Was under, didn’t provide enough amps to the VESC to power the motor so I just set it back to 45 amps as I had it before

Just literally put dish soap on and around the bushings, yeah?

Yeah I normally put it under the washers too because a lot of the noise is often the washers rubbing against the bushing, but just lather em up and see if it helps.

In case you want to preserve your dish soap, shaved parafin wax is great for reducing bushing / washer / bushing seat noise.

WFB bushing from riptide come pre-lubed fyi.

I take them off, put a drop in the cup and use a finger to put some on the contact surfaces. Redo it after a wet ride or when the squeak returns… this reminds me, i need to do mine again lol

Does anyone know if the torque boards dual motor mount kit with 90mm / 83mm wheels (Dual Motor Mechanical Kit – DIY Electric Skateboard), fits on the loaded omakase deck?

They’d most likely have to be rear-mounted, but otherwise I don’t see why not.

But you have them mounted inwards on your omakase build.

and the boardnamics motor mounts that you are using are longer than the torque boards ones.

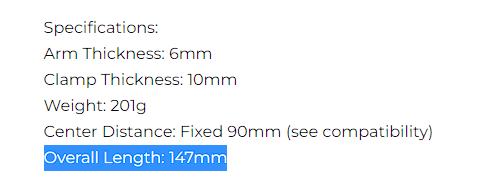

Boardnamics:

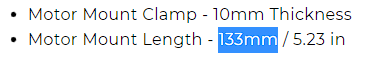

Torque Boards:

or is 133mm the length from the truck axle to the motor shaft?

I am confused and I don’t get why manufactures aren’t more specific with the product descriptions.

I did not use the longer Boardnamics mounts, I used the short mounts with a (IIRC) 55-65mm C2C distance.

Edit: The BN short mounts are 131mm long, so it looks like the TB ones aren’t a whole lot longer. I had to radius the corners of my mounts to allow for decent deck clearance, and I was running 20mm risers.

Ah okay

Thanks for the help!

trust me, they are already doing a better job than 3 years ago ![]()

back in the days, u don’t even see any numbers on the product page unless its for pulley t count

so as not to derail that discussion I thought I’d as my question here.

you’d see a 18s3p as a better option than a 14s4p? The eboosted enclosure I have winging it’s way towards me says it’s good for a 14s4p

I dont know if an 18s config is even doable in one if the controller was externally mounted and/or a riser but I felt that even as a minimum, a 14s4p would be better than the 12s3p that’s in my commuter now

Yeah 18s is better. You can’t do the typical “N” config though with that enclosure. 185mm in not wide enough to fit 9 21700 cells across. You would have to flip the P-groups vertical instead of having them running the length of the board. The cells would be perpendicular to the length of the board, if that makes sense.

That enclosure is 710mm long inside. With 18s3p you would have 27 cells sitting next to each other x 22mm = 594mm. That leaves a little over 100mm for everything else. That’s pretty tight - probably not ideal.

That leaves you with the option to do 6 split p groups (2+1) and 12 normal 3-p groups. That would take up the same amount of space as a 14s4p.

so do you want to hate your life when you build this battery and have more power. If you don’t have any desire to have 18s power, go with the 14s battery, but I know what I would build.

that’s not a thing here is it?

my only concern about going 18s on this deck is that I wont love my other 12s boards anymore… why is it that I’d hate my life going 18s? I would think ‘enhance’ would be a better descriptor ![]()

So ive somehow stripped two of the screw holes on one of my bn drives. I wasnt even using that much pressure, it stripped right as i was getting past hand tight. Pretty frustrsted but oh well. Anyone know if kevin sells just the outer shell by itself? Im also wondering what size the back screws are, as i was never sent any and running without them is causing problems.

For that particular one you might be able to just use a longer screw and let it thread into the other side’s casing a bit. Or use an even longer screw, drill it through and use a nut to hold it together ![]()

Surprised they stripped that easily… I use my electric screwdriver typically and haven’t stripped any yet, knock on wood

Yeah i think im gonna swing by home depot and grab a couple sizes to try

I think it’s an m4 bolt? Get an m5 drill and tap and just tap the threads to the next size up. Ez fix there is plenty of clearance for the bolt head and lots of meat on the bn drive cover.

Edit and with alu threads i use two fingers to tighten them to avoid this, still strip one once in a while but loctite (blue @b264 ![]() ) keeps these types of bolts just fine

) keeps these types of bolts just fine