How do they work from a connection standpoint? Is it reasonable to assume I can buy two sets and get good range by using three and swapping those out with the second set?

They’re completely self contained in that each battery has its own BMS with a load balancing output.

You can simply hook them up in parallel to create a 10s1/2/3/4/5/6P battery. Charge and discharge is from the same 2-blade terminal. The batteries don’t come with the power distribution spine they use in their production board but I’ve got one handy im playing with.

I was wondering about the durability of the terminals and mechanical attachments. Would they hold up to many installation/removals if I followed the two set plan? What is in the power distribution spine beyond the parallel connections? I am not going to hold up my first build for this but maybe it is an option when I have to replace the battery in my Evolve. I have about 400 miles on it. I haven’t noticed any degradation yet but I am sure it is coming soon. That way if an airline plays bumper cars with my board it is not the one I built.

Sorry for all the questions, but your reward for answering questions in the Noob thread is more questions. One of these days I’ll attend an event and buy a few rounds.

Two more Noob questions and I promise to give you all a break for the rest of today.

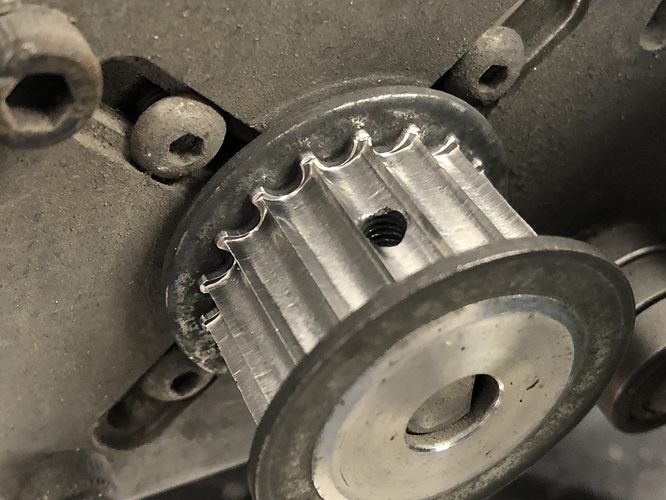

Does anyone really worry about having 6 teeth engaged in the belt calculator? That’s a nice theory but there are a lot of tolerances that would have to work out to have 6 teeth engaged simultaneously in the real world. It would force me to increase the center-to-center distance beyond what is absolutely required or decrease the gear ratio by increasing the number of teeth on the motor pulley.

Is it best to charge your batteries after every use, or better to let them discharge more? I do a 2 mile each way commute to work. Should I charge the board before I go out for a fun ride later in the evening even though it still has most of its range available?

The more teeth in mesh the better, less belt slip. Typically 5 it 6 teeth in mesh isn’t difficult assuming a 16t to 18t motor pulley. I assume you mean the motor pulley.

I think, and I in not sure, but I think it’s best practice to disagree to 30% then charge. 2 miles x 2 is nothing for even a 10s3p pack.

Motor pulley you want it to be as large as possible. Under 15 tooth is not good as they wear out too quickly, once worn they have sharp edges and will slip shredding belts in short order.

I like 20 tooth but that usually means using a very low kv motor.

Idlers help but don’t totally solve the issue.

Worn pulley

If your going for maximum battery life it’s best to keep them between 90% and 20% full. It’s the ends of the range that degrade the cell life.

There is a study that showed you can double cycle life just charging to 4.1v instead of 4.2v

I charge at home and work and go between 4.1 and 3.7v

Problem with that is finding a quality 10S BMS that balances at 4.10V/cell and is readily available and doesn’t do anything except battery management and a matching 41.0V 2A charger that doesn’t take a crap after a month.

I have yet to find those pieces.

So, until that happens, it’s 42.0V charging for me…

Is that the only way to do it? If someone stops a charge short of 100% the pack must still be stable. That means they must stay fairly balanced throughout the charge, at least close enough that there isn’t a big internal current surge if the charge is stopped. If that is correct and you can measure voltage you could do it by some simple automation to shut the power off to the charger.

Of course it could also be that any cell to cell current surge at all is more damaging than the last 10% of the charge.

Smart bms. You can just once program it to 4.1v and than disconnect any Bluetooth remote. Will work after like a normal bms

That fails the

requirement. I don’t want bluetooth on my BMS LoLz

Let’s dig into it…

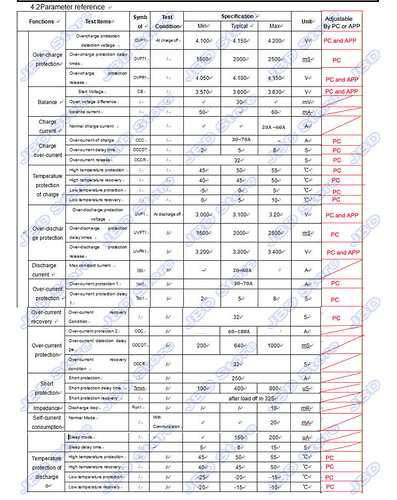

Smart bms, here the data sheet to which values you can set it up:

In case i set the overcharge protection to 4.1v and charge with a 42v Charger that should work, no?

And as the bms start balancing at 3.6v that would work as well as long as the cells don’t drift too much and you use a slow charger.

Oh man always the same…please read my full sentence. The bt module is connected with a jst. You can just fuck forget about it. Nobody need it. Get a programming cable and set once the values you want to have your bms at and you good. No bt, nothing. Just a fucking bms like the once you use right now in your boards.

I want things in the BMS hard-wired with resistors and stuff. It’s a failsafe circuit for a reason LoLz

I’d prefer less failures over a longer battery life.

So why you run than a vesc and not a hw programmed esc?  It’s not a fail save component?

It’s not a fail save component?

I think you slowly get what I mean. Just because something is new it doesn’t mean that it’s bad and if you are skeptical about something it might make a sense to get some information instead of just ignoring it…especially if it could be the answer to your needs… but everybody his own.

I need one of those things in 12S (and 10S too for later). Can you please tell me where did you find your information. I just got a bunch of Tattu and Turnigy Graphene lipos and I’m looking at a good quality BMS to charge them. Smart BMS seem a smart move

I bought mine here

https://s.click.aliexpress.com/e/M9v2nXG

Check the webshop of them to find the right one for your needs. This one was for lifepo4 cells, so I just sent them a message and they sent me one set up for lipo and LiIon.

Also check the description if you need the programming module. Theoretically you don’t need, but with pc you can change more parameters than with bt.

The only thing I miss on that bms when handling with lipos, that you cannot discharge to storage voltage.

Thanks a lot, Andy, it’s real valuable informations. I’ll dig the shop for some Lipo versions of those BMS.

To go to storage voltage (discharge or charge), I already have a duo hobby charger with 2x200W (and maybe we can charge to storage with the BMS if different profiles can be created)

I have a hobby charger as well here and that works pretty good for me. I can fast charge the lipos close to the time I want to go for a ride and after just hang them on the hobby charger to only charge them up till 3.8V. All in all that way save me 100-200$ to compare it with a hobby charger which could charge with 8-10A dual 6s lipos.

You can check the max min values in the AliExpress link or in the picture above. The min charge value seems to be 4.1V. So unfortunately it’s not possible to just set the overcharge protect to 3.8v when you just want to charge up to storage voltage.

this is why we bumped up to 16. 15T was wearing out almost as fast as the 36T nylon wheel pulleys. 16 lasts a good bit longer, and we don’t want to bump up to 17 or 18 without playing with some more wheel pulleys first. 16/36 on 100mm - 110mm wheels is ideal at the moment for us.

larger motor pulleys also means slightly better free roll.