Whoops I mixed them. Thank you, I’ll fix in your honor.

So are they or not? You guys keep confusing me.

These videos are great. i wish we had the equipment to make these sorts of graphs for eskate motors.

in theory, yes they should be.

BUT in reality were arguing over tiny percentages of efficiency. In reality belt tension, bearing quality, tyre pressure and a good gear ratio (that puts you in the efficient point of the motor at cursing speed) will make orders of magnitude more difference to overall efficiency.

yes I messed that up, let me try again

is the 100kv motor mated to a 1:3.5 gearbox less efficient than a 200kv motor mated to a 1:7 gearbox?

In theory yes. Also the 200kv motor will also be rated to a higher current so you can more total power out of this setup if you wanted to push it

You can’t say this in general. It really depends on your gearing and your riding style. Like I said before, at constant speed high kV is more efficient. If you accelerate often and hard a lower kV is more efficient. Same with gearing.

If you imagined the pulley was exactly the same size as the wheel, then pick whatever wheel size, and the torque is the same.

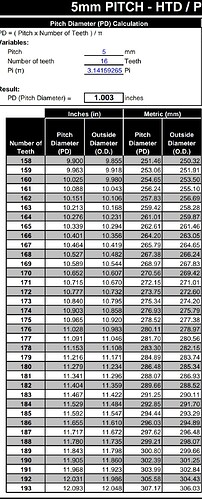

In your example btw, a 90T HTD 5M pulley would have a circumference of ~450mm => diameter of 143mm, or around 5.6 inches. Not bad for a 9 inch wheel or whatever.

I do see the appeal of this drive though: achieving higher torque than you could ever get with like a 14T motor pulley and idlers, or whatever is the realistic minimum we use.

However I don’t think adding another belt and pulley is worth it just to use a higher kv motor. (Extra inefficiencies from more moving parts) Would love to be proved wrong though.

im not sure your understanding whats being discussed here. Were not talking about changing the torque output of the system by changing the kv. Were saying that if you increase the motor kv and change the gear ratio so that the torque and speed at the wheel are the same, then the system is more efficient. it makes no difference if your at constant speed or under acceleration.

Very interesting build idea and looking forward to real world results.

Makes me wonder about the rolling resistance increase now with twice the amount of belts and pulleys involved.

Yeah 90t was just arbitrary number. You have to also factor in how many teeth on the motor pulley you can fit.

*click to expand chart

I don’t follow your logic here…you can’t just change the pulley diameter without affecting tooth count.

that was just a hypothetical example to show that “in an imaginary world where we didn’t need teeth / teeth were small enough to always fit”, if you scale the wheel up along with the pulley, the torque stays the same, because it’s literally just the torque your belt is experiencing

Thank you guys ![]()

Basically I just love to build stuff. I also sell an ordinary motor mount for belt drive. It’s completely fine bet yeah looking at the gearing 1:5 is almost the maximum there.

I would say 14T is the minimum you can really go at a mountainboard.

I’m not so after efficiency, nice to have if it is but thats not the main goal for me.

Thank you, really! ![]()

So a little story to tell from my first mountainboard. I got those Turnigy 6374 190kv motors and a gearing of 16/72. The motors are claimed for 100A and 4400W. But torque was not enough for me. So went down to 14/72. But I wasn’t very happy with the clearance and the the belt skipped sometimes. Installed idlers, but still to less clearence, broke some pulleys and belts from time to time. Also it is not a feeling you want when something of the board touches the ground and you loose contact to the ground with the wheels. So I decided to buy the same motors again but with 150kv so I could change the gearing to something like 15/66 or so, have similar torque and better clearance. But the 150kv motor can “just” push 80A. So i was disappointed because I did not get as much torque with this setup. Both (150&190) ran at 80A, but the 150kv performed worse. And the 190kv could push even more. So basically thats the story behind. May not be applied to general, just my experience with kv and gearing.

Trampa uses 1:6 gearing in the spur gear drive. I wanted something like that, but with better clearance and silent ![]()

Makes me wonder about the rolling resistance increase now with twice the amount of belts and pulleys involved.

Rolling resistance will be kinda very high, especially in contrast to a gear drive.

@Marsl187 this looks great. im just curious, why mount the motor so far out? if you have a 2 stage reduction you get a lot more flexibility for the motor to wheel distance, so why have the motor so far from the axle?

Thank you @ducktaperules! You always need some space between the two pulleys. You should not have less than 6 teeth in mesh of a pulley. Thats why you add idlers. Going back to the axle with the motor is not possible because it would touch the truck and the truck adapter, this also needs to be somewhere. The motor is not that much more away than in an ordinary belt drive. Maybe like the Trampa Urban Drive. Increasing the angle between the two stages is possible (45° at the moment) but then it could really touch the deck while turning when using a 35° Long from Trampa or so. With the most mountainboard decks it shouldn’t be a problem, but will definitely check it out. @brown5tick

BTW I did not really plan to make it a product. But when people are interested and if it works and performs well we can definitely find a way ![]() It might take some time (hopefully not that long) because it firstly have to build the mountainboard itself to test

It might take some time (hopefully not that long) because it firstly have to build the mountainboard itself to test ![]()

It is definitely not the best option. The designed gear drive is a lot smaller (fits in the diameter of the wheel) and with helicals would als quiet. But I think this is a good, easy to build and inexpensive system.

If you want to reduce the drag slightly you could reduce the belt width of the belt closer to the motor. This belt is under less load so can be thinner than the other

Very nice drive train idea with plenty of torque! ![]()

Higher gearing + higher KV = more torque = more fun

The gearing is easily changeable to even higher ratios. 1:8,5

Yeeeeeeeees do it! Paired with 250kv - 300kv motors on 9" with 12s and V6 and you have a real monster. Then you visit vienna and let me try it, deal?

I had different motors with different kv and gearings on the same MTB. IMO gearing makes much more difference than motor KV.

My change from 1:5 with 150kv on 8" to 1:6,25 with 200kv was epic. I can’t go back to 1:5 on this board. I have to admit the 200kv were 6384 motors but meanwhile I switched to 6374 motors in 220kv and even to 9". The difference is there but not dramatic, I just need to give more throttle to achieve almost the same torque as the 6384 in 200kv on 8". Only difference are the weaker brakes (with same settings), guess I need to increase the amps. With the 6384 the rear started to skid sideways on full brake, that was very funny.

With 150kv | 1:5 | 8" I could not climb steep hills from standstill. That was only possible when climbing at speed and during climbing it slowed down.

With 200kv/220kv | 1:6,25 | 8"/9" I can climb the same steep hills from standstill and if i give too much throttle during climbing I do an unintended wheelie.

just my 2 euro cents…

Hehe you can try the 1:7 version in Paris or Haldenhoppen hopefully. Or some other event in Germany. A shame that I haven‘t been able to join one so far.

I will use 6384 190kv and 8“ tires for now

Unexpected wheelies without full throttle are kind of the requirement for the drive

SOME UPDATES:

I finally received every part for the drive und also the laser cut plates.

I couldn’t resist and had to bolt all together and see how it looks on the truck

Directly started with cutting the threats for the M4 bolts and failed horribly

Broke one thread cutter and ruined three holes… Now waiting for new thread cutters (hopefully better quality) and longer bolts, so that I can use a locknut to tighten the bolt on the ruined holes (maybe more to come  )

)

For the future either directly use nuts and make the holes bigger or I’ll ask the laser cutter if they can do it with proper equipment (they offer this service)

The holes for the bearing went slightly to tight so I have to sand them a little bit bigger. Sometimes I really hate stainless steel

For the two middle pulleys which are on a shaft hold in place by bearings I originally planed to use a keyway for securing the pulley. Unfortunately it is nearly impossible to make one without a mill. So I decided to flatten the shaft at the spots where the grub screws sit. Everything glued with Loctite, so shouldn’t be a problem…

My printer is already running like crazy with the 3D printed parts. So with a little luck I can complete the drive within the next days. I’m going to make a separate build log for the mountainboard itself. Waiting for that @Haeroboards deck and the lipo for the spotwelder right now.

thanks for the update we’re rooting for ya

verzinkter stahl is da besser dran. auch für Gewinde.

Sorry for language change

Yeah problem is that galvanized steel isn’t that good for laser cutting (edges won’t have zinc anymore after cutting)