I’m not sleeping very well atm, I’m on my period.

THIS. This happens with wet dirt and grass too. packs into the teeth and forces the belt to expand. I popped 15mm belts like this, its the only way I’ve been able to pop them.

Alright so what I got out of this thread was that

- The tag serious might be helpful lol

- This is a good idea and should be done

- People want bigger wheel pulleys.

- Motor guards could be added

I laughed out loud at this one

I laughed out loud at this one

I want smaller wheel pulleys and bigger motor pulleys- we might just have a vocal minority thing here.

16:32 isn’t good enough, 18:32 is perfect imo.

Bigger wheel pulleys allows for bigger wheels which can help with the clearance concern mentioned above.

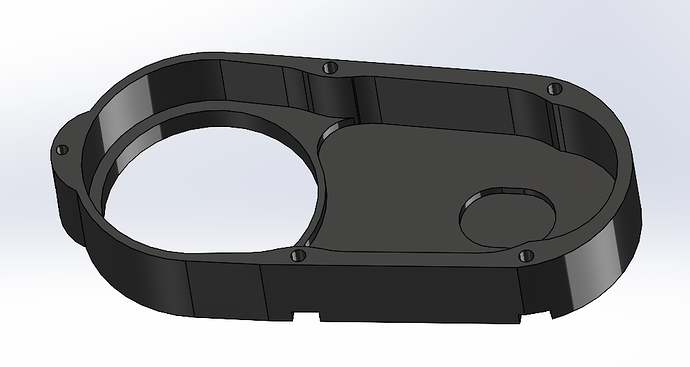

At first I was thinking bolt on different tooth count pulleys, but space is pretty tight in there I assume, and it would increase the complexity and weight. Also having bolts that could come loose in there where you can’t see would be bad.

So if additional pulleys could be produced for a reasonable cost just switching the whole part is probably smarter.

on ahmyo akashas maybe.

38 is big enough. Unless you plan on making multiple case sizes. We’ve already eliminated smaller wheels, which i’m sort of a fan of for mall grabbers.

This would be a great addition to the lineup man. Stoked to see how it all comes together! Seems like you have put a great deal of thought into the design and that is quite commendable. Being able to somehow check belt tension as @deckoz mentioned would be nice. But it also wouldn’t be the end of the world to have to remove housing in order to perform this task. As is the case with gear mesh on a gear drive system.

Since its enclosed fully you could probably figure out a spring loaded belt tensioner that could be adjusted with an Allen wrench.

Yeah I guess I had already imagined this in my head as being the process in which to go about install

I guess the main problem here would be the use of a shoulder bolt making this process substantially more difficult than a studded axle?

I had the exact same thought. I have been telling Kevin to go for a standard or extended axle instead of shoulder bolt.

That’s not what she said. ![]()

38T would be the bare minimum I could use, and I’d very strongly prefer 40T over 38T and weakly prefer 42T over 40T

People who use six shooters

Fuck plastic

Just up them motor and battery amps

hey that’s Ace’s witchblade!

Yeah, after the bomb he took a few of the Philly squad on a badass ride around the city and central park. That thing is a BEAST. He was fucking hauling.

Yeah 38T is the most I can get with a 70mm diameter cover. You can see the wall of the cover near the pulley is already thinning out. Any thinner will make machining difficult. I am running into unavoidable limitations here. Personally something like 15/38 has plenty of torque for me, and like I mentioned earlier, these are designed for dual motors seeing as they’re high performance belt drives.