The event is on East Pecos Rd is all lol

Ha! I didn’t notice that. Part of the origin of my nickname. Pecos bill is a folk tale from the az area.

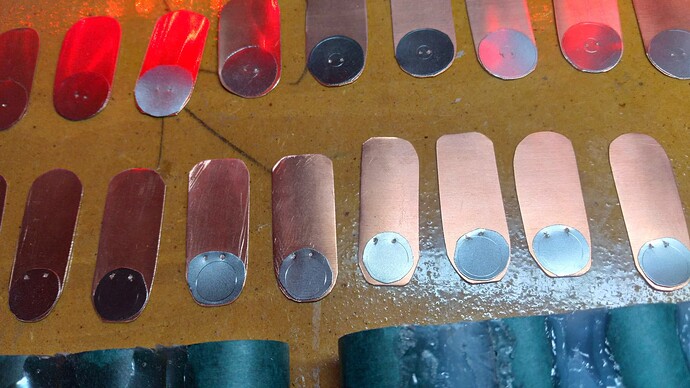

Damn that looks nice. Are you using the magic paste? How strong are the welds? What thickness copper? I did try direct copper no paste no nickel/steel but for me those welds weren’t strong enough for my liking. I don’t have paste so am doing the steel sandwich but it’s more tedious than what I’d hope for. That said the welds are really damn strong with the sandwich

Magic paste for sure, did a couple tear off tests with .1 steel sandwich but it was so fiddly and hard to be accurate with my welds. Very good tear off though.

Im using .3 mm copper with paste and a single pulse at gear 400 with .3ms preheat on the awithz p60f welder. The paste is fiddly in a different way but seems easier to get it all lined up and clean welds. The .3 copper is very strong and i can’t keep from damaging the cell with 4 weld spots and a single pair of welds needs to be rolled off leaving most of the weld on the cell. These are rs50 cells.

I have to leave a 2mm space from the outside edge of the copper strip because it doesn’t dissipate the heat around the weld sufficiently closer to the edge and i had a burn through when the welder did a double pulse - still trying to isolate why it’s doing that but the work around of leaving more clearance around the weld seems to be working well. A double pulse with enough surrounding material had very similar tear off so it’s not ideal but not causing any issues.

i am sandwiching.1mm steel for balance tabs just because it’s the only clean way i could work out - but dropping the weld power by half and getting very secure connection

Also made a little jig to mark the copper to get my pattern accurate, the .3 is so thick without it i was struggling

I’m making a cute little 10s1p Eve 40PL.

0.2mm copper with 0.1mm stainless steel.

I attach the stainless to the beforehand with a 002 gear pulse.

I scribe a circle with a sharpened awl for the10mm positive tab diameter and for the 6mm Spiral on can.

I attach the stainless to copper with gear 002 in the 6mm spiral, and outside the 10mm ring that I weld within on the positive.

Cutting scribing, positioning sandwich, and welding SS to copper is tedious, but then positioning the sandwich on the cell and welding that goes quickly.

I used the welding flux/brazing paste. Without it I need gear 520 to 580, with it I need gear 320 to 385. This is with the 14.6kw AwithZ P20B.

Stainless steel reduces the welder power required significantly, vs using nickel plated steel of same thickness. Just don’t think you can solder balance leads to stainless steel. SS is solder phobic.

TIL

Wonder if there’s some sort of flux that can counter this?

Very strong acid flux and very clean surface will let you solder ss but it isn’t ideal. Absolutely have to clean up all the flux very well of it will corrode copper and nickel. Usually it’s conductive but i haven’t messed with it in a long time. Also high silver bearing solder helps. The pure nickel or nickel plated steel seem to work.

i got a roll of nickel plated copper to test some connections with too. ill do more after i finish this pack

Fluxes containing hydrochloric acid, phosphoric acid, zinc chloride.

Given that there is already copper in the mix here, probably no advantage trying to solder to SS.

Nice, sounds like you got it dialed in decently. I should get some of that magic paste to try.

Good idea on the 3d prints, I should do that too. Is the right 3d print to push the fishpaper into the cell grooves nicely? I can’t help but notice how nice the fishpaper conforms to the cell grooves in your battery pic

That’s the tesa 51036 tape, high temp and flame resistant and a lot easier to conform to the cells. Then it gets some fish paper after welding where it needs more protection before heat shrinking

that block is for alignment - helps me get it centered up correctly on the template.

I’m confused lol

Did you? I’m curious, I did some similar stuff back in the days

Yeah, I did it. The Phoenix - Rise of a RE44 to racing glory

You should look up the Kaly XLR steering system

I have been trying to, but I can’t for the life of me find or otherwise get a hold of a concrete picture or description to tell me how it works.

I know they use a pwm output from a spintend which is how it is controlled based on speed, but apparently it is lots of effort to get the servo outputs working so I might just try get speed from vesc to arduino. Will be experimenting with the already exploded spintend.

But apart from that a big servo, more lasercut stuff and linear roller bearings is really easy hardware stuff

I had a hard time too.

i used to think it was a hydraulic dampner,

but i later started to suspect it was just tightening bushings.

I saw someone use this kind of motorcycle steering dampner

and heath lewis used the kind that’s more of a rod. and so did stooge boards a long time ago on early SRB.

You need an EUC with suspension…

@Yeahthatperson look at this kid go!!!