@ShutterShock should be doing a review video on the rev1 board which has the trucks on it in the near future

Thanks for letting me know that. I’m looking forward to getting my SAT asap as well. ![]()

I think he already did a review on the board.

He has 2 videos on the board with the second video being a first impression

Yee I did make a video here:

Only one though. This was a first ride impressions video of sorts not a review. I have two more coming, a range test, and then a full review. Doing full reviews on boards like this takes a lot of time.

What I will say about the SAT trucks is this. They have a learning curve, but have a lot of potential. For me, I couldn’t just hop directly on them and go 35 right away, it took some time to get used to how they react to bumps, find the right bushing tightness, and get used to how responsive they are.

These are unlike channels - there is no center deadzone, no hard bottom out, and no crazy amount of support. The center is very playful and quick to react, which in my experience so far means that when you hit bumps on the road, it can tend to transfer that to you quite a bit differently than with normal channels. It reacts sort of like PKP in that sense.

I’m still getting used to them to be honest but they have a lot of potential, and go a long ways to making the board not feel like a boat. It can turn in a single lane road no problem.

I tried a lot of things, from the strongest locktite, to retaining compound on the spherical, stiffer beefier linkages, hardened hardware cut to the exact length to maximize thread engagement, steel helicoil inserts in aluminum portion, bolt spacers to optimize the rod angles, 3d designed brackes to optimize rod angles and got a quote to have machined but it was absurd. Probably tried some other things that I’m forgetting too. I got some good rides, and a few hundred miles out of them and hit close to 40 mph. They felt pretty decent, but not earth shattering to me. Ultimately I deemed them a hazard because I couldn’t get the hardware to reliably stay in.

So now they are sitting on the shelf. Imho they needed a lot more meat at the nose to handle the forces when using aluminum. There just was not enough bolt engagement. I think the rod angles could have been optimized better as well.

Right now the trucks are sitting on the shelf collecting dust. Learning tig welding is on my list, so maybe I’ll blow the dust off and make some Frankenstein version some day. Back to the Hoyt Rosa for now.

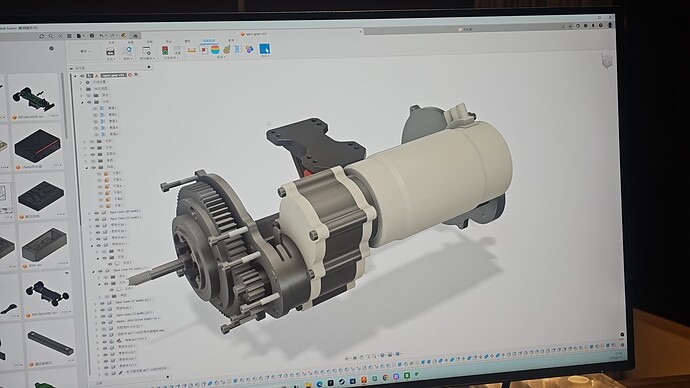

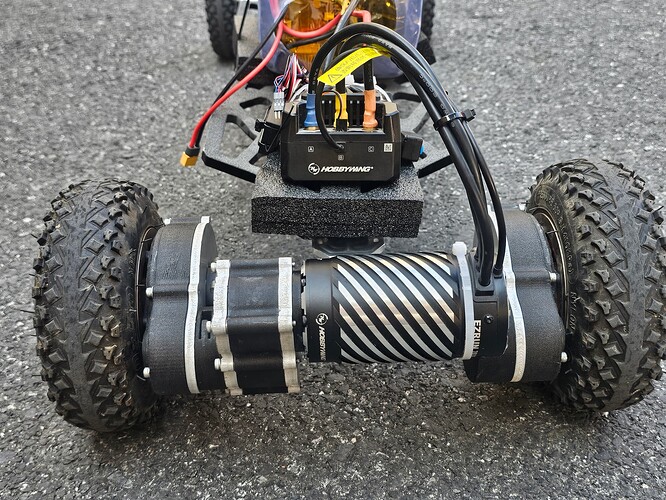

so this is a dual gear reduction drive?

am i right?

with gear shifter? ![]()

tho i thought he was working on a differential? one motor two driven wheels.

Lever to lock/unlock the diff?

Wow thts new shit

Yeppp, you getting there.

so just to make things clear

its a dual stage gear reduction where you can set the gearing with a little lever?

its not a differential?

does it spin both wheels?

KR

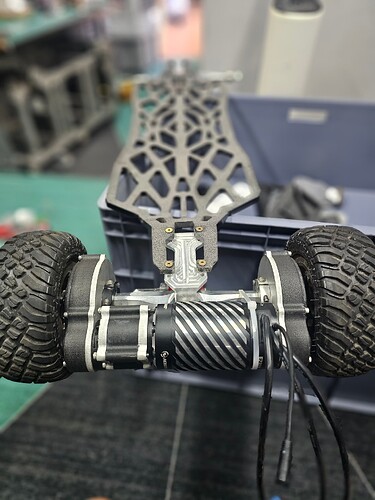

There is a shaft that drives both wheels, you can see it in this video:

I assume the lever will allow you to lock/unlock the axle depending on if you want both wheels turning together or not.

I think the deck looks really cool

driving videos please!!!

looks really promising

also the sound is nice

thx man