I was inspired by Fliesss and @rey8801 on their DIY Direct drives hence i tried to make my own.

I’m not going for a high torque set up because this is for a lightweight cruiser build, hence i went with a single.

This current build was previously a gear drive, but had bad ground clearance on 97mm wheels, so my two options were to get/make a small gear drive, or a single hub/direct drive.

HUBS? Naaah, so let’s go with a single DD. Here’s what i did.

I got hold of a hub with one of these square channels, i believe this is an Inboard hub.

Should be a 5055 motor equivalent, but unknown kv. @landonkun had an Abec adapter for Elofty drives, and it was able to fit the holes on this hub with some minor adjustments. Nice! OH MY GOD WHAT ARE YOU DOINGNO STOP

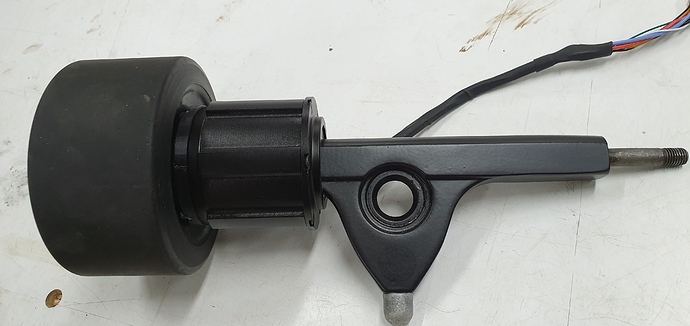

So uh i removed like 55mm worth of hangar.

Then it’s to file the square channel for the stator to sit into and not spin.

And that’s the ‘finished’ drive. The PLA adapter is just for test fitting, the final one will be printed in Nylon.

And here’s the finished look. Do note that this is purely #forscience and chances are that the axle will probably bend eventually. I’m not a heavy rider and this board is planned to be used for short distances on flat-ish terrain like going to the mall nearby etc. So fingers crossed.

Now, we’ve reached a wall. When running detection on both BLDC and FOC, there’s a weird crackling sound in the motor, as if there was something broken inside.

(what can i expect from un-named chinese motors am i right)

FOC was able to pass detection when increasing the amps to 10A, but when throttling, the sound and terrible vibration is still there. Ok you know what, listen for yourself from the video here.

I do plan to remove the motor can itself to check, but i have no idea how to remove it even after removing all bolts, as if it was pressed shut or something. I am open to other motor alternatives to retrofit on as well, as i have a couple spare hangars willing to test again FOR SCIENCE!

Am looking at the low kv 6355 Maytech motors, but am open to suggestions as well!