I wanted a CNC mill for a long time now, mostly to mill esk8 parts. The opportunity just came and I grabbed it. Just found an 800kg/1750lbs monster on ebay kleinanzeigen (german ebay) for 1400€ which would give me a very robust and (hopefully) precise base to work with. And most importantly one that I can fit through a doorway. This thread will be an ongoing thread which documents my progress on getting this running and getting it upgraded.

It’s a CNC engraver from 1988, called the Kuhlmann Prokomat P20T and it has 400x400x100 travel. New price (in 1988) was 65000€, I paid 1400+ had to transport it myself (this is harder than it seems). It’s semi disassembled. It’s an engraving machine not a mill (technically), which is something that I plan to address. But first, story time about how I acquired it!

This is actually a weird size because it isn’t the full fledged industrial C-beam type milling powerhouse, but also way better than pretty much hobby grade machine. Which is exactly what I was looking for, capable, needs a bit of work, but most importantly I can fit it through a door (even though it’s not easy).

I was told that the machine is about 800kg/1750lbs. The exact number is somewhere in the documentation. I got like 10kg paper based documentation with it all in german. I’ll need to dig myself into that which I am not looking foward to very much.

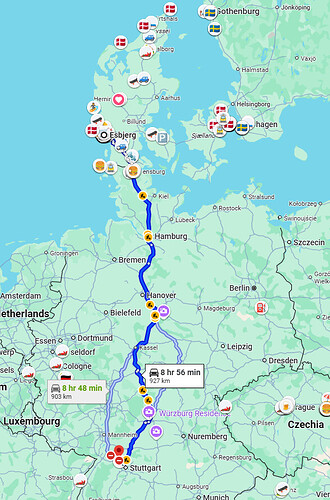

So, to the transportation part. The machine is in south Germany while I live in Denmark.

A 9 hour drive away, right? Very wrong… With a trailer, going slow, taking breaks to regenerate the my brain cells that I lose every moment driving so slow… it’s an insanely long drive. So I went to pickup the trailer:

Turns out the company didn’t have the pallet lifters that their website said they have

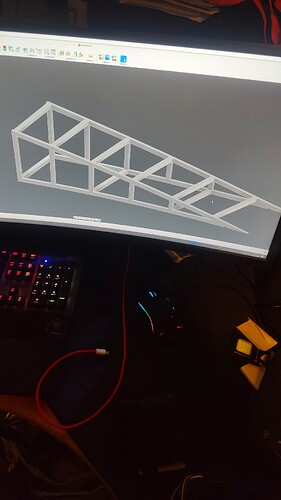

Which is what I was counting on to load the trailer. When I found this out, I was 23 hours away from the discussed time to pickup the machine. So that meant I went to buy some material to build a ramp:

24m of square steel tubing

And a full sheet of plywood plus bricks to put under the trailer to support it while loading, so that it doesn’t flip.

Here’s the rough plan:

Now onto welding.

Yes I know right outside the house isn’t the perfect setup to weld…

But the weld quality turned out decent I think when I was actually paying attention. The ramp turned out a bit crooked, which isn’t an issue, though it definitely shows that at least having flat ground would be really great…

Now to load the ramp into the trailer and start driving:

We are at T-8 hours and no sleep. Remember google maps saying 9 hours? Well that didn’t think about the slight inconvience of a trailer.

So I arrive at T+6.5 hours, taking 14.5 hours on the drive that way, with one hour sleep halfway on the side of the highway, just to reset my body clock. Then we load everything, it took 4 persons to push the wheeled pallets up the ramp, but it was doable.

The rear suspension sits a little low with around 1.3 tonne of trailer weight (most of which is supported by the trailer wheels, but still. It’s within the limits of the trailer and the car, but barely.

Quick stop at the supermarket for some sugar for the way back, then onto driving. I started driving from the supermarket at 8pm, arrived to biltema just after the danish border to pickup an engine crane at around 2:30pm the next day, so that’s another 16.5 hours in the car, of which I slept 2, again on the side of the highway. The handling of the car felt horrible with so much weight behind, so I was driving extra carefully and slowly. After biltema an hour and a half of extra driving to get home.

Here’s what I bought at biltema. The engine crane is required for assembly, and turned out to be required for moving the parts of the machine into the house also. With the engine crane and trailer rental and fuel and ramp I paid around 800€ on transportation! That’s actually quite significant and I was expecting around half of that.

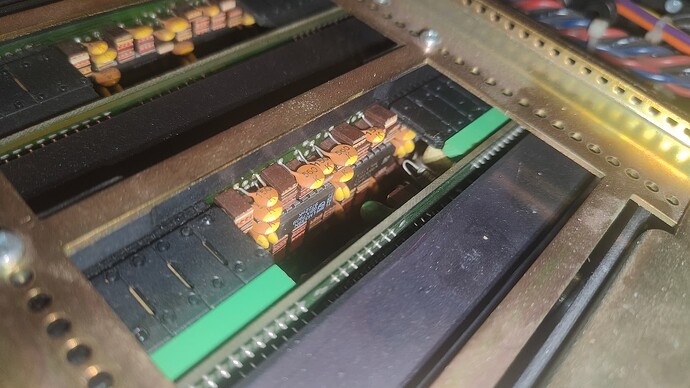

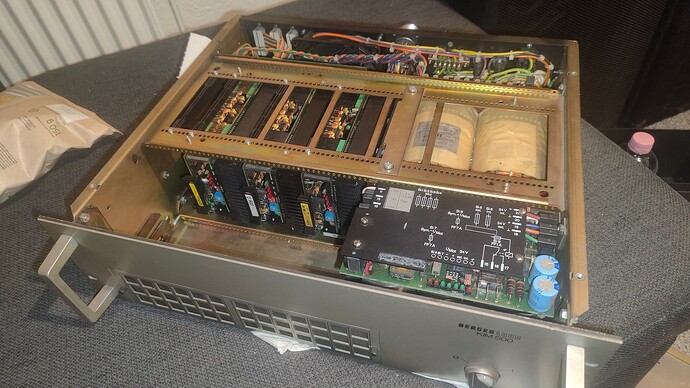

Also look at that electronics:

It’s ancient stuff! The keyboard and the joystick for the controls feels suprisingly nice, definitely keeping that. I guess that’s what 65000€ of late 80s money gets you, keyboard that feels nice after 35 years. ![]() The rest of the electronics setup I want to go through and take a deeper look to find out what’s usable and what isn’t really.

The rest of the electronics setup I want to go through and take a deeper look to find out what’s usable and what isn’t really.

Then onto unloading, which I needed to do right after arriving home. So I started driving to get the trailer 10am wednesday and was going like a machine until saturday midnight, that’s 62 hours. Expecting to wake up to return the trailer by 7am, but I slept through all 10 alarms I set, so I returned it 5 hours late around noon. Then came home and slept again until 6pm.

For unloading we used the ramp and some straps, it wasn’t a big issue. Then we took the parts inside, the bridge and the huge table we needed to flip 90 degree to fit through the door, which we did with the engine crane. Given that I was up like 2 and a half days, I wasn’t really in the mood to take a bunch of pictures.

At this point I left the parts resting inside the kitchen area, I had a long sleep, and we continued 2 days later.

I also have to figure out what to do with the computer that’s supposed to be hanging from the side of the machine, install it or throw it out. I kinda like the industrial look but it’s a fair bit of space. That said I do need some sort of on the machine controls.

What needs to be done to the machine:

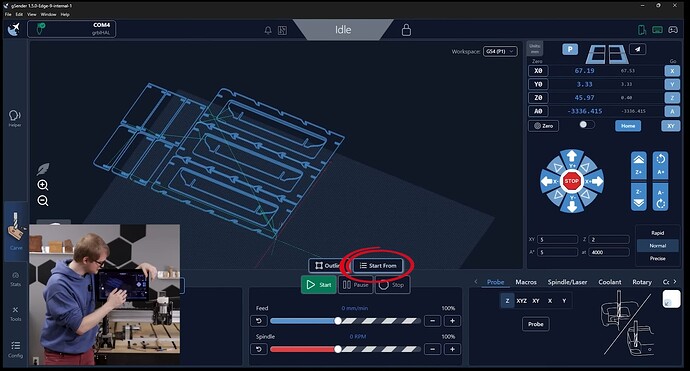

- Assembly: mechanical parts are relatively straight forward. With the stock electronics I’d definitely need to read documentation (in german) so that’s difficult. I was planning on refreshing the control setup anyways, so probably not even worth it to play much with the 35 year old motion control setup. The stepper motors are huge, so I want to look into their documentation to see if I can keep them. Their driver is a 3U rack unit, so there’s definitely meat in the setup. I was originally considering using my nema23 closed loop steppers but they look like a joke compared to what’s on the machine now. So I need to figure out how to communicate with the drivers and see how good the motors are.

- So as mentioned above the motion control setup

- Spindle: as I said above, this is an industrial engraving machine. The weight and good construction makes it very rigid to mill stuff, but the spindle is for engraving, doesn’t really work for milling. This means its a very high RPM spindle (60.000 rpm!) and very low torque. Milling would need much higher torque and less RPM. So a spindle change is needed. I am looking into options. Thinking either trying my luck with a cheap BT30 kit or just getting a relatively cheap 2.2kw chinese spindle to get started and upgrading to proper ATC spindle later down the line.

- Z travel. It has 100mm stock, but bridge clearance from table is 220mm. The Z uses a leadscrew instead of ballscrews and the leadscrew also looks relatively worn (on the XY axis, theres ballscrews and I got extra ballscrews for the future, but the ones on there don’t look worn). So since the spindle mod means taking things apart at the Z axis anyways, I’ll figure out how to increase travel, and get a new ballscrew kit to go with it for the new travel. I am aiming for 180mm Z travel after the mods, though if I can get slightly more, I’ll.

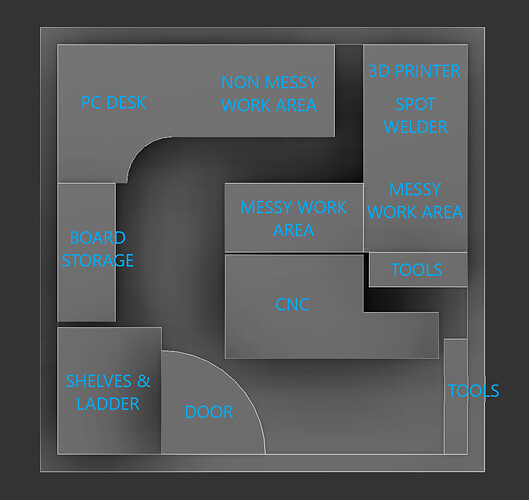

- Enclosure: I definitely want to keep the chips enclosed. I’ll DIY something probably from acryllic and alu extrusions. This needs to happen before I first mill anything.

- Some kind of chip clearing setup is definitely planned but I first want to have something that works and then look into chip clearing. Compressed air is cheap and works, a mist system would be better, or flood coolant would be ideal but messy and more work and need to look into if I can fit that to this machine.

- Buy some endmills and stuff, but that’s straightforward.