Maybe 5k? We would need to checking.

Jeff could you give us the name for the worx oem factory? I think I’ve found it but just want to confirm.

Do you know who makes the Ryobi tools as well please?

Thank you

Send me message I can confirming for you if you have.

Ah that’s more than I was imagining. Dang it. Maybe if I find more people to go in as a group on it…

What would be the benefit? Just being lighter and thinner?

And blocking RF signals lol

5k is just for mould cost. It still need make some units for be cost effective. Our CF we use is expensive.

Depending on the price I’m down for one!

Wtf lol. Ryobi is TTI same as milwaukee and for the most part ridgid (cordless). Not sure about worx.

Stiffer but still vibration compliant, more resistant to damage from impacts on the edge, lighter, and looks cool? lol

Carbon skin one?

Eh, it’s not the same. The skin adds only a little bit of stiffness and mostly looks. Doesn’t have any of the benefits of a hollow foam core or impact resistance. It’s a good thought though…

How is a hollow foam core a more impact substrate than a plywood deck?

Stiffness would be related to the layup in both cases. The core material probably doesnt contribute that much to it…

Many strength come from the carbon fibre layup. The core material is so not have to use so much carbon. We using pre preg carbon fibre which have epoxy inlayed into the fabric already and need to be bake under pressure with autoclave. is very strong and can adjust weave pattern for strength and thickness for each part.

The foam core is of a high density with a different natural harmonic frequency than the carbon shell, together neither wants to vibrate with the other, creating a dead response that reduces high frequency fatigue. It’s been used in other carbon parts, like handlebars. Look up vibrocore that is the same concept.

I’m less interested in the name attached to them than what factory produces them. Jeff has cleared that up

is it too late to ask for a layer of cf be applied to the bottom of the neoone?

Can doing

ill pm you about the price and timeline

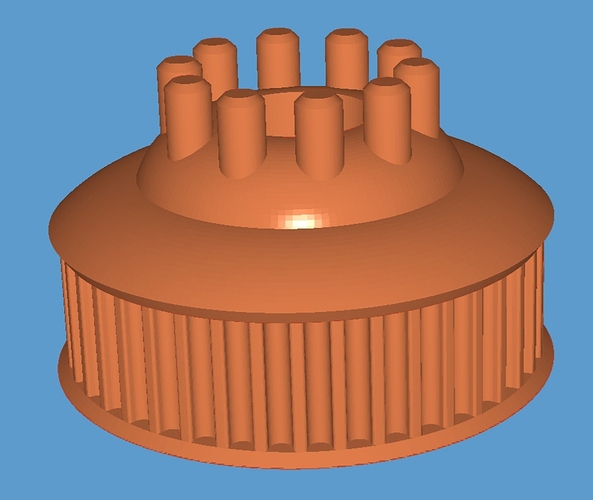

For pulley it would be something like this. 44t

Do you have a estimate for quantity/price for something like that?

I need file to see which size mould and kind we need making.