I used to have the problem that as soon as my phone screen went off the download would reset. Try keeping your screen on for the whole process.

I’ve always use unity app… What would the benefits of switching to vesc tool and getting fw5?

K

I have some 3dservisas gear drives and flipsky 6374 motors

What is the best way to cut the shaft and how long should I cut it?

They are fatboy eco 1:3.5

Thanks

18mm

its just like all other vesc, fw5+ has HFI, smart reverse and some other fixes, but I personally don’t update unless I have to have whatever new feature is available, just me tho

Thanks just saw

Also I don’t have a dremel so would a hacksaw or something similiar work

Hacksaw probably works, or a lathe if you want a clean cut.

Just make sure not to get any metal shavings inside the motor.

Don’t have a lathe and I expect all machining shops are closed are here atm

@athrx maybe you know?

I’m uploading it from a laptop. As I watch it, it loads to about 6% then stops and times out.

looking to use a lathe from someone in uk

thanks if anyone can

Maybe try with the phone?

Very slowly with an angle grinder and the proper disc. Tape the shit out of it, cover every hole, mark exactly the distance you need starting from the mounting face and give the angle grinder to someone who won’t set the house on fire to do it. Tell him to finish off the sharp edges afterwards too.

You will want the slightly thicker steel cutting disc for this btw

solid advice right there ![]()

The kickback alone from starting the grinder with a heavy blade can launch it out of his hands. Shit ain’t fun

Example:

Mysteriously everyone who asked for a free blade from the company hates my guts. Wonder why

The tiny ones are fine for precision work, the big ones, not so much

Hi guys,

I’m having issues with my motor in which it seems to run ok until after a short period of time, or even turning the motor seems to brake and slow down and sometimes begins to stutter, with it moving back and forth very quickly.

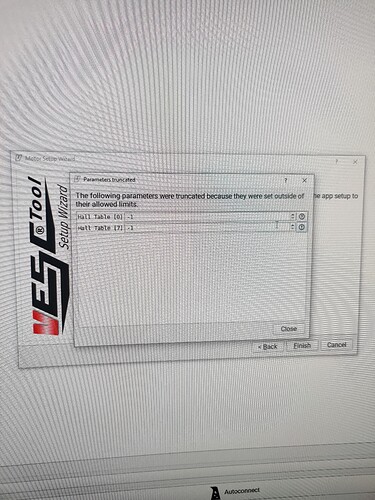

Could this be something related to the sensor wires. I have a HK SK8 149kv 6374 motor that is sensors, being powered by a flipsky vesc. Maybe they are pulling when turning and becoming loose need the motor? I have plugged it in to vesc tool to see if I could set them up again. And got this message after detecting and applying parameters:

Could this be my issue? Any help would be much appreciated! Thanks

Sensors could be fucked, but you should also check with a multimeter to see if you have continuity between your phase wires. If you do, then you have an internal short. If your motor mount bolts are too long, that can cause a short.

Try not using the sensors at all

If I do have an internal short, would running the motor without sensors as @b264 said be ok? Or would I need to replace the motors?

No.

Try the hand test