Oven cleaner. Very easy

Does that depend on how deep the oxide layer is? Not sure but sanding half a mm can still be painful lol

If the mounting plates aren’t (re)made yet, maybe @surfnacho could save some $ by not having them anodized. That if its a fact that a raw surface transfers heat better than an anodized one.(which I have no idea, me dumdum)

I do wanna reiterate that it’s still gonna help with heat. These optimizations are more for those pushing amp limits on speed demon builds or poorly geared mountain boards (me)

Hey, thanks for your concern, however the ano cost is very little, does not make it or break it. The shipping cost is significantly higher than the cost to anodize. All of these places do black ano all day everyday, so it is very cheap.

@Agressivstreetlamp and I were talking about doing a v2 with thermal dissipation optimization. We would be doing a lot of research and testing to figure out the most optimal design. Maybe we could even talk to thermal engineers etc. Robin found that onshape has some cool tools built in for sims and stuff, so definitely something I would be interested in doing in the future for a v2.

200lb me in the hills, but wanna be

Lol

Lol me too!. I’m just glad nobody saw me hike up the hill with board in tow ![]() had to wait at the top of every hill for things to cool off.

had to wait at the top of every hill for things to cool off.

Those thermal tools do look super nice. Especially.since you already have the models. That said, Pretty sure we could just stick @bourbon_norm in a room with a pencil, a slide rule ,a piece of paper and a bottle of single malt and he’d figure this out. old school engineers really impress me. Here I need a calculator for every little task.

For sure, I bet Mike would be super helpful with this.

@bourbon_norm if you can help with the v2, you can have all the free heatsinks you want

I’m pretty sure I’m going to need some serious heat sinks.

I live at the top of a pretty long/ steep hill, and I’m surrounded by even more of them to get anywhere.

It’s literally downhill no matter which direction I go from my house. So it’s always uphill home.

I dragged my board up that hill at Sycamore Canyon for the whole world to see so I am interested. The thing about heat distribution is interfaces are the killer. Where ever you bolt things together and you want heat to transfer across that joint. To be efficient about it you need very high distributed pressure or something with high thermal conductivity that fills all the tiny local hills and valleys. Conductive RTV (room temperature vulcanizing silicone) or Grafoil are two common choices. We would be better off with Grafoil since we want to be able to unbolt the interface after.

A thermal interface material will fundamentally lower the thermal resistance as long as the two surfaces are parallel and flat over their surfaces. They don’t have to be smooth, just not warped or uneven.

Graphene is great for lateral heat transfer, not great for this.

Pastes/compounds without silicone oil are a better long term option as they don’t “bleed”, separate, or dry out over time. Phase change materials (waxes) are incredible and what I use for high power stuff but can be quite expensive. Not needed here IMHO.

Use a layer thin enough to see through. You don’t want the plates to float on the stuff, that’s useless. You just want to fill in the low spots. All the original metal-to-metal contact should still be made. About 0.5mil, 1/2000th inch, thick is a good place to start. Basically, a film.

Press the plates together and rub them in a circle to spread everything evenly and thin. Then peel apart and make sure the coverage was 100%. Spread it again and bolt everything together. Only tiny bead of compound should appear at the edges but it should be all around.

There are also “gap pads“, rubbery pads of thermal interface material. They are not nearly as efficient as pastes due to the pad’s thickness but they are convenient and you have a lot of surface area to play with. Get the thinnest pad you can find, you don’t need to compensate for rough surfaces.

I recommend not trying that as the roughness and unevenness added using any hand procedure will cause an increase in the thermal resistance of the gap larger than what the anodizing caused.

Anodizing is a true insulator but the thickness is so tiny that the thermal resistance just isn’t impacted that much. Specially at heat flux levels this low with a surface this large.

I recommend not removing it as the unevenness added by doing this by hand can cause an increase in the thermal resistance larger than what the anodizing did.

Plate flatness and smoothness, of both surfaces, is critical. But so is getting the heat to the plate. If the ESC does not have a low thermal resistance from the FETs to the plate then our efforts with the heat sink are for naught.

Anodizing is a true thermal insulator but it definitely can increase emissivity. But radiative cooling might not be the primary path for cooling here IMO. Convection is probably how most of the heat is lost. Testing would need to be done, with the sink inside an enclosure and with the fins sticking through to the outside.

It will never hurt to have raw surfaces touching and increased fin surface area though. But if the ESC is anodized where it touches the ESC plate then a bit efficiency is lost there. Not much we can do about that though.

Optimizing the thermal resistance chain from the junction (inside) of the FETs to ambient air is critical. Any thermal bottleneck will zap that efficiency.

Something I definitely anticipated.

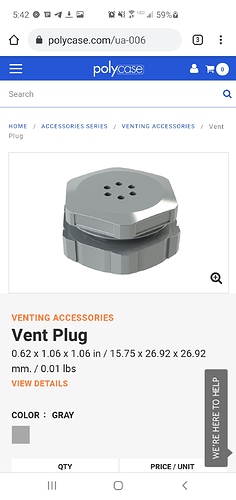

How do you think a waterproof vent plug like this would fare in equalizing with ambient temperature of an enclosure?

I imagine heat building up inside with the batteries and enclosure and leaking out but it could be minimal cooling.

Grafoil would be quite convenient (cost?) but most decent pastes outperform Grafoil. Grafoil is fantastic laterally but through its thickness it only has a fraction of the thermal transfer efficiency.

I’d love to see a comparison between them, would the “numbers” differences translate into real temperature differences in this application? Is the mess of paste worth the theoretical performance increase? The heat flux levels are pretty low.

Agreed, minimal to no practical effect. Convective cooling will have a MUCH bigger effect.

That’s all my top Mount box has atm. I didn’t consider I might need more…