have you looked at hummies thread?

I have tried many times and still always end up failing to see the point of individual p-group pcbs.

Legendary.

Ordered both. Thank you very much, far to kind.

they look cool haha

I really think thats all it is

Others have already addressed the single nickel strip for the series connections and the lack of trimming the nickel.

However your battery will fail sooner or later due to lack of flex in this area.

Raptor decks are pretty stiff, I can’t get mine to does a lot so maybe it’ll survive

Maybe. Keep in mind that this is one of the failure points on the raptor space cells

Ok there is room for improvements (not physically though, the Battery compartment is fixed for now ). I am waiting on parts suggested by @bwahl602 atm.

The deck def. Not flexing a bit. If it would the plastic carrier would crack prob before anything.

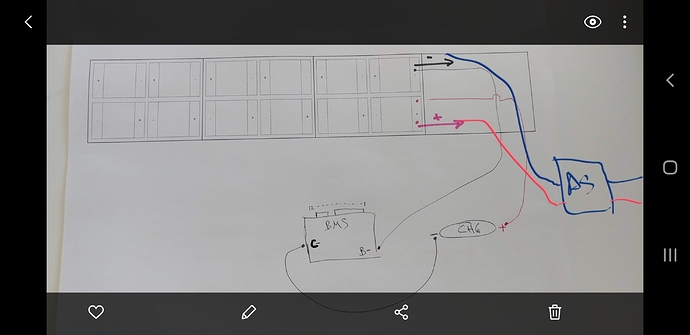

Which diagram is the one I should use as reference for building the split P pack?

(am bending nickel to go on top of the battery)

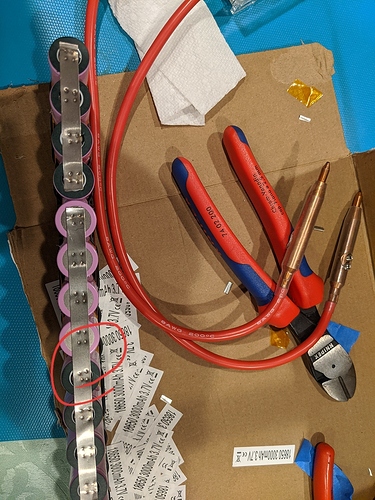

Blue = braided copper wire

Green = 10 awg wire

Red = nickel

Can’t turn the pack 90 degrees?

No this is the only way to fit it

If anyone can help my man @Resonant, he’s using my Malectrics spot welder with (I believe) 0.15mm nickel. Currently on vacation so we can only communicate online. Many thanks in advance!

i guess this leaves me out as well… ![]()

![]()

![]()

Lol I phrased that too quickly… I meant I don’t have my usual resources and time nor can I see him IRL.

Any tips for improving this? Also on the + side when welding the tab that folds over, I think it may have burnt the fishpaper? should I be welding the whole strip (the two on the sides at least that one be welding back onto a terminal) beforehand then weld the P group togther instead?

Edit: nevermind did a test on a practice cell, is it fine that this happens?

Shrink wrap on the bottom is fine

Whoa. I would never weld over the shoulder of the can. If it blows through the insulating layers there, you are welding a dead short. Only ever weld over the positive terminal of the cell.

Okay got it, ill just do the two sides and middle for the rest, should be fine in the end though? The rest of the packs like that and then the 1 in the picture. Given that I didn’t short those cells, from the test looks like it didn’t.