Cheers dude. They’re LR2170LA cells. Will test some different probe angles at 40j and if consistent and all gd will roll w something like that energy level

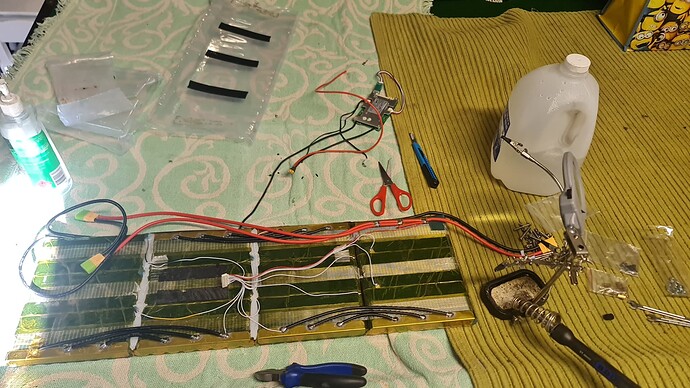

Couldn’t sell my old 12s8p p42a so breaking it down into two 12s4p packs. One for the famous Frankendick by @glyphiks and hopefully i can sell the other pack ![]()

Not quite as simple as I thought it would be to break down. A stanley knife ended up being my tool of choice to split the 8p groups in half but I still shaved the edges of a few cells causing a few little sparks ![]() . They’re still all testing same voltage so hopefully all ok. Ill build my pack with the cells i sparked just in case.

. They’re still all testing same voltage so hopefully all ok. Ill build my pack with the cells i sparked just in case.

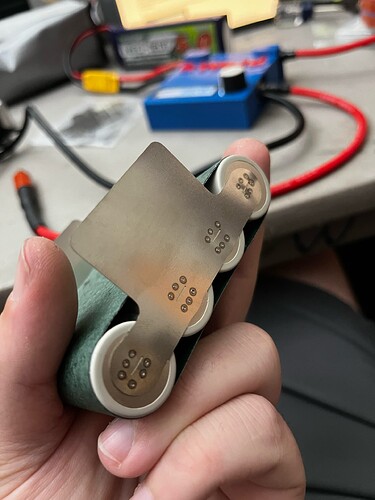

What’s the purpose of the additional nickel squares on top of each cell terminal?

I thought they were indents? But ya, they look clean but whats the purpose here?

The main plates are made of nickel-plated copper, by itself it is very poorly welded and holds, welding in 2 layers of iron + copper gives very good strength, copper itself does not hold well and is very soft

@iliamaslennikov9 It depends, most spotwelders like the kWeld even, are stock/out of the box indeed not strong enough to spotweld copper directly, nickel will help it to generate enough heat for it to actually stick

there are only a few that can really do it reliably like the sunstone pa250i but thats a very expensive spotwelder and only okay priced for companies that might be building packs regularly

There’s a lot of development of the nickel (or steel) and copper sandwich on endless-sphere. There’s also been companies in China that make custom copper/nickel hybrid strips that are ready to go and easier to work with

I found my cheapo welder/lipo combo did not have the power to weld 0.15mm copper with 0.15 pure nickel atop, nor 0.15 copper with 0.10 nickel plated steel atop, but it does have enough power to weld 0.1mm nickel plated steel atop 0.1mm copper.

Using the infinite slot method, on recovered cells whose nickel plating was mostly sanded off, I did achieve success with 0.15mm copper and 0.1 nickel plated steel, but when I tried that combo on new cells with fresh nickel plating, about 50% of the welds were inadequate, and peeled off way too easily.

I doubt my low power requirements really benefit from the lower resistance series and parallel connections, but warm and fuzzies can be priceless.

That’s a clean looking battery, but it appears the very center of the cans was not deliberately avoided.

I didn’t have good results with my attempts to do the sandwich either and ended up getting the pre-done custom stuff from China. It’s super easy to weld.

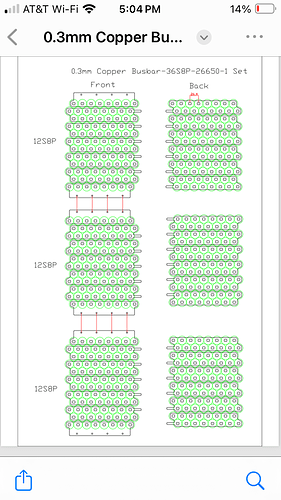

I’ve got these extra strips for a 36s8p 26650 battery I ended up not making I’d sell for 50$ including shipping. You could cut them.

.3mm copper

They’re super cool. Does anyone make similar for 21700 cells?

Something along these lines?

https://www.aliexpress.us/item/3256805451764272.html?gatewayAdapt=glo2usa4itemAdapt

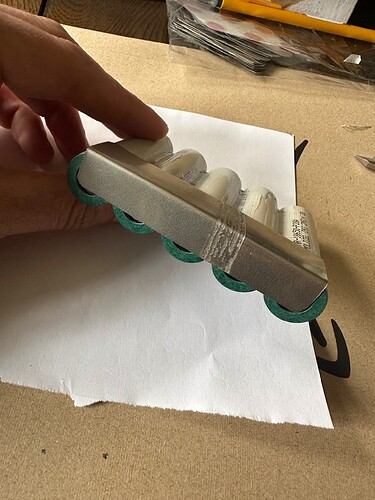

While my first attempt at copper nickel sandwich failed, I ultimately succeeded, well so far anyway, I have about 300miles on the battery so far, my first.

The copper sheet has an oily coating which needs to be removed, and one should use gloves when handling it after cleaning. A white napkin soaked with 91% isopropyl turns a greenish black hue when wiped across what appears to be clean shiny pristine copper.

I hypothesize that 800 grit well worn wet sandpaper scratches on both sides of cleaned copper also increase the resistance during the weld reducing the pulse duration\joules needed to achieve a proper weld.

The cap atop the copper need not be thick nickel, or even pure nickel. My cheap welder came with 0.1 nickel plated steel, which I used up, then ordered more nickel plated steel, and was glad to see it fail the rust test. Imagine ordering plated and getting pure nickel.

What is weird, is that after peeling off sandwiched welds on the test cell, is that the copper dots left on the cell take a lot more effort to flush cut and sand off, than 0.15 pure nickel does.

I was using doubled paper sanding disks on the dremel’s cut off wheel arbor. Nice and flexible and forgiving.

I am far from being an experienced battery builder…

Ive learned so much from this forum, I’d like to share my limited experience with the

copper nickel sandwich, hoping it might assist others.

They’ll do whatever u want and quickly. There’s at least two places you can find on alibaba. I just ordered a 33s9p set for 21700. Those robot battery cells

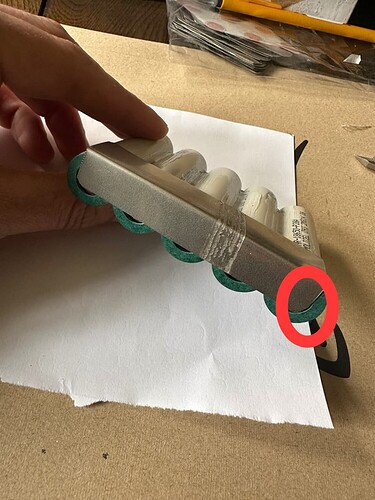

Little hot, turn the welder down a few joules.

thanks. feedback transmitted.

Hi, Friend here. Message received ![]()

Anybody got a link for 18650 5p nickel plate so I preferably don’t have to cut my own? Thx