Did some searching online and couldn’t find anyone else complaining about this type of behavior but it is a newer product so not necessarily a good indicator

I’d be interested to see inside too, but they have a 1 year warranty don’t they?

I didn’t see an easy way to look inside my p20b without a prying tool.

Seems something was lost in translation with that preheating response.

Does the double hit happen every 20 to thirty welds, only after getting hot from doing 20-30 welds at gear 400. Does it do it when cold?

They do have 1 year warranty. If that is a show stopper can be sent to factory for fix/exchange. I can help with the proces.

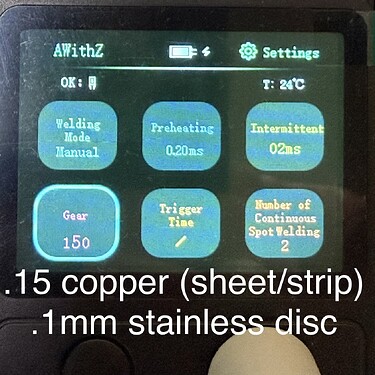

WOW. This thread is gold. As I settle into my regret with purchasing an AWithZ P30C, I assumed my issues were simply due to this being very new to me, overall. But others seem just as confused as me. When trying combinations of stainless|nickel|nickel-stainless with just .15mm copper, I’ve been chasing my tail on excessive sparks, one super solid weld and one crappy weld, and rapid fire welds (see below). Thinking I lost the manual but realizing nobody seems to really know what the settings do without significant research, and even then being unsure, make me feel much better (in that maybe I’m not simply an idiot). Fortunately, I have/had a mountain of dead cells to practice with.

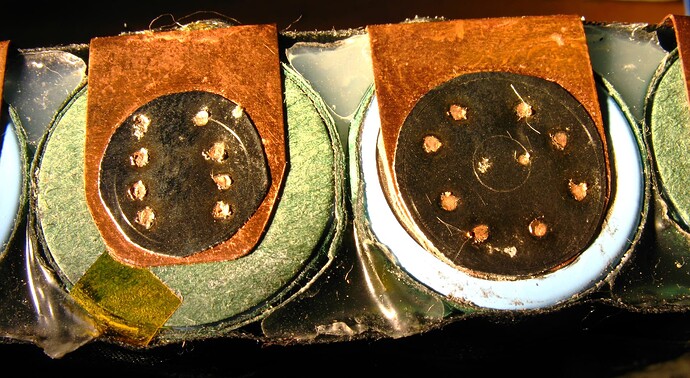

I’ve similarly had a really hard time seeing differences with the preheat / intermittent setting. I’m getting what I consider good (bonding) results with .1mm stainless + .15mm copper. These were with Gear 150 / .2 preheat / 2ms intermittent / 2 pulses (#1). But I think I’ve changed things up quite a bit with Gear 230 / zero preheat / single pulse (#2).

This screenshot below of a few cell are on new cells with #1 settings. I’m very inexperienced - but everything tears like crazy after peeling, I’m just getting a lot of oxidation on the tips and a fair amount of sparking (and that splatter). The second set of settings seem to help but the optimization routine is super tricky as it seems like others have seen. I’m just having a hard time getting two super solid welds without a bit of splatter as below. I can try and upload welds on option #2 above if people are interested.

RAPID FIRE: I’m using the pedal and will say that I spent quite a bit of time trying to figure out why a single press could trigger infinite welds at rapid succession. Like 8 in row - seemingly forever until I lift my foot. I had taken to simply tapping as quickly as possible on pedal (which is tiresome). I’m glad to see this seems like an error of some kind. I don’t know if because I’m using lower power or no preheat, but I swear that issue has mitigated a bit and I don’t have to tap the pedal lighting fast to just get one weld - and I did test at gear 001 and can’t reproduce this infinite loop.

[edit: apparently I can’t embed media or links directly].

Not trying to actively spam this thread, just trying to post an image as I had mentioned above. I guess at my trust level I can’t edit posts, post hyperlinks, or images of any amount. Seems to not agree with the trust level descriptions, so here is a lame-O not link. ![]()

imgur[.com]/UL2LSdQ

Welcome to the forum.

You got to do some reading and stuff before being granted more posting privileges.

Sorry to hear of another rapid fire event with AwithZ’s. I only have ever once, potentially, had a secondary unexpected firing. I always use the pedal, and never considered the duration at which I hold the pedal.

Shooting sparks is pretty normal on any welder, so trying to eliminate that occurrence is unlikely. The amount of sparks seems pretty variable and I believe the Stainless or Nickel plated steel itself plays a role, as does the pressure used, and the size and shape and cleanliness of the tips.

The shape of the tips that one files in and the pressure used are huge variables that are difficult to compare between users, so What settings I use with my P20b can be far different than another user with a different grade of stainless or purity of copper.

The little red file which comes with the AwithZ’s is pretty aggressive. perhaps the deep grooves it leaves on a microscopic level is also responsible for inconsistency and excessive wear on thew tips.

I really try and file them both to the same size and shape, using strong light and magnification, and I have shaped many a surfboard and fin and have an eyeball for that sort of thing, and as the electrodes wear they get thicker and thicker, and can develop that lip at the very edge, and that seems to really increase the shooting sparks, So I like to see if I can feel that lip/ ridge and make sure it is gone.

I might glue some 600 grit sandpaper to some glass as the file itself seems to be around 120 grit.

If one does punch through the copper into the cell, some steel will stick to the tips and is really hard to file off, and having that stuck to the tips really screws with subsequent welds.

As far as the multiple strikes goes, I have not had it happen but perhaps the one time.

I was theorizing that EMI on the pedal cable from teh welding probes was potentially a cause but Pecos said he routed his pedal cable as far away as possible and it still occurs.

So it seems the multiple unexpected pulse thing is an issue on at least two of the AwithZ welders.

Do note that if test welding on used cells that had previously been welded to, that the settings will be different than on a new cell. The steel is annealed in the area of previous welds, and when the material is resting on some dots from previous welds, it also changes the resistance. If the previous material is sanded off then part of, and perhaps all of, the nickel coating on the steel can is removed increasing resistance, making for a hotter weld for the same settings.

There is also difference in the settings required on different new cells. I think this is due to different thicknesses of metal plating, and the surface texture there of.

So really when building a battery, one needs to at least test the settings, and do tear off tests, on the actual cell model that they are building the battery with.

One other trick for increasing consistency is cleaning the strips and cell before welding. I use rubbing alcohol and one can often see a Qtip turn dark when scrubbing the copper or stainless or cell can itself. The copper itself might have some oily type coating to prevent oxidation. The preheating pulse is supposed to take care of this, but I view it as only a potential partial mitigation of contamination.

Excellent tips! Thank you. I, too, was thinking the included file was super aggressive but haven’t experimented with finer grits yet, but plan on doing that. And re: sparks, IIRC, I mostly get sparks when stainless is involved but the data was a little muddied there since introducing stainless drops the power requirement so much.

I have not found the sparks to be consistently greater or lesser with SS vs NPS vs pure nickel, but have largely written off pure Nickel by itself, or nickel plated steel in a sandwich.

I do notice I can almost Aim the sparks, depending on tip shape and the angle I hold them to the cell/strip.

There is also times when it seems the same exact combo shoots way more sparks than another time using the same sandwich and same settings on another day. and I am largely in a pretty well climate controlled area at the moment. Ambient humidity and temperature are largely within 10% and 3 degrees F on all my welds.

My theory on the inconsistency of sparks generated while trying to eliminate as many other variables as possible, is blaming the homogenous nature, or lack there of of the stainless steel alloy.

Strangely my 0.5MM stainless steel, which is some type of 400 grade, was largely devoid of sparks if I remember correctly, and I was using super high settings.

With my old welder, I was using an Arkansas sharpening stone which is super fine grit to clean and shape the electrode tips which I made from pure copper. The Awithz tips are some sort of harder copper alloy.

I need to try that again with these electrodes as it is quick and easy and likely allows me to shape the conical tip in a more precise manner.

Watching videos of other people using the electrodes, they tend to hold the welding pens at 45 degrees, so that a potentially sharp corner of the electrode tip is pressing the strips to the cell. This has to be far different than the welding tip being rounded with a slight flat spot and the electrodes held nearly perpindicular to the strips.

I try and hold my electrodes as near to vertical as their width allows, as I feel this allow me to have more equal pressure on both. The AwithZ welding pins have the finger flats so I also try and use these in a consistent manner as well, and file the tip so that there is a small flat spot and a more equally rounded edge when held nearly vertical, in the same hand, rotated the same way.

Glad you joined the forum and chimed in with your experience.

Look forward to your ability to attach pictures in the near future.

Basic level achieved! Here’s a pic of those welds I was mentioning above:

.1mm stainless | .15mm copper | P30C at settings shown.

How u get the slits in the ss?

I have not yet tried to weld across a Slit. Mostly as making an imprecise slit with a dremel already makes a tedious process more so.

The slit should be more effective ( in allowing lesser power levels to achieve the same weld) if the Slit was in the copper too.

I read a white paper saying that the Slit decreases the size of the spot weld, but they were using tungsten electrodes and it was not so much a slit but a 2 pronged fork and reducing the length of the fork’s tines made for a wider weld.

Looks like a lot of the SS ejecta, is almost parallel with the SS striations. Try maybe less duration of preheating?

I have gotten that same amount of ejecta when using a bit more power than actually needed, but all my succesful welds, when cleaned with a q-tip and rubbing alcohol will catch some cotton fibers, even if I try and press them down with a rounded tool and pressure.

If the tear off strength of your welds is acceptable, then I’d say you are pretty close to the ideal settings, at least on those cells with that material thickeness.

I believe they’re cut with a fiber laser, but @DIY500AMP.COM cut them for me as a custom job - but I feel like there’s got to be a market for having some non-custom options. I saw a video he posted with these SS discs with slits and was like “TAKE MY MONEY".

Thank you very much for the feedback! This is actually where my settings were going:

Gear 230 | Zero Preheat | 1 Pulse (for the same material combination). Still need to test some though. I’ll try and post some test welds sometime with the final settings. I do think I need to clean these discs though. Fair amount of burn from the cutting process that I really should address.

Here are some of my latest welds when building a 10S1P Eve 40PL

AwithZ P20B 14.6kW

0.2mm copper under 0.1mm stainless steel

Preheating 0.10ms

Intermittent 04ms

Gear 385

Number of continuous spot welds 2

Interval time of continuous spot welding 0.2 second

With Flux.

The cell on the left the two little spot welds up top outside the scribed circle, were just to adhere the SS to the copper before welding the sandwich to the cell. a positioning aid.

Same for the two welds within the small circle on the cell on the left. The scribed circles help greatly when positioning the sandwich on the cell, and on the negative of tabless cells that have the center weld spiral, one needs to avoid welding atop the spiral.

I am not so concerned with minimum size or weight so each cell is individually fishpapered, with an extra layer around the cathode+ shoulder, and I used silicone to fill most of the gaps between cells as silicone is a better thermal conductor than dead air space.

Love this pic, all the info for reference. ![]()

![]() Im going to start doing the same so hopefully helps someone in the future easily find a good starting point to get settings dialed in

Im going to start doing the same so hopefully helps someone in the future easily find a good starting point to get settings dialed in

Eager to see the results.

I too enjoy the simplicity of no preheating and just one pulse, but I think with the preheating and a double pulse one can achieve a stronger wider weld with less heat entering the cell.

it is just proving that the heat , entering cell anyway, is actually less is impossible for me, and also the proving the weld strength and width is not so simple either.

if the single pulse and no preheating is just to combat the unintentional multiple fires, well I am dismayed that yours and Pecos’ welders are doing this. I was really hoping that moving the pedal’s cable as far away as possible from welding cables would sort it out.

There has to be something going on with the microcontroller or something. I keep trying different arrangements and settings but only the auto mode seems to be 100% reliable. It’s just slower and less consistent for me to make that change to my process/preference.

As far as double pulse, I noticed that the welds seemed to be ever so slightly more symmetrical in the pull off tests, especially on old recycled cells.

going through my recycling pileto try a bunch of different settings to eliminate the double pulseAs far as heat distribution and dissipation into the cells, anecdotally I noticed that the weld is touchable much faster with copper than with nickel. I don’t have any perfect comparison because i am using.3 copper and .2 nickel as my standard material thickness but i have touched recently welded nickel and have to pull my hand away quickly to avoid a burn but can press and hold a copper weld with significant pressure after a couple seconds. I think that the copper wicks the heat away into itself much quicker because it is such a better conductor and therefore should quickly bring the temperature of the weld down and distribute the heat throughout the copper preventing more heat input into the cells.

I don’t think either are a significant impact on the cells nor are they avoidable with this form factor of cell but it’s nice to see it isn’t worse in than nickel welds.

Going to try welding copper to copper as these cells have copper terminals. I do t know how anyone builds with these other than compression (assuming welding copper to copper needs more power

It is certainly unavoidable. It is just that we are using a lot more power to weld copper to the cells, and I don’t think there is enough people who have used copper, to yet notice a trend of lesser battery longevity when spot welding copper busbars compared to pure nickel.

Is the amount and degree of electrolyte that is exposed to the welding heat significantly different? No idea.

Even if there is more electrolyte oxidized from welding heat, that might be offset as the copper itself keeps the cells from getting as hot in use, acting more as a heat sink than a heat source, compared to pure nickel anyway.

I am just happy that I can weld 0.2mm copper, with only 40% of my welders power, and want to get my grubby paws on 0.25mm and 0.3mm copper and experiment some more.

My old welder requiring 85%+ of its power to weld 0.1mm copper under NPS was kind of stressful, as i thought it was going to smoke a mosfet on every weld.

A little more food for thought:

https://iopscience.iop.org/article/10.1088/1757-899X/1098/6/062097/pdf

“Conclusion

Based on data from the results in this study, it has concluded that in the process of micro resistance spot

welding the current and the distance between the electrodes greatly affect the welding results such as

nuggets, HAZ Area, and shear strength. This is also shown by data obtained from simulation results and

experimental test results. The closer the electrode distance, the higher the weld strength.'“

@DIY500AMP.COM has made some batteries using these specific Lifepo4 cells, and has a video with more information, but I can’t find it to link it here.

Did you get some copper flux/ brazing paste, and perhaps a stronger welder?

IIRC your welder was struggling with one weld much larger than the other on 0.2 copper under stainless.

I have not yet tried copper strip to thick copper welding, other than stacking copper under stainless to achieve thicknesses greater than 0.2mm, or welding copper strip to stranded copper wire, or braid.

Which reminds me I need to make samples and mail them off.