The first negative mold is done! Just needs to be sanded and filled in. Its pretty confidence inspiring that I’m able to hold it by the end without even having the bolts screwed in and its still rigid. It being 3 pieces instead of 12 definitely helps lol.

That’s hot ![]()

Super keen to see how this works out for you!

Clean!

Looks great!

I’m curious how many spools this took

About 3kg for this one. Its pretty optimized haha. And me buying my filament in bulk directly from a factory helps a lot. I pay $10/kg basically.

Another update on the custom BRP hubs. Preliminary quote is in and it looks like i am not going to just hit my target of <$200/set, but completely smash it. So, whoever wants in, the pricing is guaranteed to be below $200 delivered within the states for four of them. Final pricing dependent on how many parties i can get interested upfront. Could be significantly lower depending on how many sets i can get sold.

So, please fill out the below poll to indicate interest! (Please dont select an option unless you are fairly certain, as I’m fronting the cost of the run myself)

- Absolutely, I’m willing to pre-order right now

- Absolutely, but i need to wait a bit

- Possibly in the future

- Absolutely not

Would this be for 2 rear hubs only?

It’s a set of 4!

Set of four haha.

Sweet. I didn’t already order 53t pulleys, so please also put me down for a set of those for the BRP hub. Is the mbs pattern adapter a separate piece as well?

Shoot me a DM with what you want to order haha.

The MBS pattern is integrated into the hub, its a one piece design for strength and weight reasons.

I Voted, but I would prefer only a set of 2, 4 isnt bad though.

I’m absolutely willing to do that, shoot me a DM

Back in May of 2024 @Ac53n inquired to SRB about fabricating custom hubs for his personal project. We agreed to make these gave a quote and @Ac53n then stated he would look to have made overseas.

There is a big difference between copying for personal use and copying for profit. Especially when taking from a small business.

The BRP wheel for esk8 racing was exclusively developed and tested in a partnership between SRB and BRP over a 5 year period to bring it to where it is today.

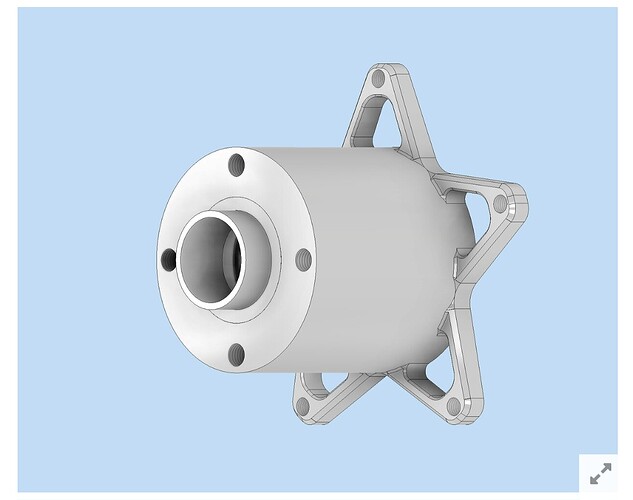

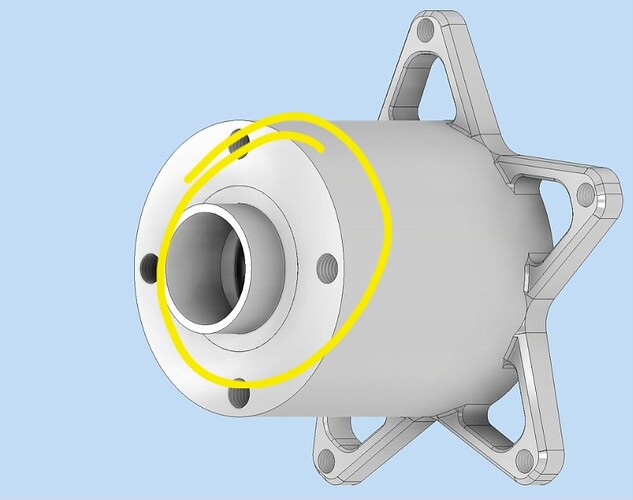

The SRB drive hub in the picture above was designed and built by SRB. There is nothing else available to adapt a BRP wheel to a 10mm or 12mm shaft, put a drive gear or belt cog on it and carry a human to 50 mph but this design.

From the knock out bearing spud cover in the front to the MBS pattern adapter on the back. This is 100% SRB design no one elses. The design above represents my time and work and sweat.

Sales from this design not only support my family but racing and wheel development.

We have watched what would be considered some pretty prominent esk8 companies disappear recently.

SRB is a husband and wife team. We run on thin margins and exist month to month from sales produced. It is a pretty simple formula. No sales = No SRB

When the rip-off 3-LINK design @newbiee tri-link was released, SRB 3-link truck sales suffered. Unfortunately the Newbee truck was garbage, putting overall the 3-link truck design in a bad light with users who bought into that scam. It hurt them, and us and everyone lost.

If it you cannot understand the damage done to mom and pop small business when this sort of thing is done I can only imagine that it is very dark place where yoir head is stuck.

When a customer requests a specialized part SRB does the best we can for our customers parts and service needs with what we have to work with. If you take away what we have, then nothing is what we eventually will have to work with.

If SRB stays silent as people steal for profit, SRB will soon no longer continue to exist.

To the people who dont see my behavior here as rational. Think about the time and work it takes anyone to problem solve and invent something new. A time consuming & costly trial and failure process that eventually takes a thought to an exclusive product that changes the way people do things. It is not as easy as making a CAD file and using an overseas manufacturer. As with the newbee truck, the physical R&D work part still needs done.

@Ac53n Cad design copy

Did you provide the designs to him under a license? Did that license prohibit commercial derivations of your design?

If the answer to either of these questions is no, then there is in fact no theft here; you have only yourself to blame for freely giving these designs away.

Even if you didn’t donate the designs, this part looks like it could easily be recreated by anyone somewhat competent in CAD with a pair of calipers.

The real value being added here is not the similarity to your part, but rather the innovation, weight reduction, interoperability, FEA, etc. that has gone into improving the BRP wheel interface. These are all things that you could’ve done if they were a priority to you, so I don’t see how you can blame someone else for producing parts with characteristics that they wanted when you clearly had no interest in implementing them yourself.

It’s ridiculous to see you repeatedly admonish innovation on top of your products simply because the existing versions are yours. If you want to remain in business and relevant to the scene, the way to achieve that is through continuous innovation, just like it took to get you to this point, not to attempt to tear down others doing the same.

Also, false.

Your correct. SRB does not have any protection.

Ours is simply am ethical argument not a legal one.

The point is small business is fragile.

If you dislike a product or the producers ethics You ultimately get to make the choice weather that business gets to stay in businesses or not.

If @Ac53n wished to take my hub design and make improvements through SRB with intent to take to market I would have been surely for that. There is a process to this.

He did not. He took our design and made it his own for his own.

What we have here is not innovation but taking our design work and livelihood in an unethical manner.

That is our ethical argument.

No bueno for humans. Ok for R/C made years after our spud system.

For development of the BRP wheel a load carrying spud needed developed and a place for a drive system. It carries the wheel weight so the studs do not. We tested and understood this long before 3D put this unsafe product to market.

Please understand that 3D BRP hubs are not safe @MacKeeper28 Copy That!

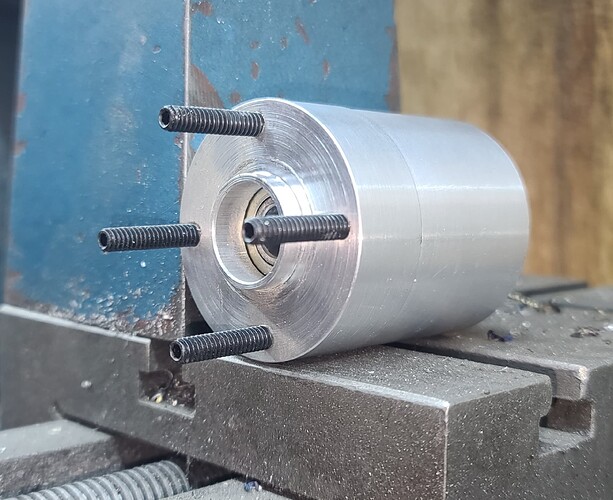

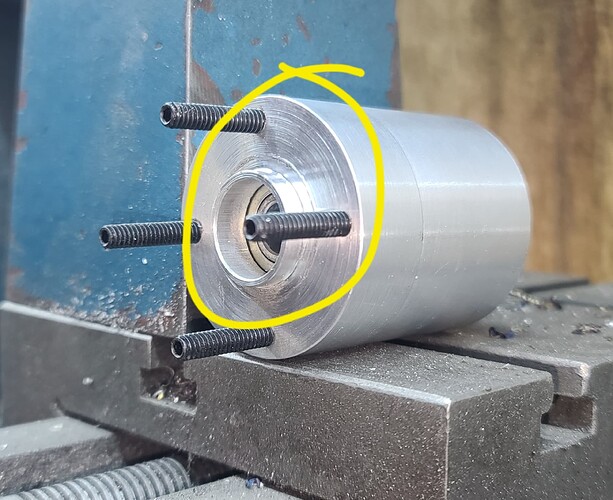

Took your design? With all due respect, after getting the initial quote from you, i found the pricing excessive, and the final implementation poor, to put things simply. It’s not exactly rocket science to slap a bearing seat onto a round bar stock and then add a bolt pattern to it. I’ll give it to you that the centering ring is neat, but again - its not exactly revolutionary, anyone who works on cars is all too familiar with hub centric mounting.

A sheet metal cut plate bolted onto a cylinder with bearing seats in it is… not exactly revolutionary. Is it your design? Absolutely. Is it yours to do with as you please? Absolutely. But… If an engineering student with zero industry connections was able to reverse engineer your product and improve on it in a one month timeframe, and then undercut pricing with a ridiculously small order quantity? With all due respect, it sounds like competition was needed And again - I’ve not copied. If the goal was just to copy, i could (with all due respect to your business), replicate the existing solution at an even lower cost to me, and make an even larger profit margin. You’ll notice, i am not. If you’ve been following the thread, you’d notice ive been iteratively improving on this design far beyond what any existing market solution achieves - because i strive to bring actual engineering design and optimization to our hobby. I’ve made 53T pulleys for the radium wheel core standard with no complaints or issues on that front. I’ve partnered with IDEA to manufacture drop brackets, and add the idea of making his SR TKP hangers reversible for adjusting the effective rake. And now, I’m making lightweight, one piece wheel hubs for BRP’s, as the existing solution is pricey, bulky, and not as sleek.

And mentioning small businesses, what exactly do you think i am? I’m not some large corporation squashing you under my foot. I’m a single person, using my engineering knowledge and skillset to manufacture parts that benefit the community as a whole when i see a demand.

“Think about the time and work it takes anyone to problem solve and invent something new. A time consuming & costly trial and failure process that eventually takes a thought to an exclusive product that changes the way people do things.”

As an engineer that has literally managed to do this in single week timelines? With all due respect, maybe compete instead of complaining about copies. Ultimately, I’m here to make the products we ride on better, and safer. As a whole, we can all agree on that sentiment and improve by competition, or stay stuck in our ways. I’ve made my choice - its your turn.

If your entire complaint hinges around the use of a centering ring, fuckit. I’ll design around this considering it no different from patent trolling. It’ll make the final product worse, and more expensive to manufacture- but i wont change the end price to buyers, I’ll eat this additional cost to redesign the hubs to not use your incredibly revolutionary and special centering rings.