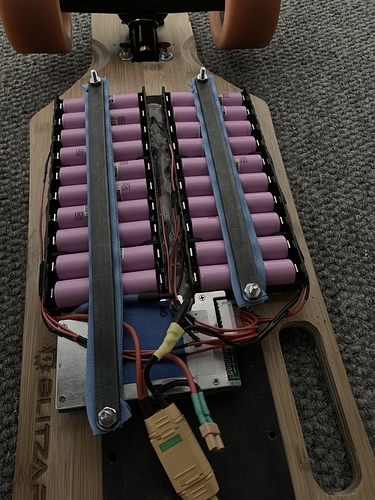

What do we think about this assembly style? ABS cell holders, 10 awg current carriers, cell > steel > solder > copper joints

Pros:

- Minimal risk of bridging p-packs

- shields underside of battery

- flexible (only when enclosure mounted)

- hella cheap ($20 for 10s4p) (only requires soldering iron)

- replaceable cells

- tested up to 10A

Cons:

- unknown amp capacity (tabs limit to maybe 20ish)

- 37% larger footprint over cells (no wires)

- only single stack

Notes:

- holders can be cut to make a smaller holder

- optimal configurations are 8s and 12s (6s, 7s, and 10s have leads come out an outer corner)

- use 4 slot holders (less cost and footprint per cell)

Procedure:

- buy holders, 10 awg, 22 awg, solder on eBay for $20ish

- wait 2 weeks for shipping

- fold the pins away

- tape holders for convenience

- make an XT90 pigtail (it’s the perfect width for the middle)

- strip sections of the 10 awg to match the tabs

- solder 10 awg to the top of the tabs (heavily tin both sides)*

- add more solder because it never hurts

- all the typical balance lead stuff

- insert your cells of choice

- shrink wrap the whole thing (190mm wide)

- drop it into your enclosure

*Work with the frame sideways so gravity doesn’t pull the solder over the contacts (it’s already a super tight fit)

These are my two battery packs made in this style (10s2p and 12s4p)