pulling the stator youre making a worse motor in that the airgap thickness is essentially increasing. you could similarly add crappy weak magnets and would be the same as pulling the stator.

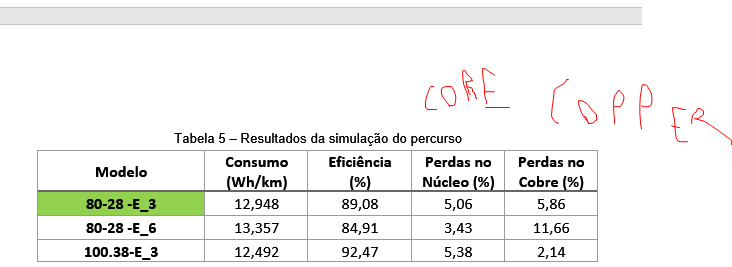

pulling the stator does show there’s a lot more potential in the motor as far as heat produced to POWER output only in that it is increasing speed. a lot more potential is possible in all our motors and we all are barely spinning them and theyre all heavy with copper losses where if we want to get the most power output we’d ideally be balancing copper and iron losses, but doing it in a way where youre decreasing the torque to amp relationship at the same time is counter productive.

if all of us could spin our motors at like 20:1 gearing, with our .2 or .15 millimeters of laminations of great electrical steel, we could get more power to heat produced but no one is able to fit the gear.

if anyone spins their motor at its top speed with no load on the bench …that is all the iron losses the motor will produce even under a load. the difference loaded or unloaded i read is negligible as far as iron losses produced. so if you get maybe 2 amps at top speed doing that…and when youre riding youre often hitting maybe 30 amps …its very largely copper lossses and if you swapped the gearing for 20:1 maybe youd get 6 amps at top speed no load but the burden to produce torque by the motor is greatly reduced so that current draw goes way down