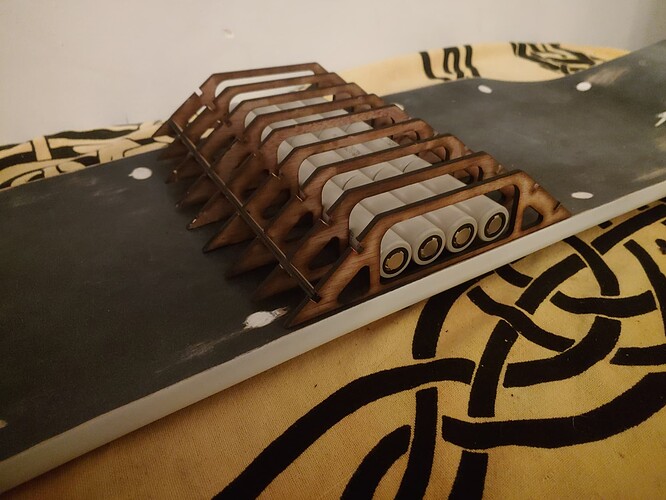

Work in progress,

It looks higher than what I though, when I’ll get the battery done I need some more optimisation

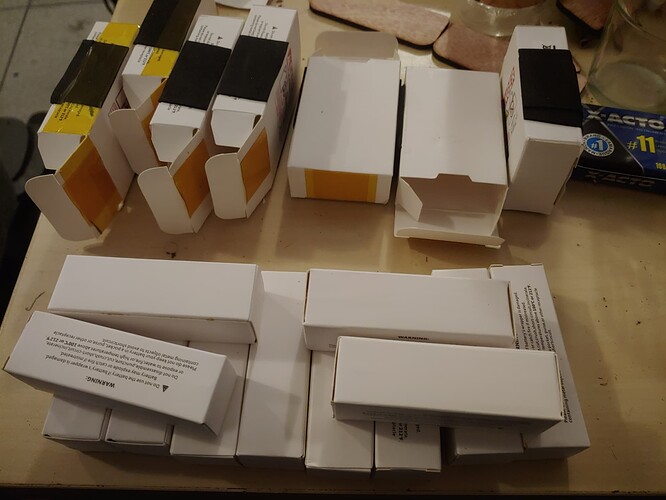

Guys look at this poor soul, settling for mere P42As.

1 like = 1 prayer

I hope they are not fake at least ^^" got them from a local guy

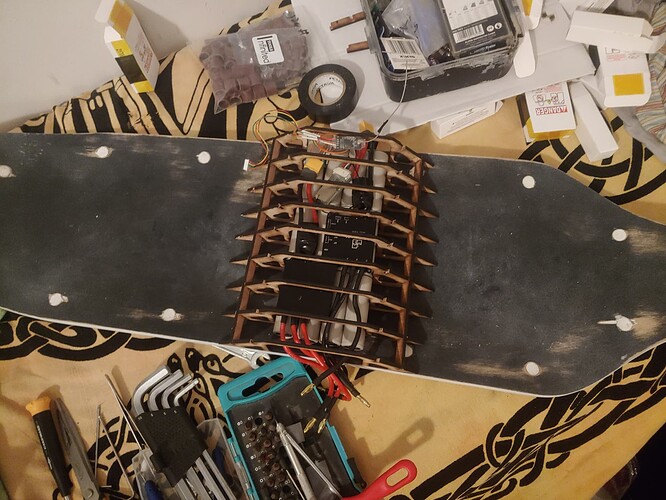

I finaly desasemble my old tayto build and retreived the makerx vtxs receiver and logger,

It all fits and there should be enough place for the BMS too, but it’s going to be a tight build.

I’ve made a couple big hotwire bows with this stuff, use nothing else. The combo of resistivity and tensile strength at high temperature is awesome.

It’s also really easy to make an adjustable tension bow using only materials from a home improvement store. Mine are handheld instead of bench-mounted, but the same principle should still apply.

Oh, that’s cool, could I buy a metre or two from you ? I guess it could fit in a regular mail.

Their website says the won’t ship international if less than 25m ^^"

I have to check if I can ship international from the US, but sure. I have extra 28.5 guage.

DM sent.

It’s been so long I haven’t been ridding an electric board, and this build is sitting there for too long already not going on…

How shamefull is it if I use a simple top mounted case and not go on with the wooden design ?

Not shameful at all. Do whatever you need to get riding!

Perfectly fine to test that the other components work and that you’re even happy with how the board rides + the range you get ![]() Go for it!

Go for it!

You can finish the box next winter ![]()

Meat is back to the menu boys,

The battery is almost done,

I’ve found a case that has almost the perfect dimension

It also fits my og unity so I guess I’ll use this for now until I can make the smaller wooden enclosure I wanted

(The antisink plates are wooden mokup ones, I’ll get the delrin ones done at some point)

Batterie is finished and working

The lite bms seems to get hot ?

I unplugged it from now, maybe it was just trying to balance but I’m taking no risk until I have time to supervise it.

I soldered usable connectors on two ebike cables, everything seems fine the unity detcts them and has no problem with the sensors, the board rolls pretty good,

I need to fidle a bit with the amp settings, never realy used hubs before.

The case fits everything, I’ll make a few holes for the power button and the motors cables when I sure this is the best case, i’ve one that should be better on its way from aliexpress.

It’s time to slap some griptape and to fix the case and the cables.

For the case I’ll use some heavy duty velcro

For the cables I’ve printed to guides, I’ll fix them down after I’ve put the griptape I think, that’s the cleaner way.

Alternatively I could put them under the griptape, this way they would hold better, but it wouls be somehow less easy to remove or change (and less esthetic)

bad news :

- it will probably be raining for the whole week, so won’t be trying it soon

- when I dusted my old flipsky vx2 to use it, I heard something fell,

Funny,

That was the hall sensor

Thought it was the perfect oportunity to try myself at smd

I managed to solder it back in place,

I’ve melted the plastic that holds the joggwheel with the hot gun… So no more vx2.

By chance I had an old vx1 laying arround.

I liked to have the telemetry on the remote, are there potato remote usable now ? Is there anything new on the market that I won’t need to sell a kidney to get and would work better for me ?

So my lite BMS seems to have taken the same path as the vx2 remote, I can’t see any problem but it just doesn’t work and get quickly hot…

By chance I had an LLT BMS (the smart ones) on my old tayto build, it took me a while to get it back to 12s because there was some weird connections on it (I used it with 10s on the old build, so I had to remembre what was the changes and revert them)

Charges and balances like a charm.

The 3D printed cable fixations works well, at the end I putted them under the griptape so it won’t fall or get loose.

Since I was printing stuff I did print the antisink plate in white PLA+ (yeah it’s a small detail but it became an obsession)

The only griptape I found in the right size at my local skate shop is coarse as hell, it was a pain to get trim it to the deck contour. Gosh I hate doing that.

The whole board looks like it is mostly finished, save for the box that I hope to improve (I ordered waterproof gromets and stuff)

It’s still raining outside so I won’t have a chance to try it before saturday night… It goes zoom zoom and reverse without an issue in my 30m2 apt pretty well tho.

Haha that’s usually my favourite part cos it generally means the build is finished ![]()

How did you fix those cable guides to the side before you put the griptape over them?

Looking clean, I dig it!

I made them so they hold in place by themselves,

Then I hadded 3m double sided tape on the groove on both sides

When that was holding well I hadded the griptape over.

I hope it’s enough, I’m still a bit worried though, maybe I should epoxy it or something, but I wanted all of the build to be easily reversable,

I’m convinced that what killed my previous board was laziness motivated by the fact it was a pain in the ass to open and close it for maintenance, so this one is all about soft mounting and accessible hardware.