Thanks for the shoutout  Looking forward to seeing your build process!

Looking forward to seeing your build process!

Your methods are interesting to say the least, did you solder the wire to the nickel and then weld that nickel to the end of the group or did you solder to the end of the group and then weld nickel over that as a shield?

Also got a bunch of stuff from Ali and Bang

- RD6012W

- Solder fan

- Kapton tape

- Ceramic bearings

- XT60-M

looks sexy! Im curious for some user experience with the charger!

Dude i am so fucking jealous of your table.

I’ll post my thoughts on it when I start using it! Currently I’ve set it up and have it running some led strips, I’m keen to get the wireless features working but haven’t tried yet.

Haha thanks dude, I designed and built it for my high school wood work subject, I used bent laminated legs and Australian blackwood. I drew it up in Sketchup back in the day but the files won’t open anymore lol.

Some parts update:

- @Boardnamics order:

My order from them hadn’t updated once since I ordered on the 7th of September (over 2 months ago!), I realised I should try and see what’s up so I emailed Kevin and he said he had no idea why it never shipped at all since then lol. If this happened to someone else I would guess they’d be justifiably displeased with the service.

Fortunately, I wasn’t too worried since other parts are still yet to arrive. Shit happens and as far as I know, Kevin is a one-man band. To his credit he responded immediately even though his local time was past 3 am, don’t work too hard! Since it hadn’t shipped I took the opportunity to save on shipping costs and ordered some Matrix II mounts for a future build

- @torqueboards order:

Following a similar story, my 6380’s and 110’s hadn’t shipped after some time so I emailed Dex and they informed me that due to the Rona shipping costs had increased, thus I needed to pay an additional $44 usd to cover that.

Given the circumstances I’m fine with that. There’s nothing that competes with their 6380’s and 110’s so I’m perfectly fine paying a premium for what’s considered the best of the best.

- @SimosMCmuffin FlexiBMS:

After a few months the tracking info still says in transit. Hopefully it hasn’t been lost on its way here! Due to the hand crafted nature of the Flexi and also how unattainable they currently are I sincerely hope that it hasn’t gotten lost…

I haven’t died yet, just need some motivation to start this build! Everything is here now, the flexibms never turned up unfortunately… I still need to get onto @SimosMCmuffin about that.

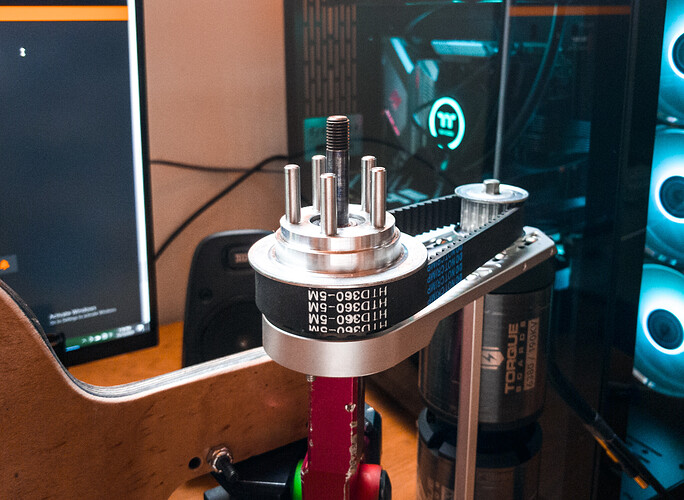

Just threw together some of the drivetrain, the 110’s along with the super wide @Boardnamics axles look fucking sicc. Next on the agenda, fire up the kweld

I’m putting an inquiry to the post office about the status of the shipment.

For what it’s worth…riding the Sportster deck is a massive motivator. It’s a sublime ride feel.

Looks great. Keep on keeping on!

Your wheels look mmmm less blue than mine.

I like

Yes. I soldered the wiring to the nickel first, then spot-welded the nickel together. I swapped out the 6389s with TB’s 6380s so I didn’t have to offset the hangers. My son’s been riding the Biohazard since and hasn’t had any issues. I still need to finish the enclosure: weather seal, grommets, etc., but he didn’t want to wait.

Please tell me there is something in between your battery and the carbon fiber

Excuse me for asking, but what’s in carbon fiber that can short a battery?

Carbon fiber

Oh CF, is naturally conductive. Good to know!

Aight I’m finally starting this build. First thing is to put the battery together.

Is there any step-by-step guide for a flexy pack?

I know I can simply compile the information from here and eventually get there. So far I’ve got:

- Silicon p groups together

- Wrap p groups in fish paper

- Insulate + - with fish paper rings

- Wrap p groups with fibreglass tape (seen some people do this)

- Weld nickel to p groups

- Solder p groups together with 4x 14awg wire (4x 14 gauge allows more flexibility & thinner profile, lower mass & less time needed to solder and transfer heat to batteries)

- Lay fish paper line for balance leads to rest on

- Wire balance leads to each p pack

- Cover balance leads with kapton

- Program Flexi bms (seems real complicated lol)

- Miserably wait for rona restrictions to lift for the metr pro shipping

- Only thing I don’t have is shrink wrap big enough to wrap an entire p group.

Basically this (thanks @Skyart, @bwahl602)

Minus the kewl battery pcb’s

Anything I missed and should keep in mind as a noob battery builder?

Apart from missing kapton tape on all the soldered connections, looks really good!

Edit: I’m an idiot; those aren’t the same battery

One thing people recommend is adding a bit of solder to your nickel in the spots you will need it before you weld it to the cells!

Yep will do that.

Just setting up the Kweld now, will make some test welds on old cells to dial it in.

Been so reluctant to start this because of how much dough I’ve already sunk into this

If my battery looks 10% as good as all the professionals here I’ll be content!