I heard a ticking that sounds like something about to break ![]()

I think thats because most of the parts is 3d printed. And the alloy plate is made in a cheap way…even tho the gear was seating in 3d printed core. Was trying to verify it in low budget.

Really cool imo.

(know one cares)(0.O)(just comment and let him know you think its cool af.)

Absolutely amazing work, and I’m just putting things together with the fact that you were behind the new trucks on the Revboard! I heard so much about them from Ryan and my brother.

Any chance we can hear in on numbers inside the gearbox? Like gear ratios and stuff

Stock set up of the gear drive of the Rev phantom x is 11/55, 5 gear ratio, but we accept custom order through email, you could choose 4 gear ratio gear drive…match with 6 inch semi slick tyre or 200mm MT tyre

SAT for racing( 0 rake)…i improved the ground clearances

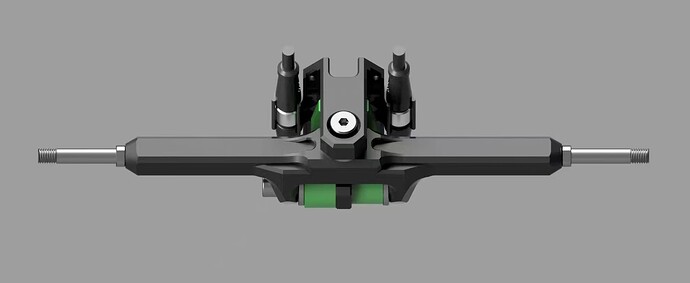

Specs: 280mm hanger width, 392mm full lengths…22*22mm profile…j think i going to get few set of sample.

Should i make special axle for brp? Can somebody tell me the lengths of bearing to bearing of the brp wheel

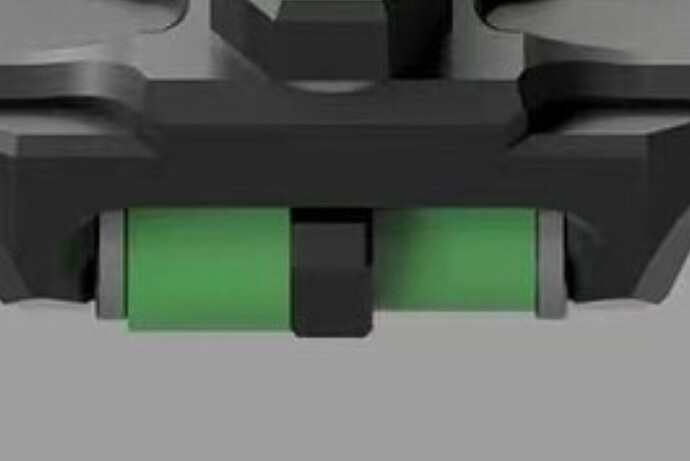

One side chubby one side barrel ![]()

![]()

![]()

You know one always hangs lower than the other

This looks epic! Like a duality but with a more uniform compression of the bushings.

Duality has completely uniform bushing compression, as the kingpin (technically queen pin) is free to move up and down. You are supposed to run the kingpin’s grub screw loose

I mean the plane of compression is constantly perpendicular to the axis going through the center of the bushing.

I did custom washer one side with thread, which are slide into the hanger, so one kinpin, you could equally compress the bushing. Tall bushing and regular bushing all suitable.

54mm bearing spread. id recommend 70mm axle length or longer, 65mm bare minimum but then you’d have to find nuts and sockets that fit the centering ring on the hubs