Why? I imagined the heat would increase with greater resistance and with it an increased ability to weld. I guess at some point there’s other variables besides simply resistance.

If you scroll through my posts earlier in the thread, I show lots of pictures and the settings I used to weld the 0.5mm stainless on top of various thicknesses of copper.

My 0.07mm stainless might not be 304 grade. I was surprised it did not allow for me to lower the gear as I expected.

The 0.5mm stainless did seem to make the copper welded below it, very flat. Id like to try 0.2mm and thicker stainless, for that reason, and because I know I have the power.

sanding the copper will reduce the surface area between copper and cell under the electrode, increasing resistance, and heat. Try it.

Can also sharpen the electrodes to try and get a stronger weld with welder on the edge of being powerful enough

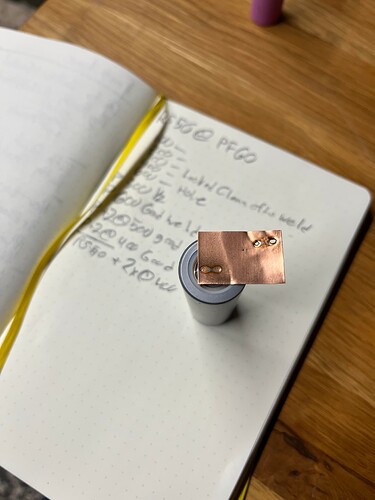

Sorry about the formatting, latest forum update makes posting a pain and the formatting its next to impossible for me to edit or move my cursor without crashing the gui. Tldr isnive got about 3 pages of notes looking for settings to weld .3mm copper to rs50 cells and finally dialed one im satisfied with. Not too hot and good adhesion. P60f welder gear 400 with 2 pulses at 03 interval with .15ms preheat with flux. Nothing else worked well. Single pulse was getting way too hot for my liking even with paste and tripple was the same with no significant decrease in gear (heat input). good strength and tearing tests at this setting and the copper wasn’t too hot to touch or fully heat soaked and could be handled without gloves after a few seconds

Thanks for the report.

If you clean the flux after removing a strip, is the copper tinned?

I find myself guilty of not using the flux on the Non Esk8 batteries I’ve assembled, even though it reduces the gear required with 0.2mm copper, and applying the flux is not nearly as much of a time adder as cutting and positioning sandwich.

I built a 3s4P of Samsung 50E just using 0.2 copper under 0.1mm stainless sandwich and double pulse gear 550 but lowered this to 520 as the welds looked and felt really hot, and these cells were dremelled free of previous welds which always seemed to reduce the power required for subsequent welds on or near the same areas of the cell.

The 7s1P JP30 which went into my vacuum cleaner and the 5s1p Sunpower cells which went into my Ryobi, I went without flux, basically as I know the extra power is there if needed, and it is not a requirement for 0.2mm copper, as there are no consistency issues without it when using stainless sandwich.

I dont feel I have a good grasp on the observable effects of changing preheating duration, the ‘intermittent’ between preheating pulse and first welding pulse, or the Interval between pulses which one needs to go into the Systems settings menu to change from 0.1seconds, all the way upto 5 seconds. I might go back to testing on the trapezoidal thicker razor blades, and just going to the extremes first and working my way towards the middle.

I also found that a single pulse at a given gear seemed to hit way harder than double pulses of the same gear, by the way the cables jumped, and the tear off strength.

There is so many fine tuning variables, and it is hard to quantify the actual results. if it is welded and both welds are the same size, then nothing really needs to change. One could be using far more energy than required to achieve the weld.

it would be nice to quantify the effects of using too much energy on welds, on cell longevity, versus just enough. is it 4%, 15, 25?

Is it worthwhile to use both stainless sandwich AND flux just to use lesser power to achieve the desired weld?

What’s a little extra Oxidized electrolyte gonna do?

Any reports of batteries with very hot welds failing prematurely, with no other variables?

I guess to be on the safe side, sandwich and Flux and the lowest power needed is the safest bet, but a time consuming one.

I feel I got a good handle on 0.2mm copper Stainless sandwich, and my builds certainly don’t require 0.25 or 0.3mm copper.

I do want to try those, when I am not stacking copper to attain that thickness.

Can’t really get to the flux to clean it off but im using it sparingly. I have a little plastic spatula i put it on with just thin enough to leave a smudg

Then letting it sit for a minute to dry, the stuff will dry fairly quickly and get so that it doesn’t move around much

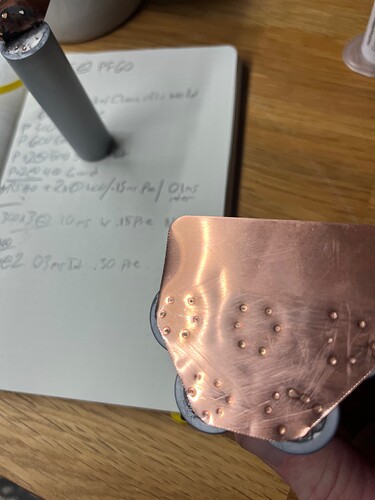

Then im doing the welds and it’s completely covered. Still getting the feel for this but im going to go from .3 to .25 copper in the future because the .3 i found is too hard and i have difficulty burnishing a flat spot to see the cell through the copper as well as i like and my welds aren’t as accurate as i want them. Nothing bad but not 100% perfect yet.

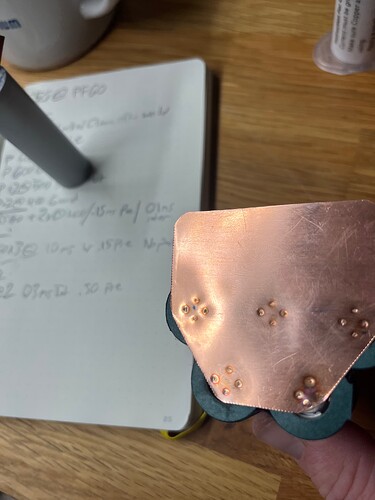

You can see on the negative a couple welds are

placed kinda messy but i checked carefully to make sure non are in the bullseye. I might make a template to go on top to make better center marks if i can’t consistently burnish a center well enough to clean them up

Love the reports from an experienced Esk8 battery builder using 0.3mm copper on a top performing low resistance cell like the Reliance RS50.

Regarding the tinning effect of the flux, I was only referring to inspecting the copper underside on the torn off test welds.

I found the more power was used, the more distance from the weld center the copper was tinned, when torn off, and successful welds could still havee very little tinning occurring. and some welds where more power than required was used the tinning effectively joined together between the welds and a significant distance away.

I was only using the syringe to apply more Flux than needed for my testing.

I have not actually built a battery using the flux.

I have a 10S1P of Eve 40PL fishpapered up and glued together, but have not cut the copper and stainless, and am still thinking about ordering 0.25mm copper, as opposed to stacking 0.15 and 0.10mm.

My previous build using 0.1mm copper, 0.1mm nickel plated steel with my old welder on BAK45D, I was prewelding the steel to the copper, and using strips to avoid the cell center.

My imprecision, despite efforts to achieve precision, I found I was often needing to weld atop the cell heatshrink. I wound up razoring it off so the whole bottom of the cell was exposed.

I wonder if needing to make a template for weld location on larger packs, how much more difficult it would be to make the template out of stainless, and preweld that to the copper.

Ahhh ok, misread that a bit. I didn’t see much tinning beyond the weld itself but i was working front m low setting and adjusting up by about 25 “gears “ each step until i got good adhesion and tear off was symmetrical between the two weld points.

Anyone can do a decent resistance test of the welds? I wonder if 4 is good enough or worth doing 8 or something.

maybe welds that seem not so solid are still giving good conductivity

The precision needed to measure this is high. I’ve never tried the 3-wire method but if don’t hear of anyone testing I guess I’ll try that

This thread touched on the testing of weld and welded strip ampacity, and one of the stumbling blocks for testing with accuracy and precision was the acquisition of Empty test cells, which are still out of stock at 18650 batterystore.

There is disagreement whether Only the welds carry current or if strips pressed tightly to cell before and after welding increase the contact area, and reduce resistance.

Also the welding Flux/ brazing paste poses another variable. The tinning adjacent to the welds might decrease resistance, or perhaps powdered tin and nickel in the flux add resistance to the weld points itself, post weld.

Why not test conductivity of welds on real cells?

I think the added cost and hassle of shipping live cells to Mooch was the reason.

He’s not needed. Can do the three-wire method or a precision tool.

Don’t let us stop you.

Please share your results.

That method removes the connecting wire resistance from the total but you still need a micro-ohmmeter. Do you have one with good enough accuracy?

My offer to test still stands but looks like we’ll be able to use your test results instead. Looking forward to seeing them!

I was thinking of the method where u apply a voltage and record the current and then can deduce the resistance and that way you can get around the need for the precision resistance meter which is expensive and I don’t have.

I didn’t read much of the thread and didn’t know you were planning to measure already. If you’re planning to measure the conductivity of the welds and have a precision resistance meter.. great and I’ll go back to sitting around.

That can definitely work if you have a voltage source that can supply enough current to get above the “noise floor” and is good enough to not drift over time or when it gets warm. You’ll also need an accurate enough meter to confirm your voltage setting. Then you’ll need a very accurate way to measure current, typically done with a high-accuracy (+/-0.25% or better) shunt and an accurate voltmeter.

But all that can be a huge problem with standard power supplies and the micro-ohms of resistance we”re dealing with here. Might be better to use a CC/CV power supply to limit the current and then confirm current level with the shunt and measure the voltage drop across the welds+strip. Ohm’s Law then gets you the resistance.

That lets you use a basic power supply and just depend on the voltmeter’s and shunt’s accuracy, easily done. Just get the current level up high enough to create a voltage drop that is accurately read by your voltmeter. A mV or two won’t cut it. You’ll need at least 100mV of voltage drop and a very good voltmeter to differentiate between different setups. Better to have several hundred mV of drop to make things even easier to differentiate between different setup resistances. I don’t know how much current that is though, you’ll have to run the numbers. Might be huge.

I’ll be using my BK Precision 8640 DC Resistance Meter (1uΩ resolution, 0.1% basic accuracy).

i don’t believe this for a second. you’re always up to something. ![]()

![]()

Been busy and working slowly, getting some good results with the p60 welder with .3 and flux. Once again finding pressure and position are critical. If welding too close to the edge you risk a blowout and the positive terminal is the biggest problem so far. Had to replace a cell i blasted a hole in the edge of the positive as i was making one of the series connections which sucked but i stopped the whole process and made a jig to mark the copper so i wouldn’t do that again.

Gear 400, double pulse, .30ms preheat. I think the foot switch sucks or something but im going to swap it out for one with a better reed switch and see. Sometimes it will cycle twice when im welding evern though i have the continuous welding timer set to 2 seconds. Super unnerving to be honest and makes welding up the packs stressful knowing every 10th weld might just double up. Set the welder to single pulse and manually do two that way when it happens i just get three welds instead of 4 and the occasional double hit doesn’t over do anything. Though none of the double (4 weld) spots look or act concerning - the .3 copper sucks the heat away so fast im not overly concerned

I’ve had my p20b fire twice with one pedal press, once.

It seemed to happen as I was releasing the pedal, and i thought maybe my foot twitched, and I dismissed the event.

Thankfully it was inconsequential.

To hear you are experiencing it regularly is dismaying, as building a 20s 5p, you’ve likely done more welds than me

I wonder if the switch needs some lube on the actual switch like Caig Deoxit D5.

I might open mine up and have a look.