@tech.shit I was like who is this random dude giving me advice? And then I realized it was you ![]()

![]() That profile pic

That profile pic ![]()

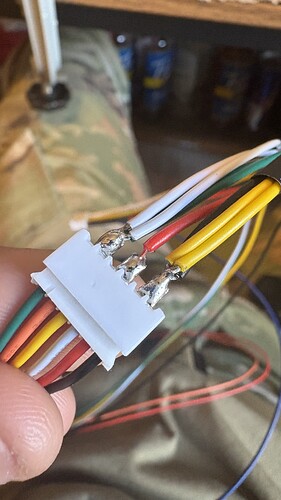

120mm 120v Fan from funny enough an air conditioner.

This one sucks but it’s basically the same thing… and I wired the guts from a 120v led light bulb into it too ![]()

no filter ![]()

Naaa, i run a really big ass hepa filter or two with 20sq ft of filter surface area and then use a fast little fan to keep the smoke out of my face. My air quality is immaculate ![]()

Yes the ralim firmware is fantastic and updating it is easy.

I use one of my LiPo smart chargers set to 10A and 28v if I’m looking for max power. More voltage makes more current flow too so it’s a big difference to about 80 watts. But the iron doesnt draw max power for more than a second even soldering 8awg with a wide tip so I think transferring heat is the issue.

Mine just came in the mail, keen to start using it, any settings recommendations?

Thanks. I had been considering using one of my CCCV voltage boosters, that i use as chargers, to feed my TS101 28v, and get full wattage from it, but thought perhaps the switching noise might screw it up.

I have a cheap, nearly useless digital 110v soldering iron, and was using an inverter, to be able to use a DC inline wattmeter to see the wattage draw, and the Noisy modified square wave prevented the iron from heating at all.

The guy who gave me tips when I was first trying to learn soldering, stressed not having to apply the heat for too long with an underpowered iron, and my mindset is still locked there.

Tucker’s video, I started stressing the time it was taking.

530 Celsius ftw on 8 guage ![]()

![]()

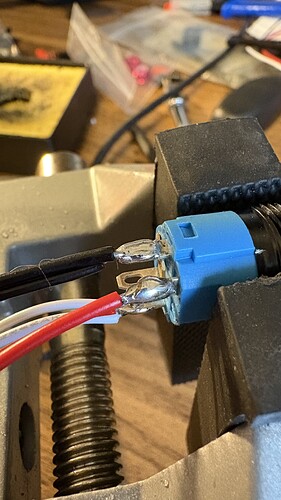

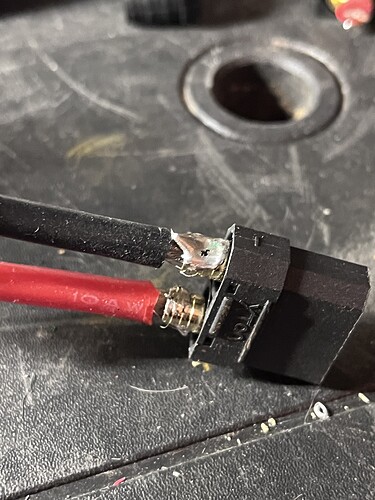

Show us ya crimper! I been soldering my crimp connectors like a savage ![]()

Hydraulic crimper dies are often undersized, allowing for one to easily over crimp, and the dreaded ‘crimp ears’ are the visual result.

I have had a few ring terminal lugs with crimp ears fail. I noticed a lot lower voltage than I was expecting under a high load, and the termnal was fjnger burning hot right at the crimp.

More than half the wire stranding had sheared at the edge of the crimp, and I was able to break the other half off just bending it back and forth.

That said i have other overcrimps with small ears that seem to have no issues. I started dremeling the sharp edges off so the heatshrink was not getting tweaked there, and to hide the ears.

Scroll down to the bottom of this article.

Joints accepted! Impressive!

The door is open for stupid shit as long as joint is involved. So let it rip, the more other people show their ass, the more normal I become. It’s a win for everyone!![]() lets go!

lets go!