Slope in just the tangent of the angle, tan(45°) = 1 = 100%, tan(10°) = 0,176 = 17,6%

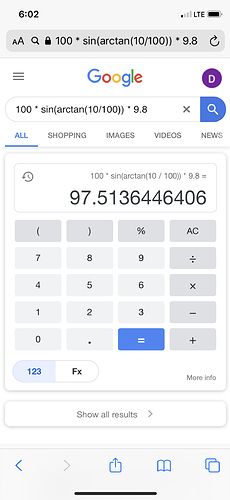

you can calculate the downhill acceleration force in newtons or the amount of force it takes in newtons to hold a 100kg mass steady or at constant uphill velocity on a frictionless 10% (10/100) slope in a vacuum on earth (gravity acceleration = 9.8m/s^2) via:

force_newtons = mass_kg * sin(arctan(rise/run)) * acceleration_gravity_meters_per_second_squared

97.5 newtons = 100kg * sin(arctan(10/100)) * 9.8m/s^2

1 newton = 0.102kg force

so

9.94kg force = 97.5 newtons

I see on the vesc toll duty cycle set on 95% I assume it is for safety reasons? Should I / could I set it to 100% ?

I understand it, I have just never seen it used, or have not thought about it when using it in physics.

vescs do 95% duty max… it uses the other 5% time to take current measurements.

Thanks for that nice summary.

While this might be trivial in BLDC mode, things in FOC seem to be a lot different.

Can you explain how I get value pairs like :

144.6A Motor current

105A Battery current

at 95% duty.

(these were recorded by a VESC75/300 R2, so I didnt consider measurement errors…yet)

So my understanding was like:

Battery current * sqrt(2) = Motor current

Because (i thought) motor current is the sinusoidal peak current and to get the RMS you divide it by the square root of 2.

My calculator tells me that something is wrong: 105A*1,41 = ~148A. Which is a bit far from the recorded ~145A.

But things in the code also look much different…

The motor current gets calculated like:

state_m->i_abs = sqrtf(SQ(state_m->id) + SQ(state_m->iq));

(so I dont really see the sinusoidal peak here

)

)

And the Battery current gets calculated like:

state_m->i_bus = state_m->mod_d * state_m->id + state_m->mod_q * state_m->iq;

So battery current is: percent of i_d + percent of i_q. Which kind of makes sense since it is absolute state of current being fed, independent of the motor momentary powered phases. Just how the current is split at the moment and by the mod you get the percentage of Voltage in combined with the split between d and q current.

Still I dont get what the motor current represents then, it does not seem to be the sinusoidal peak if you look at the code. Still if you look from the power side: 95%*145A is way beyond the input of 105A.

So could you please enlighten me/us?

I will say I am not an expert in FOC and the math is much more complex.

That said, I have attempted to do some calulations.

My understanding is to get the instantaneous torque its:

KT * RMS_Motor_Current * 1.5 = Newton_Meters_Torque_FOC

&

KT = 60 / (2 * pi * KV_rpm_per_volt)

I assume the 1.5 is because all 3 phases are utilized simultaneously instead of 2 in BLDC. I assume the motor current displayed is the peak current, so to get the RMS, you divide it by sqrt(2).

Then what I did was calculate the resistive losses per phase for a given RMS current based on the resistance, and multiply it by 3.

Once you know the total resistive losses, and you know the torque, I believe you can find the electrical wattage from:

Resistive_Losses_watts + (torque_nm * angular_speed_rad_sec) = Electrical_Wattage

Once you know the electrical wattage, you can divide it by the battery voltage to get the battery current.

well, the relationship between motor and battery current is independent of the voltage. It has to be a fixed relation.

In case of BLDC:

if:

and:

then:

battery_current = duty_cycle_bldc * motor_current

But I don’t see the relation in FOC mode…

there isn’t the same relationship between duty cycle, motor current, and battery current in FOC as in BLDC, and I don’t know what it is.

but you can be sure that to a close approximation, the total instant resistive losses in the motor + mechanical wattage output equals the electrical wattage.

^to prove this lets look at the earlier BLDC example:

^we need to know the resistive losses, torque, and angular speed to calculate the electrical wattage

resistive losses: 20a^2 motor current * 0.05ohm two phase resistance = 20w

KT = 60 / (2 * pi * 190kv) = 0.05025

torque = 20a motor current * 0.05025KT = 1.005 newton meters

angular speed (rad/sec) = (2000rpm * 2 * pi) / 60 = 209.439 rad/sec

mechanical output watts = 209.439rad/sec * 1.005 newton meters = 210.486w

electrical wattage = 210.486w mechanical + 20w resistive = 230.486w

^the resistive losses + mechanical output equals the pwm effective voltage times the motor current equals the battery voltage times the battery current

(the small difference between the 2 values is a rounding error caused by me not using enough decimal places in my calculations)

Is there any appreciable power factor in bldc motors? Like in AC motors where there is a power factor of .85 or .9 because current and voltage are out of phase.

other losses not factored here include iron losses from eddy currents in the stator, controller losses, battery losses, bearing and rolling resistance losses, but my understanding is these losses are less significant than the resistive losses, which is why I said “to a close approximation.”

In AC induction motors, the power factor isnt really lost, its the real power delivered divided by the volts*amps. I recall the power company cares because if the power factor is low, like .9, 10% more amps are needed for the amount of shaft power delivered.

It’s a big deal in the AC world, but I wonder is it significant with bldc motors? I don’t know how we would tell, maybe benjamin knows? It definitely real power coming out from the battery volts*amps. But if there is a lot of reactive power in the 3 phases of the bldc motor, we might see significantly (10-15%) more amps than we would expect given the input power from the battery. Like we might calculate (3phase sinusoid amps * 3phase sinusoid battery_volts * throttle%) > battery_amps * battery volts. Which would be wierd but not if power factor is happening.

kinda related battery question:

When we calculate the Wh, we do nominal 3.6v * 10ah = 360Wh

But since battery full is 4.2v and cutoff is 3.0v, isn’t our “usable” Wh a lot less? 4.2v10ah - 3.0v10ah = 120Wh?

thanks

I was thinking more about this. Although the motors we use are driven by “AC” they aren’t what are normally referred to as “AC motors,” which generally means induction motors. The motors we use on skateboards are not “induction motors“, they are synchronous permanent magnet motors.

The “induction motors” powering factories are less efficient than the motors we use, in part because in addition to armature current producing a magnetic field in the stator, this magnetic field has to in turn “induce” a “secondary” magnetic field in the rotor, and it is the interaction between the stator field and the induced rotor field that makes an induction motor work with no permanent magnets.

I am not entirely certain, but strongly suspect it is the “secondary” field that is responsible for the the current and voltage being more out of phase in AC induction motor, hence the “power factor” but I believe this is significantly less of an issue in the synchronous permanent magnet motors we use in skateboards, which are more efficient than “ac induction motors.”

Cell capacity is usually calculated from 4.2v down to 2.8v - 2.5v depending on the cell, not calculated with discharge to 0v.

So, if your cutoff end is 3.0v, just slightly less than the 360wh in your example, not the low 120wh from your example. I set my cutoff start to 3.0v and end at 2.8v so if I run to 0% I’d get the 360wh from your example and ESC monitor confirms this.

Thank you for your explanations!

Might you mind to share the spreadsheet or code you used to make the charts?

After reading a good portion of @glyphiks’s conversation on battery vs motor amps with @professor_shartsis over remote beer, I have a better understanding, or so I think. I would love to test if my takeaways are correct?

when accelerating at slow speed (low duty cycle):

- the delivered power is limited by how many amps your motor can handle, Whereas battery amps are negligible until they are less than duty cycle times motor amps.

- This seems to lead to the conclusion that for maximal torque, you need beefy motors rather than a big battery. Though I think this might be misleading, as this is only at the very beginning of the duty cycle, close to standing still, where you anyways might want a smoother acceleration. As you move out of this region quickly, battery amps become limiting.

major part of the duty cycle (mid band):

- Battery amps are limiting.

close to top speed (high duty cycle):

- The delivered power is simply limited by the back emf forcing the motor current down.

- We can only shift where this point happens by by reducing gearing at the expense of torque.

(This is assuming that voltage is already maxed out for the ESC.)

So, when designing a build, what proportion of total motor amps to total battery amps do you choose to go with?

It seems that for his candy crusher, @longhairedboy uses a ratio of 1:2 (combined with a rather low gearing ratio of 1:2 on 100mm wheels, 12s battery).

That seems fairly common. But is that by design or just because it happens to be the resulting specs of the most popular parts combinations?

@PrivacyDoctor in practice the delivered power is limited by the software settings you choose.

a motor that’s not supposed to be able to take more than 60amps motor current could be supplied with 120a motor current if that’s what you input in the settings. early vescs have firmware limiting motor current to 120a.

the recommended “limits” are typically determined by how much continuous current will cause something to overheat, not how much current you could theoretically supply which could be thousands of amps in the case of a short circuit.

think of the battery as a fire hydrant with a certain pressure, and the vesc as a fire hose with a valve and the motor as a water wheel at which you are aiming the hose… when you input the motor and battery current limit settings you are telling the vesc how far to open that valve when you fully depress the throttle.