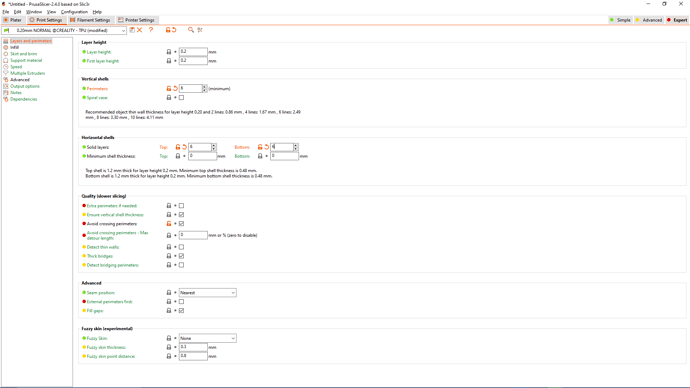

My CR-10S is pretty aggressively modified, so YMMV, but here

There’s low likelihood that plugging in all my numbers into your printer will actually work for you. A better way is to go here https://teachingtechyt.github.io/calibration.html#intro (props to @DeadLightning) and run a thorough calibration. Highly highly worth the time, and it doesn’t even take that long. Printer x filament combo is too unique to use someone else’s numbers in and go