Saw this post on fb about EUC motors and temps.

TL;DR; where the motor temp sensors are changes what kind of reading you get.

Winding temperature reaching 150deg C easily, however the Hall Sensor location was only reaching 100deg C, and magnets were only 60deg C.

I’ve never thought about where our esk8 motors put the temperature sensors. Also I wonder if they’d have as much variance as a big EUC motor since they’re so much smaller.

full post:

Motor Overheating Story Time

Background Context:

In China, during testing - Zac Darnell and Brian Dillard were able to overheat the wheel at the Fugang Race Circuit (Brian after 5.5 laps, and Zac after 7-8 laps). Because Brian is taller, and heavier - he was able to get motor overtemp alarm/tiltback earlier.The motor temp sensor overheat value was set at 140deg C. We wanted to test slowly - to prevent injury of the riders - therefore we started to test the motors 10deg C at a time to determine where issues may start to appear.

The concern of high temps in motors is for the following sensitive items:

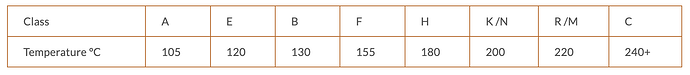

- Hall Sensor - 150deg C

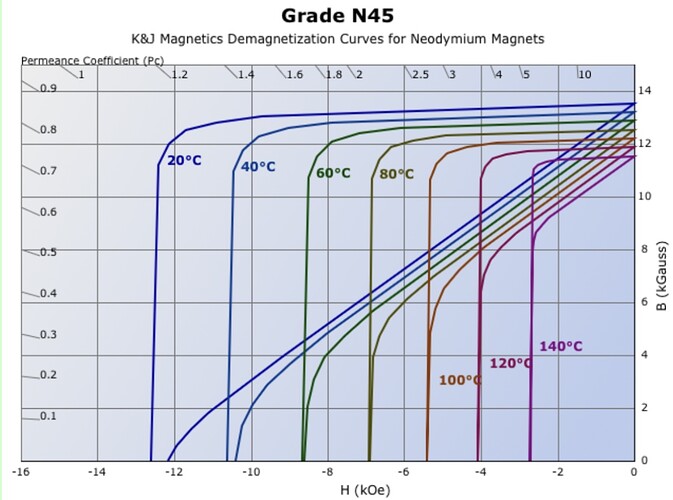

- Magnets - 140deg C

- Winding Insulation - 200deg C

As we started to raise the temperature limits, we hit a snag at around 150deg C - where the aluminum motor cover was expanding thermally at a rate greater than the Steel bearing. This was causing the fitment on the motor cover to allow for bearing play - which resulted in rotation during high torque applications. The result: The stator could come in contact with the rotor at the edges, when high torque is applied.

We worked with the supplier to modify the tolerances on between the two surfaces - in order to be able to withstand higher temperatures before the motor plate would have too much play on the new motors (Hence why we had to do the motor swaps to the new production motors that had better tolerancing)

Kuji’s review unit was operating on the newer motor, but the firmware that contained the 150deg C limit. Therefore he triggered the motor overtemp tiltback after 15min of sustained 60mph riding.

At AVS, we didn’t have any issues of overheating - until the end when we had consecutive demos on the P6 by multiple riders on track back to back.

At TEF1, we wanted to continue validating the motor overheating concern. Mario, Brian, and Aaron? were able to overheat the motors during the practice laps/qualifiers ~8-10 laps - and during the practice/qualifiers we tested the motors up to 170deg C without any issues.

When Mark returned to China, we wanted to validate the temperature readings once more - after the changes were made and we found a couple findings:

The Temperature sensor mounted in the motor - was mounted directly on the copper windings. (This is the heat source, and therefore it would be the first thing to heat up)

As we were worried about the three items: Hall Sensor, Magnets, and Winding Insulation, we focused on 2 things:

Validating the readings of the thermistor to ensure that the readings are true to temp.

Run additional sensors at the Hall Sensor location and Magnets in order to validate the temperature differential due to material (plastic) insulation and air gap (to the magnets)

Our Findings:

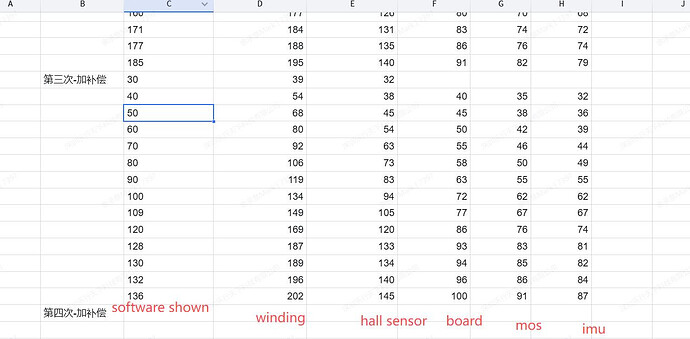

- Winding temperature reaching 150deg C easily, however the Hall Sensor location was only reaching 100deg C, and magnets were only 60deg C.Therefore, we ran the temperature test on the motor dyno in order to validate the temperatures at each region - as well as the temperatures on the control board, mosfets, and IMU to ensure that there are also no temperature issues on the control board. We ran the overheat test on the motor/control board until we eventually broke the motor.

Results:

- We have now validated and calibrated the temperature sensor readings, and have updated the sensor fusion in order to properly calculate the motor temps at the critical areas.

- As per the tests, a rider should be able to sustain 60-70mph for approximately 35-45 mins continuous before the P6 will tiltback to prevent any potential for damage or injury.Next Steps :

- Over the next week or two, we will validate the temperature on the full-wheel dyno. Once complete, we will then do real world validation.

– from facebook: https://www.facebook.com/groups/1961754117563127/posts/2025563427848862/.