What rating is it for? (please be for 8a please be for 8a…)

Sorry man

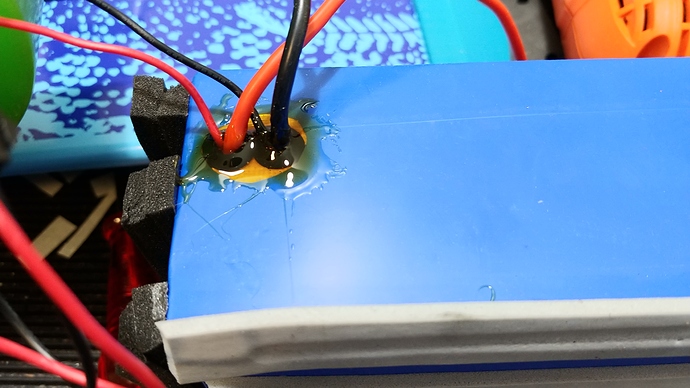

rip 5chr

I bought my fuses on ebay. They were so cheap

What’s the scale factor for fuses? I guess 2x is a good number

Thoughts on this one (15A version) for a 12s 8 a charger

150% of rating. Slow-blow.

Why slow-blow? Don’t the electronics on the BMS fry pretty quickly? Do the blade fuses count as slow blow or only the glass ceramic ones?

The fuse is there to protect your house from burning down, not the electronics. A slow-blow will be fine as you dont want to replace the fuse if theres a quick current spike when you plug the charger in.

Can I get 2 fuses please? 7.5 sounds good since I charge at 6.

just pm me

I understood that. Just wanted to point out for other people why not on the place where I marked or if you choose the positive terminal instead that you need to use some extra fishpaper there.

The packs themselves I usually seal the ends of the shrink with silicone.

For some prebuilt batteries, I use conformal coating

It all depends on the situation. You also have to consider the possibility of the shrink wrap rubbing a hole in itself under vibration, and water entering the hole.

How do you seal the end of a battery that is too long to shrink wrap? (Unless someone has 520mm shrink wrap). Just flood it with silicone?

You can brush neutral-cure silicone onto it.

I built a modular 10s7p pack (30Q) a while back that I can disassemble in 5 minutes and pack away in lipo bags for transport/air travel. Don’t have photos of the whole process, but took a few pictures. Each P grp has a balance lead coming out of the 3D printed casing.

Sizing things up:

All siliconed up, shoved in ABS 3D printed sleeves and about to get welded up.

3 out of 10 modules done

The lesson I learnt was: It’s annoying and challenging to keep 10 packs of batteries neatly organized in your deck. It’s a mess in my enclosure. The concept is nice, but the reality is that this didn’t work out as well as I planned. I ended up taping everything together to keep it in place during assembly and to not end up ragequitting. Sure, I can still undo the tape and disassemble my pack but it’s not as ideal of a solution as I was hoping for.

To make it function more like I was planning it to, I’m going to remove the ends of the 3D printed shells, dangly positive and negative wires and figure out a better way to connect the parallel groups to eachother. I want something that makes a satisfying click as I snap the batteries together.

If you’re taking the trouble to do all this (thanks), it’s very helpful to see what NOT to do (photos too). Maybe more useful than the good photos.

I’ve got a KWeld rig I’m building, looks beefy as hell. I’ll post when I have it operational and do some test welds.

Thank you! I hadn’t considered this! I’ll do my best to incorporate the bad ones too