Is there a reason why this stuff isn’t mainstream tho?

Why are so many people not running valve caps on their pneumies?

Lazy

They get lost

Who knows lol

Weirdly my Lacroix came without them.

Other than that, are all the center motor shafts with keyways the same?

When I buy some new motor pulleys, is there a universal type?

They’re not all the same, but they’re usually pretty similar. The main thing to keep an eye on is the length - that can vary a bit, and a shaft that is too long or too short can cause issues.

The most common ones are 8mm ID (for an 8mm shaft) with a 3mm keyway. There are 10mm ones too.

3 to 4 inches

Thank you kindly!

Hey guys, quick question for ya.

I am programming a stormcore 60d+ with vesc tool, and I haven’t done this in a couple years lol.

Do I have to write my motor settings two times, once ‘per side’?

I wrote settings into motor(stormcore_60D+): Local, and they didn’t write to

motor(stormcore_60D+): 2

So do I split my amps per can-device?

So 50a motor per can device, 25a battery per can device?

or in motor(stormcore_60D+): Local, do I write them as 100a motor 50a battery?

Sorry if this is confusing, I am a little confused lol

Also is there anything else I should change in vesc tool besides Duty cycle current limit start?

yes

they’re each separate, so it depends

those motor amps are pretty low, what motors and battery are you running?

If your battery can do 100 amps out, then set it to 50 per side. If each motor can handle 100 motor amps then do 100 motor amps per side. On my Evo with a 12s4p p42a, I was running 100 motor amps/50 battery amps per side.

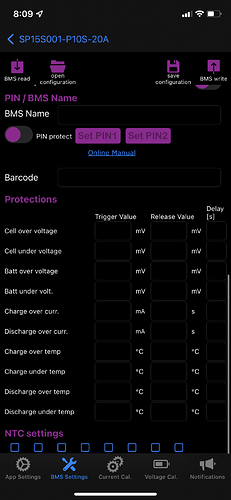

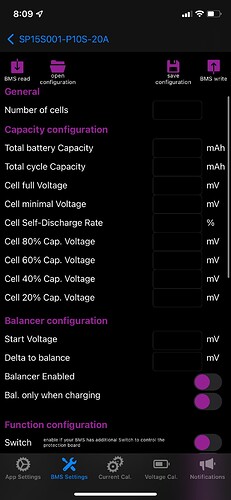

Click read bms to get settings

just tried to run vesc tool on my plut cause I changed a motor, followed all instructions from bioboard but when running detection I get a error message “could not read motor configuration” what does this mean?

ok the real noob question here is: can I just swap a motor with the same model without going through the detection process again, and merely change direction if the changed motor turns the wrong way? cause I got a “same model” replacement motor and there’s no manual for esk8 in general to get this kind of info out to customers.

Thank you for your help!

I am running the same 12s4p p42a with 6384 motors.

I figured I would lower the power as I have not ridden a board since pre-covid.

I suppose I could always just use the freesk8 app to tone the power down though!

- if it’s an ABS enclosure then cover it with fiberglass first, ABS will break at the boltholes

- mount the enclosure first

- epoxy wire connectors through the enclosure walls

- use either foam or RTV silicone or both to keep the stuff inside from moving around

- use butyl tape for waterproofing

You can start out at 50 motor amps/20 battery amps per side. That’s still more power than any prebuilt board on the market but shouldn’t overwhelm you.

Definitely doesn’t feel like ABS, more like a hard plastic. I got everything measured for the enclosure, where it’s going to be, how many holes will be drilled, etc. butyl tape is a good idea. Can I put that on the inside for the charge port and power button? As well adding it with the foam on top of the enclosure when mounting it to the board. I got no idea how to work epoxy so I’ll be using Velcro + foam for everything, how I got it mounted is pretty spacious and just tightening up some wires would make the inside nice and clean