Solid addition. Potential energy is what it is.

Interesting ponderization

If they’re going to use multiple duros, would it be better to use the orange on the inside wheels or the outside wheels or something else?

- lower durometer on inside wheels

- lower durometer on outside wheels

- doesn’t matter

- matters, but something else not listed here

- same duro all around (for reasons other than appearance)

0 voters

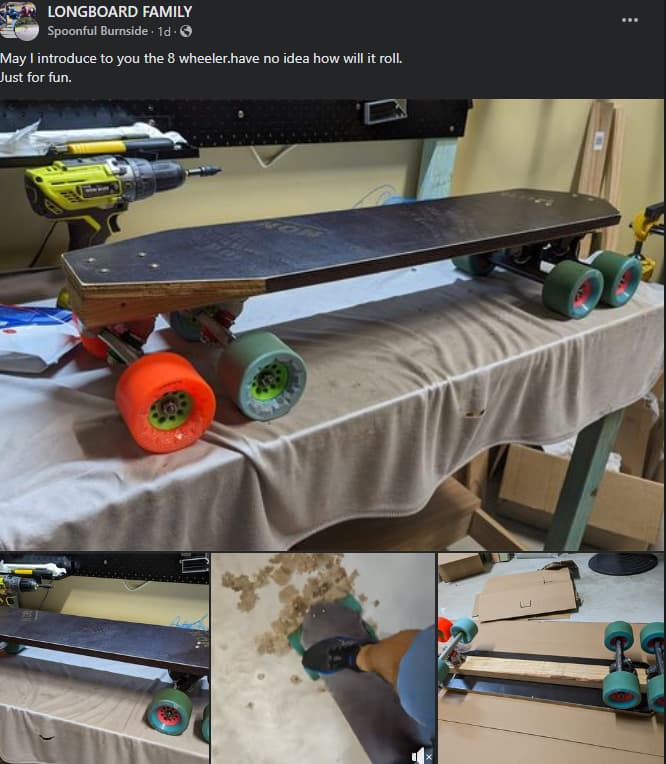

Its a stick axle, so no camber most of the time, except some deflection or damage.

Outside of the wheel does most of the work during hard cornering…can check this with temp and wear patterns.

Are you concerned with performance or wear?

I am thinking for performace, soft on the outer side. Even wear put it on the inner surface.

Next Pooh I will think more.

Interesting take, I was thinking about deck flex as well. Although that deck is unlikely to flex much.

Its still two wheels on an axle, until you lift a wheel. Thinking about hollow wheels is interesting…infinite softness at the outside, till maybe the outside of the wheel touches the ground. Might have to put the grease pencil on the wheel and see how much really gets used…put a few lings and check where it gets rubbed off.

I don’t think it would make any difference since eventually all the wheels on one side will end up hitting/ going over the same surface anyway.

Disclaimer: The only reason I care about durometer is for ride smoothness though as I have no problems with loosing traction as in I am used to dealing with that happening due to riding in the rain and ice a ton when I first got my board. It does and can still happen to me

It is a bad idea overall though since you’d be adding more rolling resistance and it would be harder to keep it going on your own

this is esk8.news, not sk8.news

![]()

I don’t see any motors on the board though? ![]()

#4 reminds me of that old ELF car in F1 that used no springs in its suspension, just interconnected hydraulics

I want to stuff a 12s4p molicel pack with esc’s in a tiny, tiny enclosure.

I’m concerned with esc cooling. PC builders, how malleable are chuncky copper heat pipes? I don’t want to cut a big hole for old timey heat sinks, I’m confident in the thermal capacity of these pipes, but they need bending.

YouTube says I can whale on them, but they were 10$ each and I’d rather not split one open and let out the phase change magic goo out in one sitting.

No problemo. Don’t run high current.

Or do you mean you also want to stuff a 12S4S [P42A?] pack with ESCs in a tiny, tiny enclosure and run high current levels?

Pixies are going to run, it will be warm. I’m confident the pipes will transfer heat at the rates I want. It’s a lunch box setup, will connect to chonk aluminum fins on outside.

I need two 90 deg bends out of that pipe. It’s a pipe, not a straight copper dowel. And it’s unidirectional.

I’m not doing this to @Skunk, but to the twin sister pack. It’s high goddamn time we fucked with thermal problems like adults.

Or angsty tweens.

Don’t go fast.

Those are not the same. You can go really fast on lower current levels.

@b264 you’re trying to go about this as an exercise of meeting the end use targets as rationally as possible, which is incorrect. The objective here is to meet the targets as flamboyantly as possible.

True, but I’m doing basic 12s and pulling a pack rated current for burst.

I think Esc’s at tail of board and separated from battery by a foot or two is less efficient than a good cooling strategy snugged up tight to the battery.

I want to know how rough I can be with the heat pipes.

Whats happened lol. Ill go read