Hi there,

time to start a new thread over here about DIY wheel casting techniques, everyone with experience is invited to make it more complete.

I casted myself sleeves for hub motors resembling MBS AT wheels. I love these for driving without fear of wheels blocking, they survive even bigger stones since they tend to throw stuff away instead of locking it.

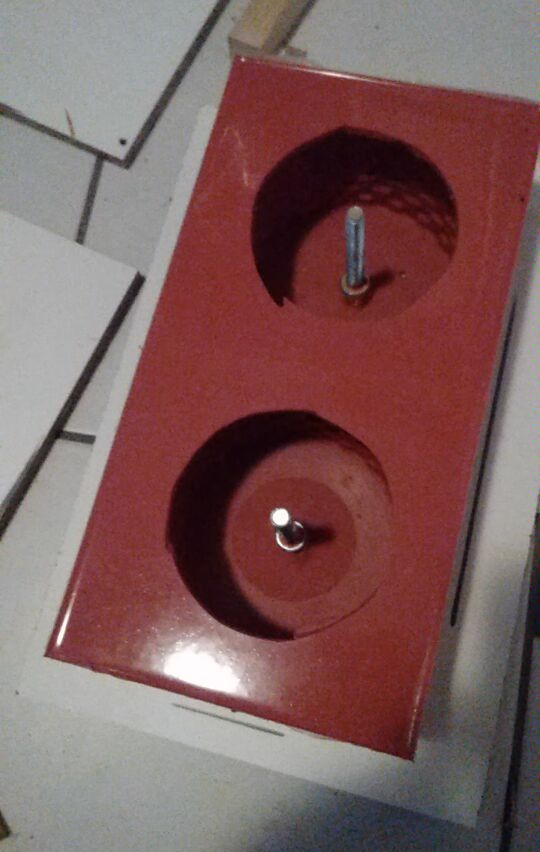

First I had to make the silicone mold. I used this silicone https://trollfactory.de/produkte/silikon-kautschuk/haertegrad-shore/mittel-shore-a26-45/7039/tfc-troll-factory-silikon-kautschuk-typ-3-hb-zinnguss-hitzebestaendig-rtv-1zu1 which might have been overkill. You actually need less material when you keep a box around it but it was the first time I did stuff like that  As you can see I put a M8 screw in there to behave like an axle, tried it before without centering aid which failed in a bumpy way

As you can see I put a M8 screw in there to behave like an axle, tried it before without centering aid which failed in a bumpy way  Its important to fix the screw really tight since it guarantees a centered wheel when the PU is cured. I then put the original wheels with bearings on top of these and filled all gaps with dough to force the silicone to the outside of the wheel only. After the silicone cured I removed the wheels and thats where we are now

Its important to fix the screw really tight since it guarantees a centered wheel when the PU is cured. I then put the original wheels with bearings on top of these and filled all gaps with dough to force the silicone to the outside of the wheel only. After the silicone cured I removed the wheels and thats where we are now

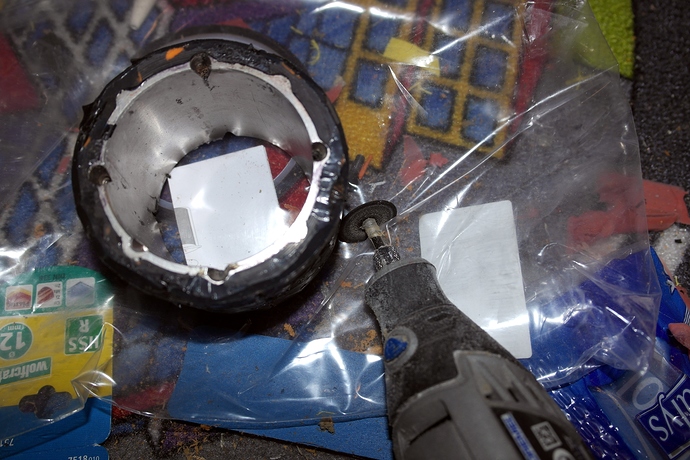

I prepared the sleeve with a dremel so the new PU can sink in the gaps to make a better bond. Later versions were just drilled like a swiss cheese, it was faster and more reliable that way.

After that preparation the sleeves were put in the silicone mold, centered by a printed centering cylinder (basically a cylinder with the same diameter as the inside of the sleeve and a axle-width hole in the middle)

Now I had to prepare the PU, in my case PMC-780 from Smoothon (https://www.smooth-on.com/products/pmc-780-dry/), a two component PU with shore 80A. According to Hummie its not the best material you can use but it was easily available for me. I used black PU pigment to get a dark black color for it to match the MBS wheels

After a little less than 2 days curing time it resulted in these wheels (Landwheel hubs):

Since then I used the same method for DIYeboard/Meepo style hubs and mellowboard hubs, all with great success. For a better finish I let the wheels spin and use a file to make them even on the outer sides.

Mellow:

I hope someone can use this little tutorial and more wheel casters will chime in like on the other forum