Awesome! Thanks ![]() super helpful

super helpful

Hey guys.

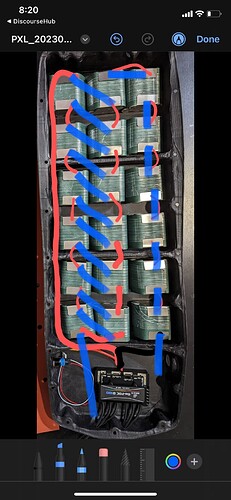

So this is a 12S4P with 40T cells I built a while back.

Currently lives in my Khymera build.

And I would like to ask on a scale of 1 to Kaboom, how much of a bomb is it right now???

Pretty notable voltage differences.

Do I need to take it out ASAP?

Is it ok to try to balance it?

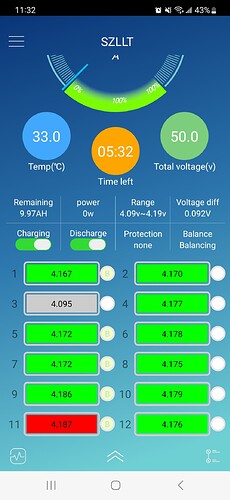

This was after riding a 4-5 miles last night.

And this is after charging.

I have set it to balance, and it’s slowly coming down.

Not super bomby. I’d get it perfectly balanced and try it just a little bit (going easy) and see if it breaks balance. If it does, it absolutely needs p-3 replaced. If it doesn’t, it’ll likely need a bms change.

I can’t emphasize enough how easy you need to take it when you bring the charge down.

And by perfectly balanced I mean ~ .020 delta

Co-sign w @Akbrock47 but I’d say that maybe replacing group 3 isn’t necessarily the right move. Cycle it a few times pay close attention to the groups that are highest and lowest and how they behave.

Group 3 is charging more slowly than the other groups and is well below the avg SOC but tbh, I think group 11 is more problematic and may have some broken welds. After your ride it was right in the middle of the avg voltage of your pack but then ended up as the highest group after your charge.

What are your parameters? Is the LLT set to charge to 50.4v? Did you try and take it to 50.4v during this charge? Did an overvoltage cutoff prevent you from completing the charge to full?

Yeah 11 seems to be having some bad issues too. Didn’t notice that.

I think they key takeaway is to do a bit more testing and really keep an eye on 3 and 11

Fairly certain I just have it set to charge at 50.4

And something I did not mention is this pack maybe 2-3 years old, and has seen lots of miles.

It is inching down slowly…

@Common_good It’s a bit of a project build that Ive started to think about (Dreamonseed) and collect bits for.

The CAD is just for me to use as a visual aid and isnt modelled, just 2D.

The reason for the weird pack is that I’m trying to fit an 18s into a single stack enclosure and modding the deck to suit. It was Cadding it up that got me thinking about the balance wires and how I was making the packs wasnt going to be simple with balance wires. So I had a look at it today when it wasnt 2am and came up with this which has the BMS at the back and I think the pack works if I havnt cocked it up.

If I’m on the right track I can continue making the packs while I wait for the nickel to arrive.

What voltage range does everyone’s (standard li-ion) packs roughly balance down to?

1) 4.10V - 4.15V

2) 4.15V - 4.20V

3) Over 4.20V

I’m trying to get a better idea where the existing BMS’ leave a pack after balancing. Thanks!

The poll feature isn’t working for me

Ive got three batteries that get frequent use and they all balance around 4.12 ~ 4.13

12s8p p42a diy and 200ish cycles

10s6p p42a diy and 600ish cycles.

10s4p Samsung inr? 10a cells ?cycles

Fucking incredible balance, modern lithium ions are so cool.

Based on the packs I build, using ANT, DALY and JBD BMSs, they all charge to about

4.15 New

4.12-4.15 after 100-500 cycles

Factory balance on the cells (After leaving packs idle for 2-3 days) is 0.02, after 100-500 cycles 0.02-0.035 or so. My own packs are all BAK CG50, LG M50LT and Molicel P42A and those tend to stick closer to 0.02 after time, but I also deal with a lot of chinese made scooter and ebike packs which almost always use LG MJ1, DLG 2600 or BAK 2500 cells and those drift more toward the 0.035-0.04 mark. They will still take 4.1v after balance tho

How do single-piece PCB packs hold up over time? Are they any more susceptible to vibrations compared to a flat pack?

This is all I found regarding PCB pack’s durability over time.

Wondering if a cell holder design could be combined with the PCB pack to reduce nickel stresses? Something like the snap together frames maybe?

My cells typically balance between 4.15-4.20. Both of my current boards have adound 20 cycles on them so the packs are babies.

Can my P-groups be touching negative to positive? Should there be fish paper or something else in between? Also, does anyone know any threads on securing everything inside the enclosure? I’ve seen people use double-sided tape, velcro, hot glue, foam, etc, Thanks!

I like to tape my groups together into a brick for each cell of the enclosure, if they will be touching neg2pos and it is a connection i am making with a series connection i will sometimes put a hard spacer just to make them sit together better mechanically but not necessarily to isolate them. I would put a bit of fish paper between and on the non series parts for extra cheap insurance against shorting if you have space or shrink it.

I put some ccf between these series parts for ascetics more than anything, then I shrunk the section, then cut open the shrink where I need to make the solder joints, then siliconed the joints:

I put some 1/8 adhesive neoprene under the package then 4 dime sized spots of silicone to hold it down after i was happy with it. Then i siliconed the edges in a way to not get under it so i can cut it out if i need to do repairs though it will be difficult

It’s unlikely to cause a shoulder short, but I’d advise putting a thin sheet of plastic in between anyways