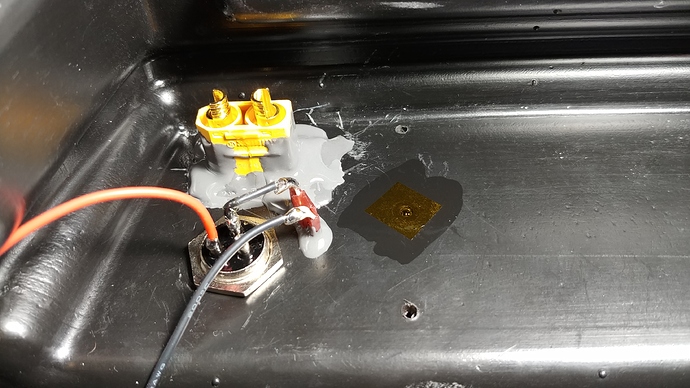

I think it looks fine. Don’t forget the fuse.

What bms is it?

Yes, I would solder a fuse inline with either the black or red wire

https://www.mouser.com/ProductDetail/576-099707.5WXN

It’s saved me at least twice

A 7.5A fuse is fine for up to 4A charging

can you post a link or explaine how i do that?

I would potentially insolate the positive wire all the way to the base of the port. That nut could potentially vibrate loose over time and land on top of the solder joints of the + and - terminal and create a short.

I usually put threadlocker on there to prevent that — and then cover the exposed electrical connections with MG Chemicals #419D Acrylic conformal coating in the 55ml bottle with brush-cap (not separate brushes on the side)

yes of course.

Does hot glue work?

In Australia (i am aussie) you have all those commo things like liquid tape etc but in france you just can’t find it. you have to use amazon

I don’t personally think there is any place in an esk8 where hot glue is the best tool for the job.

You could use neutral cure silicone like “GE Silicone 2+” in the paint section at the local home improvement store, but then it will not be serviceable. The conformal coating is designed that if you need to, you can solder through it then reapply it again.

Brian Can you link me what type of epoxy this is

And what is the difference between #419D and

this

Edit i can just saw that they are basicaaly the same. the 419d is more suitable for my application. Ans the 4223 is highly toxic. I mean both are toxic but the 4223 is really bad.

4223 - URETHANE CONFORMAL COATING

4223 is a one-part, fast drying, thermoplastic polyurethane conformal coating. It cures to a durable, flexible, scratch resistant and smooth finish. It is easy to apply and can be handled in 15 minutes. It may be removed with appropriate strippers, or soldered through for repair or rework.

4223 protects printed circuit boards in extremely corrosive environments. It protects against moisture, fungus, dirt, dust, thermal shock, abrasion, short circuit, high-voltage arcing, and static discharge.

Warning: This product contains 2-butanone, oxime (MEKO); therefore, use in a well-ventilated area and continue ventilation for 10 minutes after use.

419D - PREMIUM ACRYLIC CONFORMAL COATING

419D is a one-part, acrylic conformal coating that cures to a durable, flexible and smooth finish. It is easy to apply and can be handled in 10 minutes. It may be removed with appropriate strippers, or soldered through for repair or rework.

419D creates a robust moisture barrier that protects printed circuit boards in humid environments. It strongly protects against moisture, corrosion, fungus, dirt, dust, thermal shock, short circuits, high-voltage arcing, and static discharge.

Features and Benefits

- Certified UL 94V-0 (File# E203094)

- Qualified to IPC-CC-830B by Pacific Testing Laboratories

- Xylene and toluene free

- Fluoresces under UV-A light

- Validated for selective robotic coating equipment including PVA and Nordson ASYMTEK

Just tried it with the motors and both reacts the same as per the ABC description

So there might be no issues with the phase? I check the cables and don’t see any split/exposed ends as well

My jst-ph 2.0mm 6 pins connectors just arrived for my motor sensor wires. What order should the wires go into the connector? My motor has 5 wires and the connector (and Focbox Unity) 6 pins.

It’s JB Weld 8265-S Original Formula “Steel” epoxy in the 1oz tubes

I like the 4223 only for loop keys and 419D everywhere else. I miss 419C so much. It’s out of production. It was like 419D – except really thin and dries in 30 seconds.

I can’t stress enough – ask the seller before you buy. Get the cap-brush and NOT a cap with brushes on the side.

Right! Do you know the answer to my question above?

What question?