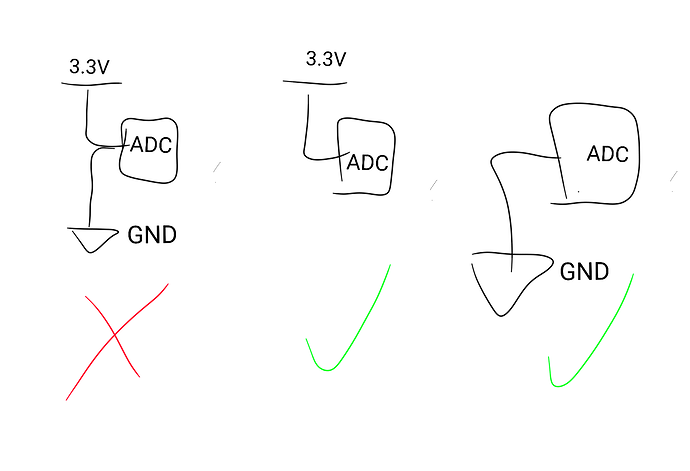

Do not put more than 3.3V on the ADC input pad. They are not 5V rated.

To drive the idea home. When you prepare to accelerate, you lean forward - more pressure on the front foot. When you brace to decelerate, you shift your weight to your back leg. Now if bracing yourself as you normally would causes the board to accelerate or decelerate, that would be ideal.

I’ll definitely update later on whether or not I find it feasible or not. I got a pressure pad to test this already, though it kinda sucked. It couldn’t detect different levels of pressure as advertised, it really only had a high/low signal even though it had every ability to output many levels in-between.

I can imagine a scenario where you may brace yourself by leaning forward but not actually want to accelerate. In such a scenario, you’re probably going through undesirable terrain and keeping a low center of gravity is important. Could have a button perhaps that keeps you at your current speed and ignores the pressure pad.

Or, could have the pad in a spot where you can easily adjust how much your foot rests on it, so you can put more weight on the foot without putting all that weight on the pad.

I can also adjust in VESC Tool how often it reads the input signal. If it reads it every, let’s say, half second, that’s plenty of time to adjust footing without worrying the board will want to stop but still responsive enough.

Well, I’m just blabbing. Probably will blow up in my face and be too much a hassle. But I’ll try anyway.

Thanks for the warning, I almost did input 5v but I noticed that VESC Tools only allowed a maximum input of 3.3v and noticed the VESC gave a 3.3v output for the ADC connector.

You hear lots of same opinions.

Single drives can be a blast for street riding. I wouldn’t take them offroad. Although I have and do. They are also lighter, cheaper, smaller, and have less parts to fail. But they don’t get along with OCD and wanting things to be symmetrical. They fail hard in the “appearance” department.

The word “better” has many meanings. Better for what? They’re definitely not better for showboating. Always mind the goal, whatever it may be.

Heh, thanks for the input. I was planning on off-roading… probably mainly off-roading. I was worried it may be slow in acceleration and braking. But after seeing how strong the motor can brake, I don’t even think that’ll be an issue.

I just don’t know if dual motor’s is considered better because there’s more power, or because there’s a really a huge benefit in allowing the work to go through two wheels instead of just one.

Make sure you do LOTS of research. Lots.

As @xsynatic noted, many have tried this, including commercial boards.

There are very good reasons why people don’t do it regularly and it doesn’t catch on.

But, definitely try it if you want. Just do tons of research because everything you’re talking about has been tried before…

IMHO it’s mostly a traction and appearance thing on DIY skateboards. Sometimes also power, but generally the boards are usually sickly overpowered anyway. Even some of my 1WD are overpowered, IMHO.

If you will be going offroad, you probably want multiple wheels powered.

Heh, I’ll definitely update on how it goes. I have several ideas, but only through testing am I gonna see how feasible they really are. They work great in my head though.

If it doesn’t work, I’ll probably just end up with a remote.

Yea, I’ll definitely see how it feels with a single wheel just to know. I can always upgrade it later down the line. Getting another ESC/motor/battery definitely isn’t a wallet hit I’m looking forward to lol.

Actually, I didn’t originally even buy the motor for the skateboard but I’m repurposing it. Otherwise I’d of considered buying two smaller motors. Either way, this’ll be a fun project!

Time to knock out, good night ![]()

Thanks for all the help, I really appreciate it!

I suggest the rear heelside wheel

I think setting the control to speed would be the easiest way to have this happen but I’m not 100% sure. Having locked up breaks does require pushing current into the motor so it’s not the default setting. Is there a particular reason you want this? It can be helpful to have the board able to move so you can drag, nudge, or normal push it around

Speed control’s downfall is that it will literally suck up to the max amperage to keep the speed and the motor will suddenly jolt to overcome anything. Would probably fall right off the board.

Defaulting to brakes is really more so for my other project rather than the skateboard. But if I make the skateboard controller-less, then there’s no other way to signal to the board I don’t want to move than to not send it a signal. It’s not impossible to have a specific brake button, but would be a hassle and not as safe if you fall off the board (it’ll start rolling away).

It’s also possible I have no idea what kind of input VESC Tools expect as a brake signal ![]()

Only tested with small pressure pads, typically for thumb pressure 0-5kg, so it might be different for big, foot activated pads, but my impression was that they were much less accurate than a quality thumbwheel, or even a cheap scooter thumb throttle. It’s actually very hard to keep a constant squeezing.

Anyway, the main caveat of pressure pads on the board to control speed is that a skateboard evolves in a complex urban environment with small curbs, cracks, pebbles, potholes, and any encounter with those changes the weight distribution on the board, even if only for a short period of time. And carves and hard turns also affect the pressure you put on the board. And you don’t necessarily want the board to accelerate or brake in response to this.

While you experiment, try to limit your motor current in VESC settings to something like 15-20A, so that you don’t get punished too much if the board brakes or accelerates when you don’t want it.

My idea is to have it read an average signal every half second or so that it doesn’t react to sudden temporary changes.

I’m very in love with the idea of being able to control the board in a non-wireless way. Lose the remote, battery dies on the remote, you fall and break the remote, etc. are all avoided. And I think you’d be able to better catch yourself in a fall if your hands are free anyway.

Also looking at bathroom scale sensors. Amazon has a deal for 4 + A/D converter for $8. A steal.

Got some other things to do, but I’ll be testing ADC soon!

You can use PWM (cannot be inverted)(center and ends can be adjusted)

- <1.5ms is brake

- 1.5ms is idle

- >1.5ms is throttle

You can use an analog signal, 0V to 3.3V max (can be inverted)

- below setpoint is brake

- at setpoint is idle

- above setpoint is throttle

You can use two analog signals, each 0V to 3.3V max (both can be inverted)

- above setpoint on channel 2 is brake

- above setpoint on channel 1 is throttle

About to test out ADC. The input for it seems very simple and specifically says that idle can be set to brake. On PWM, brake just kinda happened if you tried to go to reverse when still going forward.

Hoping braking works! I’ll update.

Well, this is one of the worst day’s I’ve had in a while. Was looking forward to testing and I find out the cables I got are slightly different than what I needed.

I still wanted to try it out so I got a wire and shorted the 3.3v straight to ADC1 and then shorted ADC1 to ground to get a reading range with the center at 1.4v (for some reason that’s the voltage it reads with nothing plugged in).

Now if I short 3.3v to ADC1, the motor spins up. When I short ADC1 to ground… it gives the same braking power as when using PPM input.

What I realized is that the braking is not actually weak, it just doesn’t care about stopping itself at low RPM. When I manually spin the motor fast, it increases current significantly and tries to stop it. It’s very gentle.

I’m really looking for that super powerful braking I got when I had it on DC mode.

So I tried BLDC even though it didn’t work properly with PPM. The braking was a lot stiffer and felt better! It wasn’t as good as the DC mode braking, but I’m sure that could be fixed later.

Since I didn’t know if BLDC mode would move the motor, I shorted 3.3v to ADC1, which I knew was a bad idea but I only wanted to touch it for a second. Motor nearly gave me a heart attack.

That’s enough testing until I get the proper cable…

Oh no please don’t do that! This is a short directly to ground, and will definitely damage the board. How long did you hold it like this? The wires should have started heating up very quickly if the 3.3V didn’t cut out. Use resistors to split voltages, it’s called a voltage divider

The output of the connection has a 5v output and a 3.3v output. I assume that the 3.3v output is fine to short to the ADC1 pin as its the signal output that’s expected by it anyway.

The 5v pin is the one that shouldn’t be directly shorted to ground or any other pin. Though, I did accidently short the 3.3v to ground which caused the ESC to restart ![]() .

.

I think it might be a language thing, I assumed you mean the first setup where 3.3V is shorted to both ADC and ground but maybe I’ve misread. If it’s short 3.3, remove 3.3, short ground, then yes you’re right

When you say the connection, do you mean from your micro to the VESC ADC? I re-read the thread to try and find a specific interface or something you’re referring to but I’m still a bit hazy there. For my understanding do you mean the micro can set its PWM/DAC output to be 5v logic and 3.3v or is it like a prebuilt throttle controller off an ebike or something?

To expand on this a bit, I think the issue with a pressure control rather than a onewheel-style balance control, is that the actual pressure vs what the rider feels they’re inputting as “pressure” is nonlinear with a bunch of other parameters. On a onewheel your feet adjust to keep stuff balanced as the surface, speed, and rotations in other axes change, and what the system is measuring is the output of this big dynamic system (the lean or how level the board is) vs just one of the inputs (the pressure between feet and pad). So as Alex said, basing the throttle off pressure accidentally responds to changes in other stuff like turn and slope instead of rider’s intent to accelerate. Usual disclaimer, not a proper expert and happy to be corrected here

I assumed you mean the first setup where 3.3V is shorted to both ADC and ground

Oh, not at all. I only had one wire. I shorted 3.3v to ADC1 to get the high signal, then took the same wire off to then short ADC1 to ground to get the low signal.

When you say the connection, do you mean from your micro to the VESC ADC?

I mean the ESC has a port that offers 5v, 3.3v, ground, ADC1, and ADC2 pins. The 5v is to power whatever you connect to it, and the 3.3v is the signal it expects to be rerouted to the ADC pins.

My microcontroller is a Raspberry Pi Pico which, sadly, can’t regulate how much voltage it gives out like that. It can either output 5v, 3v, or output PWM at a lower voltage. I did want to try and have it regulate voltage, but just isn’t something it can do.

So as Alex said, basing the throttle off pressure accidentally responds to changes in other stuff like turn and slope instead of rider’s intent to accelerate.

My idea is to fix this through pad placement and other little tricks. If indeed it turns out to not be viable, then I won’t stick to it. But the idea seems sound enough in my head that I have to at least try!

At the end, I may have a board that would not be able to accommodate anyone else but me due to all the adjustments, but I wouldn’t mind.