@Sender, I was wondering if I should paint deck(after light sanding) before applying spar urethane/epoxy or directly mixing a dye into the urethane/epoxy before applying. I just want a uniform black color.

Not to steal the question from @sender but figured I would answer it. Paint the deck first and then use spar/epoxy to coat it. Having a dye added to the epoxy with change the color however the epoxy layers on a board would be much thinner than what those river tables that everyone is doing that it probably would not be a solid black that you are looking for.

So there are things to unravel here.

In the tests I have done, regular paint, then clear coat wasn’t nearly as strong as say epoxy or poly on sanded wood.

The thing is, the resin bonds to the sanded deck much better than most paints. You are sort of installing a weak spot between the frit and the substrate (the deck).

Not that it won’t work, it will. Just may not last as long potentially.

That is why staining wood is better. You still get color, but you still get that good resin/deck bond.

I have been dabbling with pignented epoxy on decks lately. Like @Briman said, our layers are thinner than those 2" table pours you see online and to get get coverage that looks good takes a lot of time and effort.

For instance. You know what a regular Lacroix deck looks like?

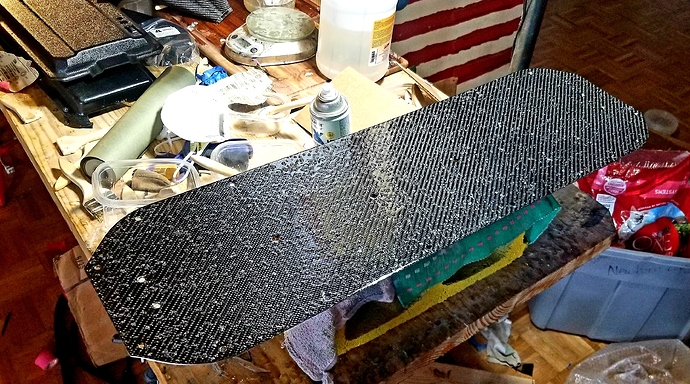

To get good white out on this deck took 5 coats of pigmented epoxy sanding between coats. That shit takes days. Then I did clear epoxy and the frit (and locked in the logo) and I still have some touch ups and edge work to do.

Sure I could have could have rattle canned the whole deck in 5 or 6 coats of spray paint and done the clear epoxy and frit. But I guarenfuckingtee this will be 10x more resilient and I am a glutton for punishment.

It all depends on what you are trying to do, your resources, and your level of patience.

I am going to get a haya hb83 short board and wanted to use glass frit on it and wondered how or if I need to sand down the aluminum cover.

Yes. Yes you need to. Sand it all down with 80-120 grit. Well.

I think it is good to skin the lid first. It will spread the load on the frit so it doesn’t pop off the fairly smoothe aluminum (even when it is sanded compared to something like wood)

Wow! Thanks for the detailed writeup. Cleared my doubts and confirmed by suspicions. I’ll most probably sand the deck and use dyed epoxy on it.

BTW, I found this cool gold black epoxy pour video.

If you are going to use any sort of pigments from what I have seen black diamond has some of the best colors and it seems to be heavily concentrated pigments so a little powder will go a long way. They also have a pearl that you can add in that has a nice effect. At least for tables and thick pours.

Bottom line comes down to epoxy will be stronger that poly it is because of the chemical makeup. But if you do enough coats of poly you can get a good thick protective layer. Waterbase poly depending on how many brushes you have and if you have nothing else to do you can do a coat about every 3 hours. I like to do thick coats as there is nothing wrong with more protection.

I agree with @sender with this quote,

However, I have never had a to touch up my glass frit on my first deck I did it on and that is on a push board that i did like 4 years ago and has been ridden hard. However I probably have alot more glass on the deck than send does because I just use a salt shaker and give it coat until ever inch has a good amount of glass on it.

When prepping aluminum for bonding (coatings are bonded to the surface) time is important. Epoxies and poly adhere well to aluminum. They don’t adhere as well to aluminum oxide. That is why the sanding is important, beyond just cleaning the surface. Sanding removes the thin aluminum oxide layer that forms on bare aluminum. The issue is the aluminum oxide reforms rather quickly. We specify a maximum of 24 hours between prepping and bonding with aluminum. I would consider that a good rule for how soon the first layer of epoxy or poly should go on aluminum after sanding.

Edit: I neglected to mention. We use Scotch-Brite rather than sandpaper. It doesn’t generate as much debris.

To me if your sanding you should be sanding then getting the dust from sanding off and then doing a coat.

I don’t know. We try not to set $200 million satellites on fire. I do have a great story about doing just that though.

Figured this thread would be the best place to ask this. Say I bought a longboard for either just pushing or top-mounting my enclosure to, and I really liked the bottom graphic and wanted to protect it against flying pebbles & scratching it when going down curbs. What would be the best thing to cover the bottom with for this? Ideally this could be something that I could reapply / mend every few months or so to keep the protective layer healthy

A good coat of epoxy may work, usually you want to sand the wood before putting epoxy down so it has more surface area to bond to…

@Sender may have some good ideas for ya

As @Itsmedant said epoxy would be good you and would want a very high grit sand paper to use just to light rough up the graphic. I’m actually refurbing a worn down and beaten Alva deck. And did 4 or 5 coats of polycrylic. It has almost like a smooth plastic feel now.

This is what it looked like

Also get some spraymax 2k clear coat to spray on over the epoxy.

@Sender @Briman

I’m curious On decks like the hummie and the lacroix is sanding enough to get good adhesion on the first layer. Or is any additional step needed to deal with the carbon fiber on top of those boards?

Thanks and great instructions!

What grit would you suggest? (So that I have a rough idea) Sanding the surface of the deck seems a bit scary, because I don’t know how thick the layer containing the graphic is. I wonder if hitting the deck with a rubber mallet with the sandpaper attached might be a good way to rough up the surface without actually tearing off the paint

Absolutely!

Just hit the CF with some 120 grit.

Some CF finishes have some sort of clear coat for UV protection. You kinda need to get that off and into the actual CF resin. 120 grit does this well

@rusins for that purpose, I would extremely lightly sand that graphic with like 400grit sand paper.

Then I would do two coats of spraymax 2k clear coat. It is $17 a can, but it is great stuff. I use it as my final cost on everything I do. Gives UV protection and it is strong.

I got two for 20$, let me find the link.

Edit : its no longer available ![]()

Damn that’s really fucking good. What site?

I don’t pay $17 because I pick it up in 6 or 12 packs. But haven’t found it for much lower than $17 shipped for a single can

It was on amazon, it was 20 +15 shipping, but with prime the shipping got taken away making it only 20.

It seems tho they made it 35 now with free shipping.

must have been a mistake or something.

Also have you tried the semi gloss or matte at all? I might buy it and see how it turns out.