The 3" Delrin rod arrived.

I decided that the most accurate way to cut it would be to CNC the top holes, which included the interface holes, so I threw it on the lathe, turned it more or less round and put a 1/4" hole in the center, then using that hole centered it into the mill.

Then just push the green button and out comes the top of the part

Then I manually turned down the other end (that will fit into the hub of the Kayak Carrier Wheels).

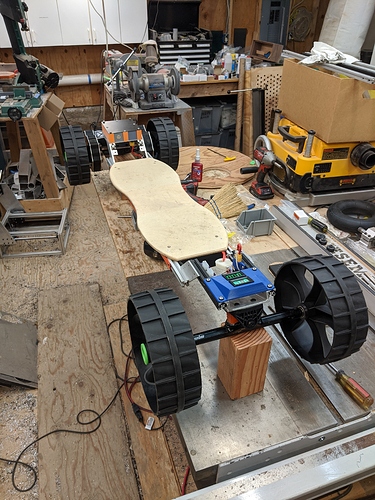

Here it is mounted to the truck, but not interfaced to the gearbox.

I did this 3 times. I know what you’re asking, why 3? Well, because I totally screwed the first one up and the outer bearing alignment with the inner bearing was 060 out which gave it an alarming amount of wobble. So that one had to be binned.

Also, in a moment of inattention I turned the wrong bearing OD on the wrong side, so I had to sleeve it, which wasn’t nearly as hard as I thought it would be. It’s nice to know I can save screwed up parts by sleeving them.

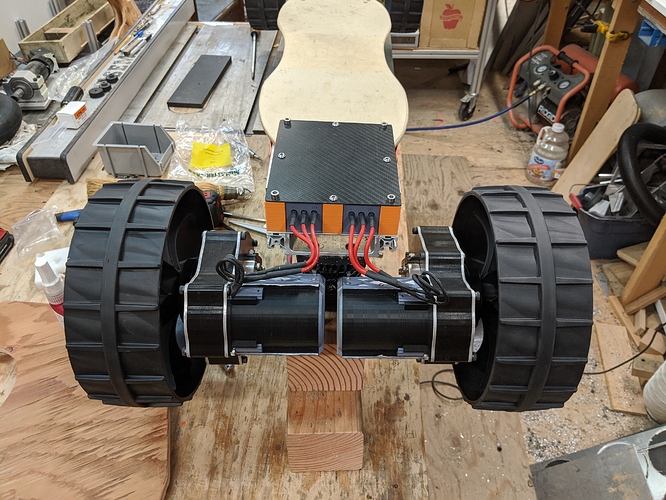

I 3D printed the gearbox interfaces, same as last time. I thought I had increased the distance from the interface holes to the edge a little bit but when I went to modify the gearbox interface I realized that all I had done was increase the OD of the part a little bit. Which should be fine - it was plenty strong last time (famous last words)

Anyway, I went ahead and got real rubber for the interface, so shouldn’t be shearing off any more irrigation hose. The rubber diameter is slightly larger.

I upgraded the motor cover vents from paper towels to cut-up desiccant packs which I think are tyvek

And I added a current meter but, unfortunately, the display is really dim, so it’s unlikely I’ll be able to see it in daylight on the beach.

But at least I have the sensor now, so I suppose a custom solution isn’t out of the realm of possibility

I’m waiting for a 90 degree micro-drill attachment for my Dremel so I can drill holes in the Kayak Carrier wheels to mount the hubs. It is supposed to arrive tomorrow, so with luck I’ll be back out road testing this thing by this weekend.

Then it’s back to the beach! Only this time I’m going to put something down in the car so it doesn’t end up full of sand like it did last time.