I did, I contacted you over a month ago and I sent some reminders in the meantime, latest was yesterday. ![]()

I just realize the email was in junk mail. I already responded with the quote.

Ok, review of the double pulse im getting from the p60f: using the brazing flux and welding .3mm copper to rs50 cells at gear 400 preheat @.3ms intermittent @.2ms. Continuous welds set to 1 in manual mode.

Is the sub settings interval time of continuous spot welds set to 2.0 seconds

Using the original foot pedal i would get a double pulse about every 20-40 welds. I tried various different methods of activating the pedal to try and avoid it but couldn’t isolate the issue to how i was operating it. Even tried barefoot just to really feel the switch actuate and continued to get the double pulse intermittently

I replaced the pedal with the one from my kweld which had a better micro switch but essentially the same pedal and kept getting the same number of double welds. Intermittent but about every 20-30 welds. @DIY500AMP.COM sent a new pedal (thank you ![]() ) but the issue doesn’t seem to be with the pedal itself. Because the copper is such a good conductor of heat it hasn’t really been an issue.

) but the issue doesn’t seem to be with the pedal itself. Because the copper is such a good conductor of heat it hasn’t really been an issue.

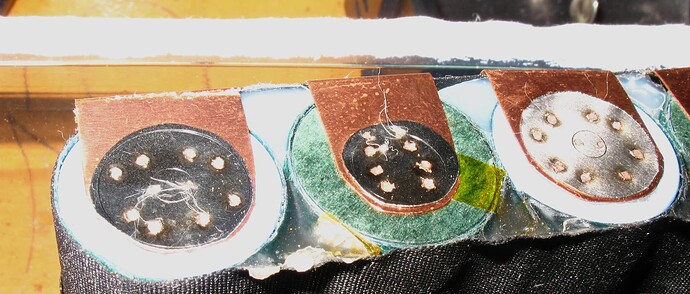

I increased the size of the copper im using so that i get more overhang on the edge cells and keep my welds about 2mm from the outside edges. When welding a single pulse has good attachment even when very close to the edges but a double pulse can burn through, with a little more clearance the double weld is nearly indistinguishable from a single pulse. There are two sets of welds in the picture and visually it is impossible for me to distinguish them with marking.

Did a tear off on a dead cell and the double pulse isa little stiffer to remove but doesn’t seem too far off from a single

The unintended double pulse is dismaying.

If there is a double pulse happening in your videos, I missed it.

It looks like your lead’s bullets can be seated a little deeper into the unit’s receptacles. I know Nelvick has had issues with them working their way out when the leads jump repeatedly.

I have noticed this too, but have only built small batteries and am not doing many welds successively, but have found when using a high gear when the cables really jump that I can push them back in a mm, sometimes.

Do you think it is possible there is some inductance going on with the cables being physically near parallel for a short distance with the wire for the pedal, and causing the occasional unintentional double pulse?

Maybe the plug for the pedal should be 90 degrees, or it needs to be shielded.

I do have my pedal cable take a hard right turn out of the machine, but more so to be out of the way, rather than fear of an inductive second strike, if that is even possible. Maybe a snap on ferrite ring?

I have at least another 100 welds without an additional unintended second strike, but I set my P20B to a double pulse.

I have had only the one surprise second pulse in all my batteries, but my foot could have still been half on the pedal.

I would fear that welding atop the purple Sharpie marker between copper and electrode tip would introduce contamination and potentially inconsistency. I know the preheating pulse is supposed to take care of that.

My old welder was so temperamental I had to wipe both sides of sandwich strips and cell free of any fingerprints or ‘other’ just to approach something consistent.

I have been scratching a ring with a sharp awl, for excluding the 6mm center weld spiral of EVE 40PL, and to confine welds within the 10MM circle on positive tab. I find it really helps positioning the strip on the cell, as my ability to tin snip perfect circles is lacking.

My previous esk8 batteries with 0.1mm copper I would bring the 0.1 nickel plated steel up over the shoulder and tack spot weld the stainless to copper before welding proper to the cell, but this is 0.2mm copper and is not so flimsy.

This pack I decided to not weld across the spiral/ center and tried to keep electrode distance the same, and 4 pairs of welds on the Anode, 3 on the cathode were what eventuated.

The two welds in the center spiral are just the gear 002 tack welds to tack weld ss to copper off the cell, same as the two at the top of the cathode weld. Sorry for the cotton Qtip fibers, I dont notice them with naked eye.

This flexible 10s1P pack, the gaps between each fishpapered cell is filled with silicone, two different types, one much more clear than the other. I figure it is far better than dead air space for transferring heat from cell.

It’s the last weld of each video

Watch the leads carefully, you’ll see the double jump.

Speaking of double jumps…

Ok, can see the leads jump twice.

My Single instance of unintentional double pulse was much more separated than that, leading me to believe it was my foot rocking the switch.

The closest one can set the double or triple weld pulses to each other is in 0.1 second increments, and the pulses in pecos’ video looks to be well below 0.1 second

last set of welds in each is a double yup. It’s not as clear in the video as it is in the hand. You can hear the distinct double beep irl better than in the video also.

Im not noticing any difference between welds made on the sharpie mark vs off - and the preheat seems to cook the mark off in the area of the weld as well. I don’t think it’s creating any issues, definitely weld strength seems fine.

Is it possible the proximity of the cable for the pedal being close to the welding electrodes can cause the double pulse?

Ya it’s way faster than the double and triple pulse i was experimenting with at first. It’s odd, i moved my pedal lead off to the side and ill try some more welds later and see if it helps. Though the work around is ok the inconsistency is unnerving. Im being super careful about my placement and keeping a solid grip way longer per weld just to be sure i dont get an accidental misplaced weld on the second pulse if it happens.

I know to not trust A Eye responses, but this seems plausible.

quote:

Yes, it is possible for electromagnetic interference (EMI) or a phenomenon known as “inductive kickback” from the high-current spot welder cables to cause a false trigger or a second pulse in the foot pedal control circuit.

The high-current pulse in the welding cables creates a strong, rapidly changing magnetic field.

If the foot pedal cable (which typically carries a low-voltage, low-current logic signal) is run parallel to or coiled near the main welding leads, the magnetic field can induce a spurious voltage spike in the foot pedal cable. This induced voltage can be misinterpreted by the welder’s control circuitry as a second pedal press or an activation signal.

How to Prevent This Interference:

Separate the Cables: The most effective solution is to keep the high-current welding cables and the low-voltage foot pedal control cable physically separated as much as possible. Do not route them in parallel or bundle them together.

Twist the Pedal Wires: Twist the two wires of the foot pedal cable together. This helps cancel out electromagnetically induced noise (common-mode rejection).

Use Shielded Cable: Use a shielded cable for the foot pedal connection, and ensure the shield is properly grounded at the control circuit end to shunt induced noise to ground.

Minimize Loop Area: For the main welding cables, minimize the loop area between the positive and negative leads by running them parallel and taping or zip-tying them together (except near the electrodes). This reduces the overall inductance and the strength of the magnetic field they produce.

Add an RC Snubber/Filter: The control circuit input for the foot pedal might benefit from an RC (resistor-capacitor) snubber or filter circuit to absorb transient voltage spikes caused by the interference.

Check Welder Settings: Ensure the welder’s controller has an “anti-false trigger” function enabled or is set to a mode that prevents overly rapid re-triggering (some have a built-in delay between potential triggers).

Proper cable management and shielding are essential for reliable operation of sensitive electronics in high-power environments like spot welding.

Well the “interval time of continuous spot welding “ is not the false signal protection or it doesn’t work. The original cable is not shielded and isn’t twisted and the port on the machine is pretty close to the welding lead connections. I’ll play around with it and see if i can’t get better results

Yep, seems that it is not a great design to have the pedal port so close to the electrode ports on a machine so powerful it can weld 0.3mm copper, no sandwich, at less than half its available power.

A shielded pedal twisted wire should also seem to be mandatory.

I’ll be routing my footpedal cable even further away and taking into consideration the loop distance, as I don’t wish to experience the unnerving unexpected pulse.

Let me ask the engineer what they think about this unusual behavior. If you keep both cables together using a rubber band, in the beginning this helps with the kickback voltage.

That would help with RFI but wouldn’t stop any magnetic fields (which could potentially cause current flow in a wire).

But as @DIY500AMP.COM mentioned, keeping the main leads close together could potentially help as it helps the magentic fields in the two wires cancel each other out and lowers the wire’s inductance which lowers the voltage spike created every time the current flow for a pulse stops.

Tried to route the cables as far from the pedal wire as possible and still got some double hits from it. I’ll throw a couple rubber bands on the weld leads for the next go round and see if that reduces it at all. Ill be assembling an 18s3p next with more of the rs50s and doing some experiments with that ss sandwich for series connections with all that scrap sheet @DIY500AMP.COM sent with my last order to get some cycles on it and see what effect it has

Just messing around, copper to copper can weld pretty well with the magic paste, seems to take a bit more to get a sandwich connection consistent but the mated surfaces are obviously cleaner. Even putting 8 rapid consecutive welds the sheet is warm but not hot to the touch.

With the experimental welding, perhaps put it on automatic, and see if double fires still happen.

AWithZ engineers said that when using preheat, it fired twice. That’s not a convincing explanation, and I told them so because it has never happened to me. I’m waiting for a better explanation or solution than disabling pre-heat.

Ya, that doesn’t seem to add up. If every weld had the same double beep and pulse i could see this being the case but that doesn’t seem to be what’s going on. Ill mess with the preheat setting and see what that does but the intermittent nature of the behavior is why it’s so difficult. I may open the welder up and see if maybe it’s a bad component or connection. I wonder if it’s just a partial failure of something and maybe snuck past qc from the factory