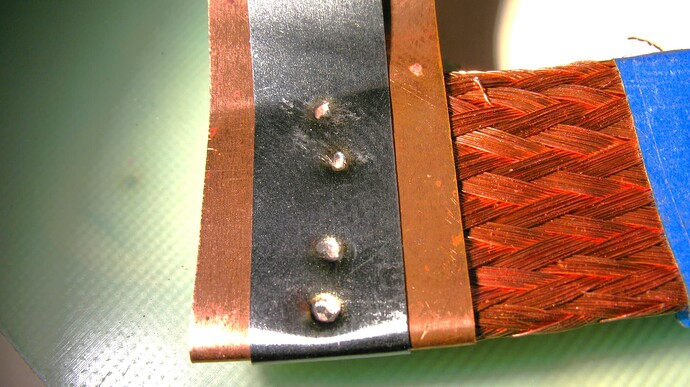

This was without any hydraulic crimper compression done before welding.

0.15ms preheat, double pulse 02ms interval, with a lesser amount of flux only in the middle.

The two sides of the flattened copper braided sleeve are able to be pulled apart, but the welded strips themselves are NOT coming free of the copper braid itself, not without ridiculous effort.

I did not push down with the electrodes as firmly either.

There are no opposition welds, with probes on either side of the strip.

I think even with fewer welds, that the amount of surface area between copper strip and copper braid in direct contact between the welds is very large, and many more welds can be added, side by side, and opposition welds too.

I have having difficulty seeing issues with doing this.

if the issues with braided sleeve in esk8 batteries was the difficulty of soldering without solder wicking up the braid and making it crunchy and brittle, welding copper to copper eliminates that as well as potential significant cell heating when soldering braid to the folded tabs.

Since Solder itself is not nearly as conductive as pure copper this seems like another way to reduce overall pack resistance.

Quick AI overview : …

A 1.5mm x 15mm copper braid is roughly equivalent to a 10 AWG to 6 AWG solid copper wire, but its performance differs in key areas like flexibility, ampacity, and resistance. A solid wire of the same nominal gauge number will generally have a higher current capacity in standard applications. The braided design makes the wire highly flexible, which is a major benefit for certain applications.

Ampacity comparison

The ampacity (current-carrying capacity) of a 1.5mm x 15mm copper braid can vary, but manufacturers typically rate it between 90 and 120 amps. This is comparable to an AWG solid wire with a larger cross-sectional area.

| Conductor | Cross-Sectional Area (mm²) | Ampacity (A) |

|---|---|---|

| 1.5mm x 15mm Braid | 22.5 mm² (nominal) | 90–120 A |

| 6 AWG solid wire | 13.3 mm² | ~95 A |

| 10 AWG solid wire | 5.26 mm² | ~55 A |

Forgive me, what is an opposition weld? Just trying to keep up

Opposition weld is the electrodes on either side of the materials being welded together, vs Side to side like we do on the cells.

I am not sure if there is a more acceptable term for this

I flattened some oxidized impure dirty 12awg copper wire in my hydraulic crimper, put it on top of a Dab of flux on top of a dented Wintonic cell can, under some 0.1mm stainless steel, and hit it with a double pulse, gear 650.

Wrapped the wire around my hand and the cell in the other.

Super strong, basically have to rip the 0.1mm stainless steel, and it does not rip easily.

I guess I have to try similar with tinned 10AWG silicone wire at some point.

Just a side note…any solder that’s in the braid, and not between the braid and the copper, will lower the resistance of the connection since the solder is filling in areas that would normally be just air.

But, yea, we have to be aware of stress concentrators and the point where the solder stops cannot be flexed a lot. But that is the same for where just plain braid would exit the copper strip. Vibration is bad always. ![]()

The strands of the braid are also significantly less flexible than the fine strand silicone copper. It is my opinion that the flexible braid does an amazing job of being conformed to a particular use - but shouldn’t be relying on it for flexible connections points. Use it to make a rigid connection but not high flex spots

There were quite a few failures reported on here of braid crossing a flexible enclosure joint and failing after some use. Like led strips - can be flexed into an installation but not used in a flexible installation if that makes sense.

I should have perused this thread^ earlier.

I am not sure exactly how much flex my future batteries will be subjected to.

My first battery was built rigid for a rigid enclosure and enough padding that the enclosure could flex around the stiff battery. But this was also for a stiff deck.

I am using that enclosure strapped to a super flexy deck now, and that stiff battery survived, but I feel much better with dual 14awg silicone wire between p groups on my newer pack

I am not very impressed with the copper braid I bought, and it is several degrees of overkill, but in an Eve 40pl 10s1p, which will be my next build, Ill just stick with silicone wire.

But can I flatten it and weld it instead of soldering it?

With copper’s much greater thermal conductivity, soldering Series connections likely introduces way more heat than desirable to cell than would the same dimensions of pure nickel in the folded over tab method, and soldering before welding introduces some more difficulty.

I wonder how the tinning on silicone jacketed wire affects conductivity. If each super fine strand is individually tinned, then would current be less apt to flow outside that strand to an adjacent strand?

I’ll experimemt with flattenening and welding silicone wire this evening.

As long as the solder isn’t the only current path, but is used properly as a means of joining the wire to the nickel - effectively just holding it in place. Solder is less conductive than copper or nickel but it is adding to the cross section available for current flow. (No skin effects on dc) this means when done correctly the effective resistance is reduced when a wire is tinned because it is resistance in parallel.

You could run into issues with bad solder joints but this forum is pretty good about making sure no poor joint goes un heckled ![]() if i got nothing from this forum except solid criticism of my solder joints at every uploaded photo i would be thankful. My solder game is significantly improved since i took my place under the bridge with the other solder joint trolls

if i got nothing from this forum except solid criticism of my solder joints at every uploaded photo i would be thankful. My solder game is significantly improved since i took my place under the bridge with the other solder joint trolls

Any solder added to any stranded wire in any form reduces the resistance of that wire.

The resistance of the total cross-sectional area of the copper strands does not change if the strands are all together or completely separate. The strands will divide the current based on the resistance of each strand, which will be pretty much identical.

If the strands are all touching each other, no solder, then current can flow everywhere but the cross-sectional area of the wire doesn’t change so the resistance stays the same for this (vs separate strands).

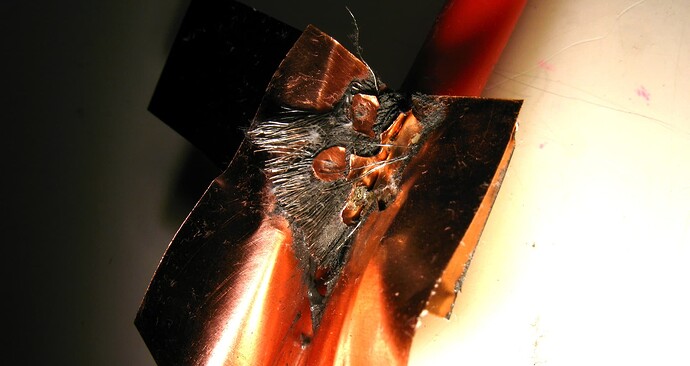

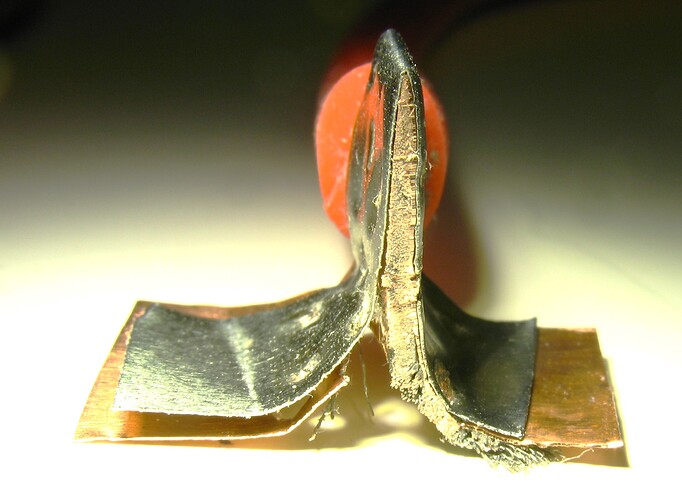

I Flattened some 10awg silicone wire in my hydraulic crimpers, sandwiched it in 0.1mm copper and 0.1mm stainless steel, with flux, and gave some parallel welds on each side.

Single pulse, gear 550, No preheating

The sandwich was welded to the fine stranding, but not all the way through.

I closed it back up and did 2 opposition welds, and this does get all the way through.

Was able to peel the 10 awg apart, but the 0.1mm copper and 0.1mm ss was bonded well to each half

This is running my tin snips through some parallel welds.

I Did not nail the settings, or technique by any means.

The ‘flattened’ stranding is not really flat, it is tapered towards the edges still.

I dont know if the flux does anything.

The downward pressure on parallel welds, and clamping pressure on opposition welds plays a huge part.

Overall, It is totally possible to weld copper strip to silicone jacketed super fine stranded tinned wire.

Developing a technique to do a clean job repeatedly will take some trial and error.

Part of me feels like there is definitely merit to this approach and another part of me feels ‘eeewwww’

I personally like it very much and I will give it a try in future projects. I see so much use for this.

There is definitely some eeeeew factor when peeling apart the copper layers and seeing and smelling the fluxed stranding.

The Wiedemann–Franz law says there is a close relationship between thermal and electrical conductivity with metals, so if copper is roughly 4 times more electrically conductive than nickel, it is roughly 4 times more thermally conductive too.

Soldering series connections to the folded over tabs has to be transferring far more heat to the cell(s) using copper, than it would with an equal size conductor of pure nickel.

Is it a consequential amount of extra heat? I don’t know.

I employed a heatsink on my most recent build with 0.1mm copper under 0.1 NPS, which was the maximum my purple spot welder could reliably weld, but I was unaware of using Stainless then.

This battery is performing wonderfully, so far, but 0.2mm and the thicker copper I can now weld, will take more heat to solder and thus transfer more heat, more effectively, to the cells.

So spot welding series connections seems desirable for the lesser heat introduced to cells, but certainly not as visually rewarding as flattening 10AWG into a molten blob of Kester 63/37.

I have ordered some 0.07mm 304 Stainless. In theory it should lessen the power required to sandwich weld even further, and the 0.1mm SS sandwich cap seemed so strong that being 30% less strong seems acceptable.

I am still intrigued with the amazing strength of the 0.5mm 400 series stainless steel weld experiments, and how it seemed to press the copper flat and wide to the cell.

So I am also wondering about 0.2mm 304 stainless and if less welds can be just as strong with the same surface area, or even perhaps a greater amount of copper in direct contact with the cell.

Definitely something to keep an eye on as far as heat transfer with copper, but it also goes both ways. I would think sinking the heat out of a connection should be just as effective. I know when i use my big copper buss bar as a heat sink i can cool a joint too fast if i apply it too soon after soldering braided connections.

If i put the heat sink on the braided wire 1/2” from the joint it will keep the braid from wicking up solder even if ive over applied flux - just doesn’t get hot enough to wet it.

Amazon delivered an empty package this weekend - my copper is in another castle ![]() . Should be starting some tests this weekend. If the last of my supplies arrive soon

. Should be starting some tests this weekend. If the last of my supplies arrive soon