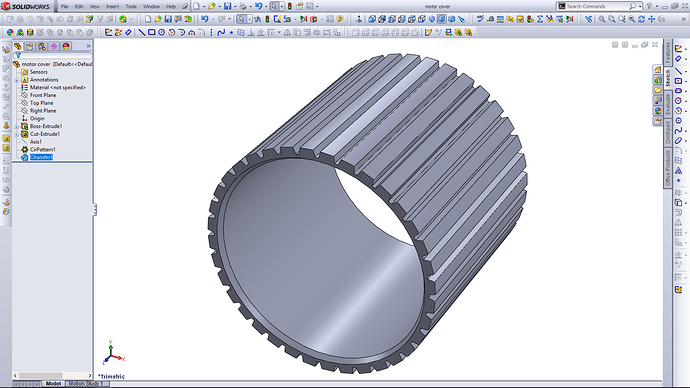

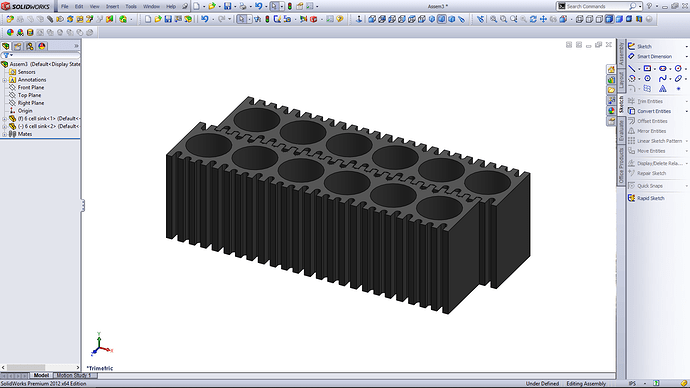

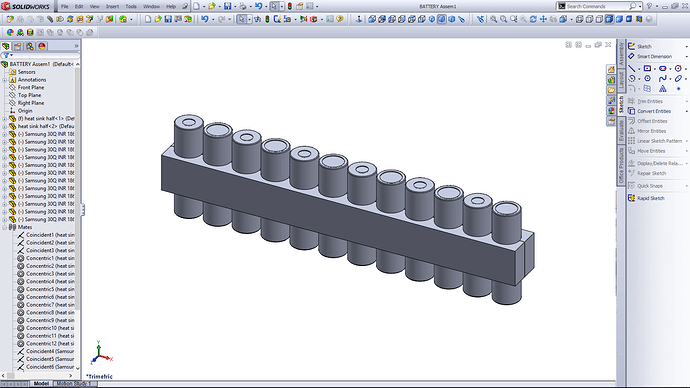

RipTide Sports has come up with a way to make Urethane conduct heat without conducting electricity. The compound is almost as heat efficient as Aluminum at half the weight and can be molded! We are looking for applications, any ideas? A couple of concepts we are considering are outrunner and direct drive sleeves to protect and bleed heat off the motor and battery holders. Conceptual photos are shown.

This is pretty cool

Heat conductive UT? Astonishing great esk8 applications. Your doorbell should get broken soon

Would normal UT used in direct drive sleeves mold to it without epoxy & shore? I.e. mold this as a sleeve then a thinner typical UT mix overlaid?

I can mold a wide variety of durometers and i think a interference fit of 1 to 2 mm will be adequate to keep it in place so finding the right duro may be the key

Could this be used for wheels cause what about Hummie Hubs. From what I have read the hub motors big drawback is that that heat from the motor just sit in the urethane and cause the heat to build up in the motors.

issue is i dont think the urathane would be great for roads

It is impossible for me to tell without trying it.

@RipTideSports that looks super interesting and open a lot of doors for us.

Do you think it would be possible to pour it around pcbs?

I think about covering the pcb of an esc, bms or antispark with it.

With it you would have a big heat sink and in the same time your electronics are saved up from any water damage.

Only advantage of that application is on hub motors, not sure Brian uses them. No point of having cool belt driven wheels…

Cheap chinese hubs are not really relevant given their lower power and general crapness,what’s the point

Best aftermarket and relevant application of hub motors is on

- Hummies

- R-SPEC DRIVE KIT

^ that is what you make

CoolThane™

Edit. What I am I talking about?

Not sure how to improve heat rating on hub which mount the wheel to end of the motor such as the TB or Swissboards or Elofty ones, presumably no advantage to the alum motor bell on a kit like this

Plus would have concerns over the ability to deflect any knocks or bangs and not have the whole unit come blow apart

There seems to be a general movement towards hub motors having the wheel on the end rather than over the bells, I’m guessing a lot has to do with getting the heat out of the motors. The problem with this is that the total width of the axle gets longer which means a much wider turning circle

So this application has legs, I’m guessing there is some R Spec owners who would love to have cooler ergo more efficient motors

why do i have a feeling there going to act like boa’s and chunk up

Nope; I don’t use hub motors.

If it actually maintains an electrical conductivity as low as standard urethane there may be a multi-function structure and heat rejection application. Load the urethane up with glass beads or just blow enough air into it to drop the density down to 1/3 or less of original. Make a sandwich board with whatever you like for face sheets (maple, bamboo, carbon, etc.) with the low density thermally conductive urethane as the core. Cut the sandwich in half through the core in a zig-zag pattern viewed from the side that will physically lock the two halves together later. Machine out pockets in the core to mount the circuit boards in. Bond high temperature components to the core with more urethane. Bolt the two halves back together. Now you have a structurally efficient board that helps reject heat from the electronics. Looking back over that the wood face sheets wouldn’t be the best choice. If you were building an aluminum board…

Meanwhile, somewhere in China, chips are now flying.

Yikes, I am trying to simplify my life…

If you develop a high end material, put it to high end use. Separating thermal and electrical conductivity is not an easy task with a dielectric. I am going to send a PM if you don’t mind.

Could you mold a phallic shaped sleeve with the intention of removing friction heat in 8 minute or so 120rpm applications?

Brad. You don’t need to reply, knowing that you read that and considered it is enough.

Graphite has excellent lubricant properties, you’re onto something as always

120 rpm? Careful you don’t exceed the eRPM limit on your controller.

Ambient hovers around 98.6F (37C) correct?

Maybe for normies, I’m super hot.