Sounds awesome. The old timer in our group was telling me about all of the spots he used to snowboard in that area. Sounds like a great place to live.

Last time I took this board out the retaining compound on the motor pinion failed and disengaged with the driven gear. It was field repairable enough to finish the ride, but it happens more often than I want to deal with so decided that a life of cleaning motor shafts and pinions and re-applying retaining compound just isn’t for me.

Good bye helicals! Into the bag until I can figure out your purpose in life.

I picked up these Jump Drives from another forum member a few months ago. Been hesitant to use them because they’re probably the last pair I’ll get my hands on. Also the helical thing was still an issue without Apex motors. Slightly less of an issue since the helical gears are directional on the Jump Drives but failures can still happen.

So far, the SLM printed gears on the other build have been holding up great. Definitely still in the testing stage but they’ve taken some abuse and are still running strong. My confidence in the technology is growing so decided to make a SLM printed herringbone gear set for the Jump Drive.

This set is printed with a stronger grade of stainless than the set that’s on the Double Agent Build. They’re 17-4ph with a rating of 1150-1300mpa as opposed to the last set of 316l at 590-700mpa. Hoping this is a win because it’s a relatively cheap upgrade that could make these drives more reliable when using non Apex motors. Everything seems to mesh well. Here’s a quick video of bench testing the free spin. I’ll try to get it out this weekend for some real testing.

Here are the files, and some notes if anyone else is interested

Kind of important, Craftcloud3d.com is a 3rd party site that gets quotes from different manufacturers to print whatever you upload (except firearms, lame). The cheapest option is not always the best. I’ve had good luck with Shenzen3d. ProtoTi is usually the cheapest. They’ve been fine for enclosures and basic stuff but don’t use them for gears.

The motor keyway is 3.1mm wide in the design instead of 3mm. With Shenzen3d this seems to be the perfect size. Their tolerances make openings like this slightly smaller than the model.

You need to drill and tap the driven gears. Pilot holes are in the model but are slightly smaller than the size needed to tap the gear. Tapping stainless is no fun. Go slow or better yet, spend a little more and order them in merging steel instead of stainless. Probably a better choice anyways.

Ordering multiples of the same file makes the cost per item drop quite a bit. A group buy could save everyone a lot. Order at your own risk!

Files are in STL format because that’s what Shenzen 3d requests but I can share other types if wanted.

80T JJ driven Herringbone-LorR.stl (1.2 MB)

80T JJ driven Herringbone-RorL.stl (1.2 MB)

JJ 10mm 16t Master Herringbone.stl (436.8 KB)

STEP files below. Only one side of the driven gear but just create a mirror image of it for the other side.

80T JJ driven Herringbone-JumpDrive80tHerringBone.step (8.0 MB)

Where do you get these SLM parts made?

Craftcloud3d.com. Check the drop-down below the video in my previous comment for the files and some notes. Not all vendors on there are the same.

Thanks, totally missed the dropdown.

It would be great if you could publish the files in STEP

Added them below the STL files.

Finally got a chance to test these retrofit herringbone SLM gears in the Jump Drives today. 19 mile run, about 50-50 asphalt and rocky hard packed dirt. They definitely exceeded my expectations.

The free roll is much better than the complete SLM “Beer Drive” system that I designed. Guessing this is due to the rotary shaft seal in the Jump Drives vs the TPU seal in the Beer Drives. Going to have to change things up on the other board to accept a rotary seal. Using 17-4ph stainless instead of 316l probably helped too. The surface of the gears is much cleaner.

Hoping some of you will start experimenting with SLM. It’s already being used in more demanding applications and is pretty damn cheap for a small batch, especially when you consider what machined herringbone gears would cost. I’ll keep trying to break these things in both boards but knock on wood, so far they’ve handled everything I’ve thrown at them.

Spring in full force up here. Hope you all are enjoying great riding weather.

How’s that beer? ![]()

Awesome. Well worth the trade. It’s more of a piney than citrus taste which is pretty rare in an IPA.

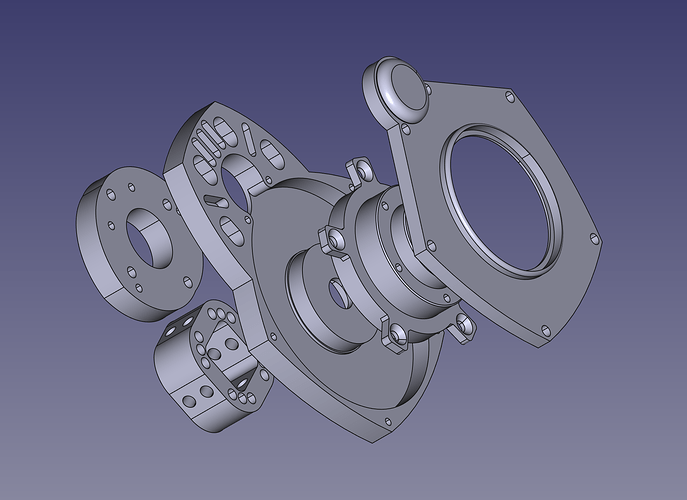

New gear drive time! I’m finally getting around to installing what should be the final version of these SLM herringbone mountain board gear drives, dubbed Beer Drives. I’ll make a post about them eventually but until all of my thoughts are organized they’ll live here.

The goal of this project is to have a reliable herringbone gear drive without proprietary parts. Replacement parts can be ordered from Craftcloud or any other SLM manufacturing service. Cost of production is cheap when comparing to small production runs of CNC parts (or at least any I could find.)

These are extremely DIY… You’ll be doing a lot of tapping. You might want to do something about the raw aluminum parts finish. These aren’t quick to put together but depending on what you want out of a gear drive, the juice may be worth the squeeze.

Drive Information

- The gears are mod 1.1 herringbone at a ratio of 16:80. Any mod is achievable without special tooling using SLM production.

- Truck clamps are set up for 22 x 22mm hanger. The truck clamp file could be edited to fit 20x20.

- Hub push fit adapters can be chosen for MBS Rockstar II XL or Trampa Phatladz.

Drive Files STL

JJ 10mm 16t Master Herringbone.stl (436.8 KB)

80T JJ driven Herringbone-RorL.stl (1.2 MB)

80T JJ driven Herringbone-LorR.stl (1.2 MB)

Beer Drives Remastered Gear Adapter 1mmH.stl (741.9 KB)

Beer Drives Remastered Gear Tubs.stl (1.1 MB)

Beer Drives Remastered -Motor Puck.3mf (102.6 KB)

Beer Drives Remastered -Truck Clamp.3mf (147.0 KB)

Beer Drives Remastered Tub Cover Deeper Cuts.stl (1.1 MB)

MBS Rockstar Pro II XL Hub Push Fit Adapter (16mm Height).3mf (98.5 KB)

Phatladz Push Fit Hub Adapter V1.stl (286.4 KB)

Individual CAD Files

Beer Drives Remastered Truck Clamp.step (182.7 KB)

Beer Drives Remastered Gear Adapter 1MM Higher.step (290.2 KB)

Beer Drives Remastered Tub Cover Deeper Cuts.step (146.2 KB)

Beer Drives Remastered Main Housing WITH SLOTS.step (478.3 KB)

Beer Drives Remastered Motor Puck.step (83.4 KB)

Beer Drives Remastered Main Housing 1mm Higher Gear Adapter.FCStd (908.5 KB)

I don’t have CAD files for the gears or push fit adapters.

Complete CAD File

Beer Drives Remastered Main Housing 1mm Higher Gear Adapter.FCStd (893.9 KB)

Hardware and Other Parts Needed

-Update exact hardware count

- 50 x 58 x 4 rotary shaft seal x2

- 6808 Bearings x2

- 6001-2rs bearings x2

Assembly

You’ll need high quality M4 taps and drill bits for the M300 miraging steel gears.

Threads in aluminum can be made with lower quality taps.

Always run the appropriate size drill bit before tapping. The manufactured holes are a little tight.

Tap tap tap. You’re going to be doing a lot of tapping.

Use green Loctite 648 or stronger on bolts securing the gear adapter to the gear threads.

Permatex red 27140 or equivalent for grub screws in truck adapter to hanger. Same for bolts that pass through truck adapter and thread into back of gear housing.

Blue stuff for all other hardware

You will likely need to file the bore of your motor pinions. A chainsaw file works great for this. Run a precision file through the motor pinion keyway opening to remove rough surfaces and get rid of excess material. SLM openings print a little smaller so don’t be surprised if you’re filing for awhile. It’s better than printing an opening that’s too loose.

SLM surfaces have a slightly rough surface. This includes your gear teeth. Don’t worry! Run the gears for awhile and they’ll break in. You could probably use lapping compound but it really isn’t necessary.

Ordering

All of the STL files are here. 3d print everything and test fit your setup before ordering the final product.

As of right now, 2-15-26, Craftcloud price is $393.04 including shipping to California. That’s only one pair of drives. Cost is significantly less per unit if you add more.

You’ll still need hardware, bearings & rotary shaft seals, plus any surface treatment you might want. Some of the vendors on Craftcloud will anodize the aluminum parts if you message them after the order. My cheap ass just painted the aluminum.

You can pick push fit adapters for MBS Rockstar II XL or for Trampa Phatladz. Easy enough to make push fit adapter files for any other hub you might want.

The gears are mod 1.1 herringbone. Yes, 1.1. No special tooling is needed to produce these so you can do what you want with the teeth. The extra .1 adds a little strength.

Choose M300 Maraging steel for gears. It’s the strongest material available. I still have gears made with 17-4 ph stainless that have been running great for almost a year. M300 is an even better choice so pay the slight extra cost.

The aluminum parts are made from Aluminum (AlSi10Mg). Between the time of having these parts made and posting this a new aluminum option, 6061 exists. It costs a little more but may be a better material. I haven’t looked into it enough yet but also haven’t had issues with the cheaper option.

Some general shit I’ve learned about ordering SLM parts

Bearing catches print with a slightly smaller diameter. Bearing seats print with a slightly larger diameter. Each part is sized to accommodate. The adjustments are just based on my experience but everything fit really well on this order. It’s better to have to file a little than have a loose fit.

Less material = less cost. It’s additive manufacturing. The more you can take out of the model the cheaper it is.

Obvious but the more of a single part you order, the cheaper the cost is per unit. It makes a huge difference.

Some of the manufacturers on Craftcloud will work with you on declaration values for import purposes.

It doesn’t cost extra to add engraving to the model. You can really personalize these how you want to.

Hey these look a lot like Jump Drives…

Yes they do. The goal was to make something that used their push fit adapter design, along with their rotary shaft seal. I also picked their same basic housing shape of a pentagon with a riser. It’s not an exact match but it’s really damn close. Same goes for the gear adapter. I experimented with other shapes but the one they already came up with really is the best solution for connecting the push fit adapter to the driven gear. The similarities are obvious.

These files and an explanation of intent were sent to Lee and Ben before posting. I told them I wouldn’t do it if they had a problem with it.

So you going to take them down some stairs and up some curbs?

Dude I am going to do so many kick flips with this drive, you have no idea.

How is wear on the ones you’ve been running for a while? And how much torque does the board have that it’s on? I kinda want to try using SLM for my double stage drive.

How many sets do you have out in the wild so far?

No fatigue related failures like cracking or such with any SLM gears?

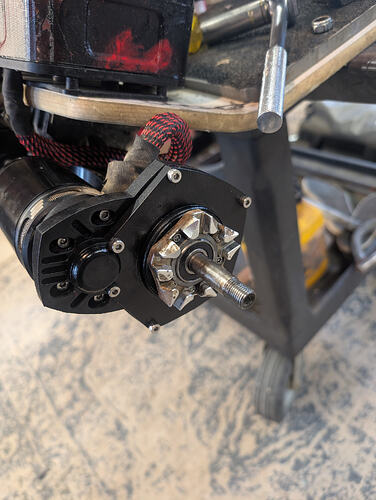

There’s a set of these gears installed in a Jump Drive on one of the boards. Same modulus of 1.1 and same tooth count at 16:80. The metal used for them is 17-4ph stainless which isn’t as strong as M300 maraging steel. Here’s a photo of the pinion. No damage that I can see.

Not sure how to figure out how much torque. It’s on 173kv 6395 reachers with an 18s battery. Motor amps are set to 100 if that helps.

Thanks, looks good! I’ll give this a go when I get to the inrunner upgrade

Hell yeah!! I’m loving this project, it would be such a cool Discovery to learn that metal 3D printed gears are effective for our hobby. We talked about this already in private but yeah I’m so excited to learn from your project to improve mine ![]()