Next where gonna see a Wareno ( Wife Dareno)

Next where gonna see a Wareno ( Wife Dareno)

That’s a tough topic, since there is little to no data about the stresses that a board is subjected

For a simple calculation, consider a heavy dude with all the weight on just one truck and aim for a safety factor of 8 to 10

The best way to do it is to do all the fatigue life calculations and aim for infinite life, but again we get to the same barrier that there is no dynamic loading data that we could apply

What you will have on the middle of the axle? The walls look way too thin

And to be honest I think is really risk for you to change the design for kickstarter, you have a proven design, stick with for now, do a few of your new design and ride for a few thousand kilometers before selling it

@topcloud i hope the motors live up to ur endorsement thank u, but you gotta admit there’s a resistance when unpowered and wish you’d got them now with this new stator design that can be afforded.that will make the roll on par with anything out there so it seems.

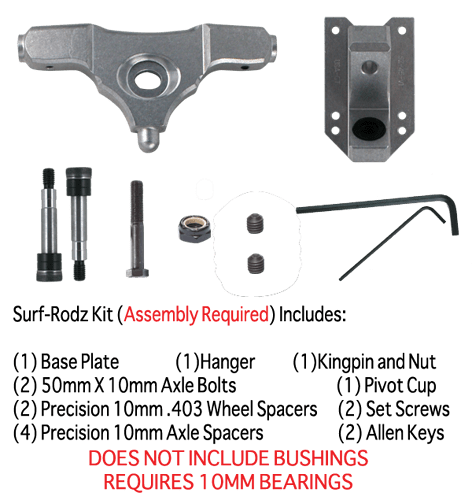

@Pedrodemio. I will get work on making it stronger there maybe but I think it can be misleading with the pics I posted and theres a big hole where there normally is a small 8 or 10mm axle… I could model a version of surfrodz or some other aluminum hanger and show the mass at the different lengths and I bet this is at least double nearing triple. I cant even find what type of aluminum they use. do they break ever? what other aluminum hangers have broken? silverfish longboarding is gone and maybe so is the info.

What is wrong with the 12mm axle?.. I was kinda hoping someone would make a narrow width hanger for the hubs to make a mini board lol

![]()

![]()

![]()

ps what will prevent the stator cores from unscrewing themselves from the aluminum threads in the new design?

R

This print isn’t even what I showed modeled and it hangs way low but u can see the difference in size. nothing was wrong with the 12mm axle before other than it wasn’t precision straight and wasn’t near what this is for cooling. THAT is why do @Titoxd1000 this. this design maximizes space and in this age of cnc machining this is possible. it’s an advancement.

And these typical surf rodz trucks. Before even modeling and simulating the obvious faith comes from designs that have come before. Are there any broken surf rodz and what aluminum are they even using I didn’t see. A sliver of material in comparison

(These are some 90 duro tires I poured for the luge for going high speed. Unfortunately we’re waiting on him getting the escs together to get it going.)

This may sound crazy, but since you say you have a load of regular (non grill) hangers already made, how about just selling those as the standard, aka stealth version and design an optional bolt on aluminum grill/diffuser plate. It would be a win win for those who need stealth or don’t weigh much or don’t ride hard, and options for those who want to push the limits of these things. Could even be a two plate grill cover that sandwiches the hanger with bolts to clamp them to the truck. Something like this, but beefier and with your hanger in the middle.

Even crazier would be to add a tunnel/channel through the grill with fittings to accommodate tubing that can be routed to a small water/liquid cooling system.

@Mobutusan this would be precision straight as apposed to cast. that’s the benefit of these machined aluminum hangers. cooling is kind of an extra.

Altough progression is fun, I can’t help to feel like a guiniepig for these new changes that I’ve payed a good price for. Maybe it’ll be great, maybe it’ll hold etc. From a proffessional standpoint I’d love to see some factual data of what these hangers actually contribute in terms of power dissipation versus a normal truck. I mean its a hollow axle that is transfering heat onto a solid block. How many more watts does it really dissipate compared to anything else? Are these changes really worth it if the benefit is less then 10%?

Also the inability to mount the motors on anything else EXCEPT these monsters must be a major dissadvantage overall. Again, is it worth it? I’m excited for the cable funnel, but not at the price of everything else.

All in all, major design revisions 99/100 times require iteration. How will you fund this if it turns out theres a major flaw in your currently proposed design? Shipping out new machined hangers to cover broken/unusable ones? I know you frequently dig out of your own pocket but all this can be avoided if progress is made in the right manner.

every version ive done of motors over the last 5 years now I think have been done on paper. Sure id get some prototypes to test but not for long really and how long would be long enough?

I can model the heat transfer too and that would be easier to simulate actually. the older design has a pretty awful heat transfer ability compared to this and I bet it shows a big improvement in max continuous output power while staying under such and such temp.

for sure this design can be made to outlast any person who would get them plus. I don’t think strength is worth questioning really as its going to be huge. there are variables that need to be taken into account, solely mass, material, and shape and how the load would be applied and it can be shown how strong something is with a good simulation. I don’t even think enertions thin aluminum hanger broke on the actual hanger or if it did it was one of the rarer fails with those. those were likely cheap aluminum but regardless the material they used is a small fraction of this. let me get it represented with the wheel and all and you can see.

esthetically it may not be for everyone and I can accept that but don’t assume it need be weaker and as I say theres many other aluminum hangers out there, doing the testing for us, and then we add like 3x the mass.

we want precision! we want awesome cooling. we want its aesthetics. we want what it could be used for.

but need not happen. an option

I’m not trying to mock your process John, I have mad respect for you doing what you do. Nothing but love for your motors. I just want you to try think of what you’ll do in worst case scenarios, worst planning is not planing at all. It’s great that you belive in your designs and that they’ll work out but nothing is risk free.

In the end I’m powerless, you’re the one who has the final say how you want to develop and what you want to deliver. I’m simply sharing my mind. I’m all for everything positive in these changes. I just hope you have time to really prove the design and get some hours on them before you spit out a truck load of hangers that end up as paper weights.

i want us all to believe in good stress modeling. things aren’t done. far from it. its the direction worth going though i think. i think we can all be convinced with some good science behind it and i want to get that done and show you and see what you think then.

If/when I could/can afford to back this, I would, but I would definitely want solid steel axles. Even better if it’s one piece from side to side and not threaded into aluminum.

Back when I was into LDP, I saw many CNC billet slalom trucks appear, some in the $600 range, break a few times, several revisions, etc. This taught me to fear new truck designs.

I’ve also seen many photos of broken grade 8 kingpins.

I like innovation but maybe in small batches until it proves itself over time.

what about these days what aluminum hangers are snapping?

we shouldn’t assume it cant be done. surely a hanger with good ground clearance and not hitting the bushings or deck can be made that has an assumed lifetime of maybe 100,000 big hits or something. they design aluminum parts with fatigue taken into consideration. I don’t know but bet aluminum hangers these days aren’t breaking often but even if they were we would be making nothing like them…we’re talking over 3x the mass. forgetting fancy computers would you agree that if we made a hanger that literally had 3x the mass at all sections of surfrodz for example, that this hanger would likely be pretty indestructible. that’s what im wanting to do. of course it depends on shape and stuff and we wouldn’t be doing that hanger shape but besides that I still feel strongly an aluminum hanger can be made that would maybe even outlast the 12mm hangers. they aren’t an assured anything really and we don’t necessarily know they couldn’t shear or something or fatigue crack. its been shown to happen before. and that’s why I instinctually think we go monsterously large. You cant assume just because its aluminum it has risks.

but its all talk and im getting helps from experts on modeling and simulating and I still believe a giant aluminum hanger is our better option in so many ways. look at the cooling it showed to do for @mimin. he isn’t over here I guess. he milled a giant hanger for the raptor hubs and showed how well it cooled. he went from standard raptor hanger to something similarly large as this I don’t know exactly.

endless-sphere has a good thread showing internal motor temperatures beyond what they would find on the case. heat is the enemy especially with these direct drives. we get great cooling and way over-built construction in one. this connection to the hanger ill get the thermal modeling and we will see. maybe im wrong and will have to model the old to contrast.

and we go a bit longer. bigger motor. and the custom 15tooth stator. if we have the money to get it all done, which we just have, then I think its the best way to go. we’re in the future we grab the reins and go and we see what we end up with and in maybe a week we have some stress test results and maybe an option or two for esthetics or something and get feedback from all in. we don’t do what I did in the past, trust me this is worlds better, we make something fantastic and fresh empowered by what is possible. its like Im trying to do a vw bug for farrarri trade-in and hearing the color is too hot and that there’s too much aluminum in it.

I like those ideas! I’m curious why not just make the axle one-piece instead of two pieces? You could do both…

I think people want you to advance, innovate and improve. Just… not with their money. You marketed these as the hubs you’re selling. They are tried and tested, they are solid. People love them.

Now you want to do something new half way through a campaign. Surely you can see that’s bat shit crazy hummer? Help me out here.

VS

I think what’s making people nervous is not so much the design and improvements, but the thought of gambling the entire kickstarter campaign on a single iteration.

It seems reasonable to make a buttload of the bulletproof design that you’ve perfected over a long period, and while selling that buttload, start testing a new design, making it bulletproof.

I’m tiptoe-ing to avoid offending you lol. We’re all into what you’ve been doing and what you accomplished. We want it to keep going.

This is good advice.

How many first iterations of designs just straight up work? I’d wager that percentage is low.

all the past motors were just on paper and relating it to other stuff out there. the idea that its unsafe terrain it always has been. I changed a bunch of times and lost money and it doesn’t bother me and just want to make the best thing we can. I believe, again, it can be done not just on paper but with modeling and computers.

what I have up as a pic may not even represent what it shows to be and I want everyones input to make it be something. im about to send files to a brad and someone else to look at stress testing. all I ask is you don’t count aluminum hangers out.

yea I want to change it. I said somewhere why and I have to develop new stuff after making different stuff and learning and want the best things. Im not trying to make a business but fulfill a design goal. to make something that can go up and down mountains at 25-30 mph all day. that’s the sport. its a sports vehicle.

at this point I think no one has bailed on the kickstarter. if I can show an aluminum hanger showing better strength than the old design, i hope that will happen. I believe it can be designed so it does do that and more, and it looks nice. let’s see.

at the root of it everyone has their bucks and can do what they want and back out till the end so any naysayers on changing things, i hope they can realize the potential they have here to be included in making the hanger. we could get all our faces put on it for all i know…and im seeing what shapes and what not is possible